When it comes to stainless steel, 18-8 stainless steel, particularly the 304 grade, stands out as one of the most versatile and widely used materials across numerous industries. Known for its exceptional balance of strength, corrosion resistance, and machinability, this alloy’s properties make it a top choice for a multitude of applications, ranging from kitchenware to industrial equipment. A key factor that contributes to its versatility is its density—a critical physical property that plays a significant role in determining its structural and functional performance.

This article dives deep into the topic, providing a thorough exploration of the density of 304-grade stainless steel, its chemical composition, and its mechanical properties in practical scenarios. Furthermore, we will discuss real-world applications that demonstrate its adaptability and reliability in different industries. By the end of this piece, readers will not only gain a comprehensive understanding of 18-8 stainless steel’s characteristics but also appreciate its impact on modern engineering and design.

What is 18-8 stainless steel and its relationship to 304 grade?

18-8 stainless steel is a term primarily used to describe a group of stainless steel alloys that contain approximately 18% chromium and 8% nickel. This composition provides excellent corrosion resistance, durability, and a polished finish, making it ideal for a variety of applications. The term “304 grade” specifically refers to the most commonly used type of 18-8 stainless steel. While all 304-grade stainless steel falls under the 18-8 category, not all 18-8 stainless steel alloys are strictly 304 grade, as slight variations in composition can differentiate them. However, their shared properties ensure adaptability and widespread use across industries.

Understanding the composition of 18-8 stainless steel

The term “18-8” stainless steel refers to its composition, specifically containing approximately 18% chromium and 8% nickel. These elements work synergistically to enhance the steel’s properties. Chromium contributes to corrosion resistance by forming a protective oxide layer on the surface, while nickel improves the material’s strength, ductility, and resistance to oxidation. This balanced combination makes 18-8 stainless steel durable, non-magnetic in its annealed state, and highly versatile. Additionally, small amounts of carbon, manganese, silicon, and other trace elements may be present, which further optimize the alloy for usability in environments requiring both resilience and aesthetic appeal.

How 18-8 stainless steel relates to 304 grade

18-8 stainless steel is essentially a category of stainless steel that includes alloys with 18% chromium and 8% nickel. Grade 304 stainless steel falls within this category, making it one of the most commonly used types of 18-8 stainless steel. The “304” designation refers to a specific standard set by organizations like the ASTM and SAE, ensuring consistent composition and performance. While all 304 stainless steels are 18-8 by definition, not all 18-8 stainless steels are labeled as 304, as variations in composition or certification may apply. Both are widely praised for their excellent corrosion resistance, strength, and versatility in applications ranging from kitchen equipment to industrial components.

Key properties of 18-8 stainless steel

Corrosion Resistance

18-8 stainless steel is renowned for its exceptional resistance to corrosion and oxidation, making it an ideal material for use in both indoor and outdoor environments. It resists rusting even in moist or humid conditions, thanks to its high chromium and nickel content.

Durability and Strength

The alloy exhibits excellent mechanical strength and durability, balancing toughness with flexibility. Its ability to withstand wear, pressure, and extensive use makes it suitable for a wide range of applications, including industrial and household settings.

Heat Tolerance

18-8 stainless steel performs well at high temperatures, maintaining its structural integrity and resisting deformation. This heat tolerance makes it popular in applications involving thermal exposure, such as cookware and exhaust systems.

Non-Magnetic Properties

While not entirely immune to magnetism, 18-8 stainless steel is largely non-magnetic in its annealed state. This property makes it valuable in certain specialized uses like electronics and medical instruments where minimal magnetic interference is crucial.

Ease of Fabrication

Thanks to its composition, 18-8 stainless steel can be easily machined, welded, and formed into various shapes. It supports complex manufacturing processes, including deep drawing and machining, without compromising its structural integrity.

Hygienic and Food-Safe

Given its resistance to corrosion and ease of cleaning, 18-8 stainless steel is widely used in food processing and kitchen environments. It does not react with food or beverages, maintaining safety and flavor integrity.

These key properties contribute to the alloy’s versatility, allowing it to be utilized in applications ranging from medical instruments and automotive parts to kitchenware and architectural structures.

What is the density of 18-8 stainless steel (304 grade)?

The density of 18-8 stainless steel, also known as 304 grade stainless steel, is approximately 8.0 g/cm³ (grams per cubic centimeter) or 8000 kg/m³ (kilograms per cubic meter). This property contributes to its durability and widespread use across various industries.

