Leading Alloy Manufacturer in China

We manufacture various high-performance alloys. With advanced processing facilities and global steel partnerships, we offer top quality and tailored solutions.

Why Choose Us

Global Steel Partnerships

Authorized distributor for world-class steel mills, ensuring authentic material sourcing and price competitiveness.

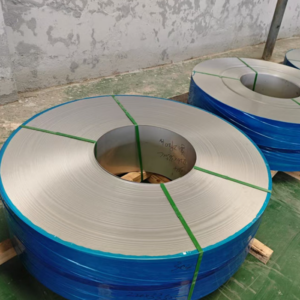

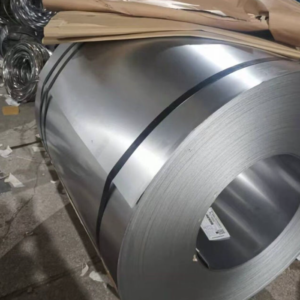

Advanced Processing Facility

Our facility features imported precision equipment including refining furnaces, hot-rolling machines, and water cutting systems for superior production.

Comprehensive Product Range

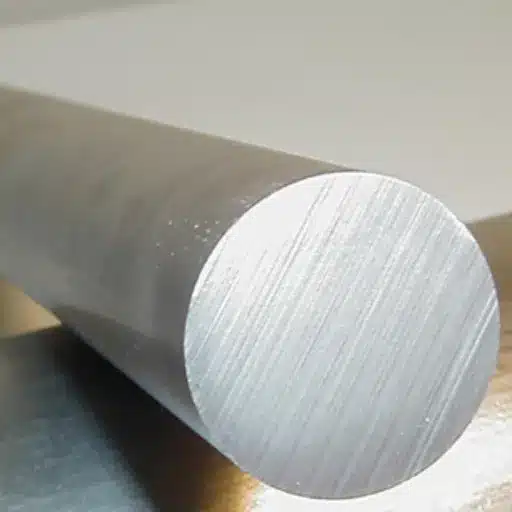

Extensive inventory of specialty alloys including Hastelloy, Inconel, and stainless steel series in plates, tubes, bars, and forgings.

Quality Assurance & Service

24/7 service with material certification, spectral verification, and custom logistics solutions for global shipping and delivery.

Product Category

Hot Products

Our Commitment to Quality

What Our Clients Say

Jiangsu Zhonggongte’s Hastelloy materials have consistently outperformed competitors in our chemical processing equipment. Their material certification is impeccable, and delivery has always been on schedule even during supply chain challenges.

Michael Rodriguez

Chem Tech Industries

We’ve sourced stainless steel 316L from various suppliers, but Zhonggongte’s quality control is exceptional. The consistency in composition and dimensional accuracy has significantly reduced our rejection rates in component manufacturing.

Sarah Chen

Precision Technologies

Their technical support team’s expertise in recommending the right alloy grades for our high-temperature applications has been invaluable. The Inconel 718 materials we purchased exceeded performance expectations in our testing facilities.

Rajiv Patel

Thermal Solutions Ltd

The custom-cut specialty alloy plates arrived with perfect dimensional accuracy. Their water cutting capabilities and edge quality are outstanding, saving us significant machining time and resources.

Anders Johansson

Engineering

Their ability to source rare specialty alloys with short lead times has been crucial for our oil and gas projects. Their global partnerships with premier steel mills ensure we get authentic materials with complete traceability.

Mohammed Al-Farsi

Gulf Energy Solutions

We appreciate their transparent communication and problem-solving approach. When we needed a specific grade of duplex stainless with unusual dimensions, they worked directly with the mill to fulfill our requirements.

Carlos Mendez

Oceanic Infrastructure Corp

Featured Articles & Guides

Frequently Asked Questions

We produce and distribute a wide range of specialty alloys including stainless steel (304, 316L, 321, 309S, 310S), Hastelloy (C-276, B-2, C-2000), nickel-based alloys (Inconel 625, 718), Incoloy (825, 800H), duplex stainless steel (2205, 2507), high-temperature alloys (GH4169), and copper-nickel alloys in various forms including plates, tubes, bars, profiles, and forgings.

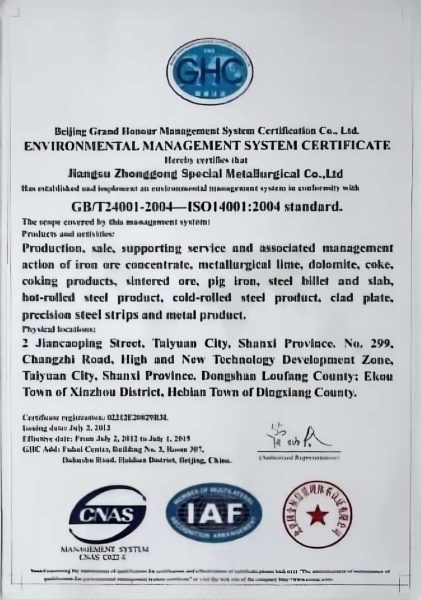

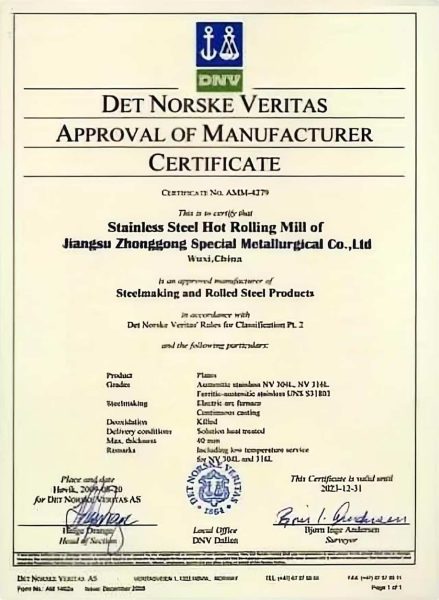

Our products comply with international standards including ASTM, ASME, EN, JIS, and GB. We provide full material certification with spectral verification, mill test reports, and detailed inspection certificates. Our manufacturing processes follow ISO 9001 quality management systems, and materials can be supplied with additional certifications like PED 2014/68/EU, NACE MR0175, and 3.2 certification upon request.

Minimum order quantities vary by product type, starting from 100kg for standard stainless steel to 500kg for specialty alloys. Standard inventory items can be shipped within 1-2 weeks, while custom orders typically require 4-6 weeks lead time depending on specifications and processing requirements. We offer expedited options for urgent requirements whenever possible.

Yes, our 168-mu processing center in Wuxi offers comprehensive custom services including precision cutting (water jet and plasma), slitting, leveling, polishing, beveling, and heat treatment. We can process materials according to your technical drawings and specifications, with tight tolerance control for demanding applications. Our facilities include imported precision equipment for superior finishing quality.

Absolutely. We specialize in corrosion-resistant alloys for aggressive environments, including chemical processing, offshore, and marine applications. Our high-temperature alloys maintain structural integrity and oxidation resistance at temperatures up to 1100°C, suitable for furnace components, heat exchangers, and petrochemical equipment. Our technical team can recommend optimal materials based on your specific operating conditions.

We provide worldwide shipping with comprehensive logistics solutions. Standard payment terms include T/T (30% deposit, 70% before shipment), L/C at sight, and D/P. For established customers, we offer flexible payment options. All shipments include proper packaging, material certification, and shipping documentation. We provide real-time tracking information and can arrange door-to-door delivery through our logistics partners.