Calculating the density of stainless steel 304

The density of stainless steel 304 can be calculated using the value of 8.0 g/cm³ (grams per cubic centimeter) as its density value. This indicates that the mass of the material can be calculated by multiplying the volume of the material with the density. For example, the mass for a stainless steel 304 object which has a volume of 50 cm³ would be:

Mass = Density × Volume

Mass = 8.0 g/cm³ × 50 cm³ = 400 grams.

In the same way, if volume is given in cubic meters (m³), the value of 8000 kg/m³ can be used for density. The value of density for stainless steel 304 does not change under standard conditions, which is appropriate for industrial and engineering measurements.

Factors affecting the density of 18-8 stainless steel

The density of 18-8 stainless steel, commonly measured as 8.0 g/cm³ or 8000 kg/m³, can be influenced by several key factors, though it remains relatively stable under standard conditions.

Temperature Variations

Changes in temperature can lead to thermal expansion or contraction, slightly affecting the material’s density. At higher temperatures, the material may expand, reducing its density, while at lower temperatures, contraction can lead to a minor increase in density.

Alloy Composition

Variations in alloying elements such as chromium and nickel can subtly alter the density. While 18-8 stainless steel consistently contains approximately 18% chromium and 8% nickel, even slight deviations in these levels can have an impact.

Manufacturing Processes

Specific manufacturing techniques, like cold working or annealing, can influence the material’s internal structure, leading to minimal density changes. These processes may introduce stress or modify the crystalline structure, further affecting the overall material properties.

Understanding these factors is crucial for precise engineering applications, as they ensure accuracy in calculations where material density is a critical variable.

Comparing density to other stainless steel grades

The density of stainless steel varies slightly depending on its grade, composition, and manufacturing process. For example, the widely used 304 stainless steel has an approximate density of 8.00 g/cm³, while grade 316, often chosen for its enhanced corrosion resistance, shares a similar range at about 7.98 to 8.00 g/cm³. Duplex stainless steels, known for their dual-phase structure, tend to have slightly lower densities, typically falling between 7.75 and 7.80 g/cm³ due to their mixed ferritic and austenitic composition. On the other hand, ferritic grades such as 430 are denser, often around 7.70 to 7.80 g/cm³, benefiting from their higher chromium content and minimal nickel.

These variations, though minor, can influence material selection in applications where weight is a factor, such as aerospace or automotive parts. By carefully comparing the densities of different grades, engineers can optimize product performance without sacrificing strength or durability. The choice of grade must balance these physical properties with other crucial factors like corrosion resistance, mechanical strength, and cost-effectiveness.

How do the physical properties of 18-8 stainless steel impact its applications?

The physical properties of 18-8 stainless steel make it ideal for a wide range of applications. Its excellent corrosion resistance ensures longevity in harsh environments, while its high tensile strength provides durability for structural and load-bearing uses. Additionally, the alloy’s ductility and ability to withstand high temperatures allow it to be used in both flexible and high-heat applications, such as industrial equipment, food processing machinery, and medical devices. These attributes, combined with relatively low maintenance requirements, make 18-8 stainless steel a versatile and cost-effective choice across numerous industries.

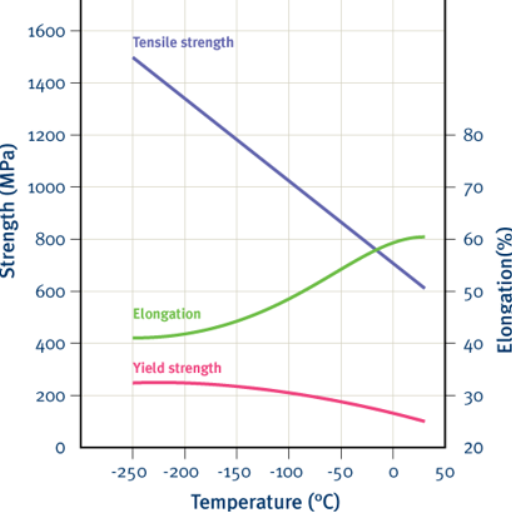

Tensile strength and yield strength of 304 stainless steel

304 stainless steel is highly valued for its impressive mechanical properties, making it a popular choice across industrial applications. The tensile strength of 304 stainless steel typically ranges from 70,000 to 80,000 psi (approximately 485 to 620 MPa), which indicates the maximum stress it can withstand before breaking. Its yield strength, which measures the stress level at which the material begins to deform permanently, is approximately 30,000 to 40,000 psi (around 205 to 275 MPa). These properties are influenced by factors such as temperature, processing methods, and specific alloy composition. Thanks to its balance of strength and ductility, 304 stainless steel performs effectively in demanding structural, mechanical, and environmental conditions.

Corrosion resistance capabilities of 18-8 stainless steel

18-8 stainless steel, including its common variants such as 304 and 316 grades, is renowned for its excellent corrosion resistance due to its high chromium (18%) and nickel (8%) content. This composition forms a passive oxide layer on the steel’s surface, protecting it from oxidation and corrosive environments. It performs exceptionally well in various conditions, including exposure to moisture, acids, and some industrial chemicals. However, its resistance may reduce in environments containing chlorides, such as saltwater, where pitting corrosion can occur. To enhance corrosion resistance in chloride-rich settings, molybdenum-alloyed variants like 316 stainless steel are often preferred. Ultimately, 18-8 stainless steel remains a reliable choice for applications requiring durability and protection against corrosion.

Magnetic properties of 304 grade stainless steel

The Austenitic 304 grade stainless steel is non-magnetic in its annealed state, meaning it can be magnetically affected only on the surface. This is due to the crystal structure that is present in the material. However, some magnetic properties can develop as a result of cold working, welding or any other process that transforms the non-magnetic austenite phase into the magnetic martensitic phase. Even though the amount of magnetism that is produced is usually weak, it can change based on the mechanical or thermal energy that is applied to the material. For other applications that require very low levels of magnetism, other types such as 316 stainless steel can offer great alternatives as they exhibit very weak magnetism even after cold-working.

What are the common applications for 18-8 stainless steel?

18-8 stainless steel is highly versatile and widely used across numerous applications due to its excellent corrosion resistance and mechanical properties. Common applications include kitchen utensils, food processing equipment, chemical equipment, medical instruments, and architectural structures. Its durability, ease of fabrication, and resistance to rust make it a preferred choice in both industrial and consumer settings.

Use in food processing and kitchen equipment

18-8 stainless steel is ideal for food processing and kitchen equipment due to its non-reactive surface, which prevents contamination and preserves the quality of food. Its high corrosion resistance ensures longevity, even when exposed to acids, salts, or high moisture conditions commonly found in kitchens and food production environments. Additionally, the material’s smooth finish makes it easy to clean and sanitize, meeting stringent hygiene requirements. From mixing bowls and cutlery to large-scale production machinery, 18-8 stainless steel is a reliable and efficient choice for maintaining safety and durability in food-related applications.

Industrial applications of 304 stainless steel

304 stainless steel is one of the most versatile and widely used stainless steels across various industries due to its excellent corrosion resistance, strength, and ease of fabrication. It is a preferred material for the chemical, petrochemical, and oil industries, where it is used in tanks, pipes, heat exchangers, and chemical containers because it can withstand harsh chemicals and extreme temperatures.

Additionally, the construction and architecture sectors often utilize 304 stainless steel for structural components, facades, and decorative features, as it resists rust and maintains a sleek appearance even in outdoor or high-stress environments. It is also indispensable in the medical and pharmaceutical fields, providing hygienic surfaces for surgical instruments, sterilizers, and cleanroom equipment. From industrial machinery to everyday products, 304 stainless steel demonstrates its adaptability and reliability in rigorous environments.

Architectural and decorative uses

Due to the inherent strength, durability, and resilience of 304 stainless steel, it is widely utilized in architectural works and is now a staple in interior design. Steel can be used for construction purposes both indoors and outdoors. Unlike other types, this steel is able to withstand extreme weather conditions which makes it corrosion resistant. Typically, it can be used for sleek modern buildings for cladding, railings, and other structural supports.

Additionally, as wall panels, it is extremely popular for sophisticated furniture and sculpture art. 304 stainless steel provides these artisans with an easy finishing option due to the polishability, enabling them to elevate the design and practicality of their work without hassle.

How does the density of 18-8 stainless steel compare to other materials?

An 18-8 stainless steel has a density of roughly 8.0 g/cm³, which is higher than aluminum’s density of about 2.7 g/cm³. Its density is lower than pure iron, which has a density of 7.87 g/cm³ while being vastly less dense than lead at 11.34 g/cm³. The 18-8 stainless steel’s moderate density coupled with strength and corrosion resistance makes it ideal for applications where weight and durability are both important.

Comparing 304 stainless steel density to other metals

When looking at the density of stainless steel 304 in relation to other metals, its versatility is apparent. Stainless steel 304 with a density of roughly 8.0 g/cm³ strikes an excellent balance between strength and weight, making it preferred in construction, automotive, and aerospace industries. While lighter materials like aluminum (2.7 g/cm³) have some advantages, stainless steel is far stronger and more durable, though heavier. Conversely, stainless steel is lighter than high density metals such as lead (11.34 g/cm³) which makes it practical for use where strength is required without excessive weight. Stainless steel 304 also has a density closely aligned with iron (7.87 g/cm³) but unlike iron, 304 stainless steel has better corrosion resistance and longevity, making it ideal for use in moist or chemically aggressive environments. This combination of properties makes 304 stainless steel a critical material in many fields where low weight and high resilience are needed.

Impact of density on material selection for various applications

Density plays a pivotal role in material selection across various industries as it directly influences weight, strength, and overall performance. For applications in aerospace and automotive industries, low-density materials like aluminum and titanium are often favored due to their lightweight nature, which enhances fuel efficiency and reduces structural loads. Conversely, fields such as construction and heavy machinery may prioritize denser materials like steel or concrete for their robustness and ability to support significant weight. Additionally, industries dealing with precise manufacturing, such as electronics, consider density in relation to thermal management and component durability. Ultimately, understanding the relationship between density and application-specific requirements ensures optimal material performance and cost-efficiency.

What are the mechanical properties of 18-8 stainless steel?

18-8 stainless steel, which includes grades like 304 and 316, is widely recognized for its excellent mechanical properties. It offers a tensile strength ranging from approximately 515–720 MPa and a yield strength of around 205–250 MPa, depending on its condition and processing. This material exhibits exceptional corrosion resistance due to its high chromium (18%) and nickel (8%) content, making it ideal for environments exposed to moisture or corrosive substances. Additionally, it has good ductility and toughness, even at cryogenic temperatures, and displays impressive work hardenability, which further enhances its strength when cold worked. These properties make 18-8 stainless steel a versatile choice across industries like construction, food processing, and marine applications.

Understanding the strength and durability of 304 grade

The 304 grade of stainless steel is renowned for its combination of strength, durability, and corrosion resistance. With a tensile strength of approximately 505 MPa and a yield strength of around 215 MPa, it provides robust performance under various conditions. Its high chromium (18-20%) and nickel (8-10.5%) composition contributes to its exceptional resistance to rust and corrosion, particularly in settings exposed to moisture, chemicals, or saltwater. Additionally, 304 stainless steel maintains excellent ductility and toughness across a wide temperature range, including cryogenic conditions, making it suitable for both industrial and domestic applications. The material’s strong work hardening properties further allow it to withstand heavy use and wear, making it ideal for products like kitchen appliances, structural components, and medical equipment. Its cost-effectiveness and versatility cement its position as one of the most commonly utilized stainless steel grades in the world.

Elasticity and hardness of 18-8 stainless steel

18-8 stainless steel, which includes alloys like 304 and 316, exhibits a balance of elasticity and hardness that supports its widespread use in various applications. Its elasticity is characterized by a Young’s modulus of approximately 193 GPa (28 million psi), allowing it to endure moderate deformation under stress while returning to its original shape once the force is removed. The hardness of 18-8 stainless steel typically falls within the range of 70-90 HRB (Rockwell Hardness B-scale) in its annealed state, though this can increase significantly with cold working, enhancing strength and wear resistance. This combination of mechanical properties makes it a reliable choice for applications requiring both resilience and durability, such as springs, fasteners, and precision components.

How does the chemical composition affect the properties of 18-8 stainless steel?

The chemical composition of 18-8 stainless steel, primarily consisting of approximately 18% chromium and 8% nickel, significantly influences its properties. Chromium enhances corrosion resistance by forming a protective oxide layer, while nickel improves toughness and ductility, making the alloy more adaptable to varying mechanical stresses. Additionally, the balance of these elements ensures excellent weldability and resistance to high-temperature oxidation, further broadening its range of applications.

Role of chromium and nickel in 304 stainless steel

Chromium and nickel are the key elements that define the exceptional properties of 304 stainless steel. Chromium, typically present at about 18-20%, provides the alloy with its signature corrosion resistance by forming a thin, stable oxide layer on the surface that protects the steel from rust and environmental deterioration. Nickel, contributing approximately 8-10.5%, enhances the alloy’s ductility, toughness, and resistance to stress corrosion cracking. Together, these elements ensure that 304 stainless steel maintains its durability, formability, and strength across a wide range of applications, including kitchen equipment, medical devices, and architectural structures. Their synergistic effects also make 304 stainless steel highly versatile and reliable in both low and high-temperature environments.

Influence of other alloying elements on material properties

Beyond chromium and nickel, several other alloying elements in 304 stainless steel play vital roles in fine-tuning its properties. Manganese is added to improve the alloy’s hot workability and enhance resistance to wear and deformation, while also aiding in the stabilization of the austenitic structure. Silicon contributes to improved oxidation resistance, particularly in high-temperature environments, and bolsters the overall strength of the material. Carbon, while present in very small amounts, significantly influences the hardness and strength of the steel. However, excessive carbon can reduce corrosion resistance, which is why its content is carefully controlled. Nitrogen, though a minor addition, increases tensile strength and further stabilizes the austenitic microstructure. The calculated inclusion of these elements ensures that 304 stainless steel achieves an optimal balance of mechanical performance, corrosion resistance, and adaptability for various demanding applications.

References

Frequently Asked Questions (FAQ)

Q: What is 18-8 stainless steel and how does it relate to 304 grade?

A: 18-8 stainless steel is a type of stainless steel that contains approximately 18% chromium and 8% nickel. It is commonly associated with type 304 stainless steel, which is an austenitic stainless steel with similar composition. Understanding the density and properties of 18-8 stainless steel is crucial for its various applications in industry and everyday life.

Q: What are the key material properties or physical properties of 304 grade stainless steel?

A: The 304 grade stainless steel material properties include excellent corrosion resistance, high ductility, and good strength. Its physical properties include a density of approximately 8.0 g/cm³, a melting point of about 1400-1450°C, and a coefficient of thermal expansion of around 17.2 × 10^-6 /K. These properties make it a versatile material for various applications.

Q: How does the density of 304 stainless steel compare to other materials?

A: The density of 304 stainless steel is approximately 8.0 g/cm³, which is higher than that of carbon steel (about 7.85 g/cm³) but lower than some other stainless steel grades. This density contributes to its strength and durability while maintaining a relatively lightweight nature compared to denser metals.

Q: What are the main applications of 18-8 stainless steel?

A: 18-8 stainless steel, particularly the 304 grade, finds applications in various industries due to its properties and versatility. It is commonly used in kitchen equipment, food processing machinery, chemical containers, architectural and decorative metal products, and medical instruments. Its corrosion resistance and durability make it suitable for both indoor and outdoor applications.

Q: How do the mechanical properties of 304 stainless steel affect its performance?

A: The mechanical properties of 304 stainless steel, including its high tensile strength, good ductility, and excellent work hardening capability, contribute to its performance in various applications. These properties allow it to withstand stress and deformation while maintaining its structural integrity, making it suitable for use in demanding environments.

Q: What is the chemical composition and properties of 18-8 stainless steel?

A: The chemical composition of 18-8 stainless steel typically includes 18-20% chromium, 8-10.5% nickel, up to 0.08% carbon, and other trace elements. This composition gives it excellent corrosion resistance, non-magnetic properties (in annealed condition), and good formability. The high chromium content forms a protective oxide layer, enhancing its resistance to rust and staining.

Q: How does 18-8 stainless steel compare to 302 stainless steel in terms of properties and applications?

A: While both 18-8 (304) and 302 stainless steel are austenitic stainless steels with similar chromium and nickel content, 304 generally has slightly better corrosion resistance and lower carbon content. 304 is more widely used due to its superior weldability and slightly better mechanical properties. Both can be used in similar applications, but 304 is often preferred for more demanding environments.

Q: Why is understanding the density of stainless steel material important for its applications?

A: Understanding the density of stainless steel material is important because it affects the weight, strength-to-weight ratio, and overall performance of the final product. In applications where weight is a critical factor, such as in aerospace or automotive industries, knowing the density helps in material selection and design optimization. Additionally, density can impact heat transfer properties and is crucial in applications where thermal management is important.

Q: Are there any specific applications where the magnetic properties of 18-8 stainless steel are advantageous?

A: Yes, the non-magnetic properties of annealed 18-8 stainless steel make it valuable in applications where magnetic interference must be minimized. This includes use in electrical and electronic components, medical equipment like MRI machines, and scientific instruments. However, it’s important to note that cold working can induce some magnetism in 304 stainless steel, so the right stainless steel grade should be chosen based on the specific requirements of the application.