Stainless Steel 308, known as UNS S30800, is a material that is used in many industries due to its good strength, corrosion resistance, and weldability. The blog aims to provide relevant information about 308 stainless steel, covering its properties, unique features, chemical components, pros, and applications in different industries. It also covers the in-depth aspects of welding this grade of stainless steel. The post is targeted at both professionals in need of detailed information and people who are interested in knowing more about the topic.

What is 308 Stainless Steel, and How Does it Compare to 304?

308 stainless steel is categorized as an austenitic stainless steel owing to its superb corrosion and weldability properties. Resembling 304 stainless steel, it has chromium and nickel as the major alloying components, however, it has a little greater nickel content along with other traces of manganese. 304 stainless steel is widely known for its versatility in various usages. At the same time, 308 is specially designed to improve welding processes as it reduces carbide precipitation during high-temperature operations. This renders 308 stainless steel particularly advantageous in welding processes where structural stability and corrosion resistance are crucial.

Understanding the composition of 308 stainless steel

The main constituent of 308 stainless steel is iron, which forms the base of the alloy. Other components include chromium in the 18-21% range and nickel between 9-12%. These alloys improve the oxidation resistance and enhance the strength of the alloy at elevated temperatures. The composition also contains minor amounts of silicon, manganese, and carbon. The steel’s preferred composition is purposely formulated to lower carbide precipitation while performing welds, guaranteeing the laid structure will survive harsh conditions. Therefore, the alloy is suited to applications that require great strength and high oxidizing environments.

Comparing 308 and 304 Stainless Steel Properties

Both 308 and 304 stainless steels qualify as austenitic stainless steels and have remarkable corrosion resistance; however, their compositions differ in the following ways.

- Chemical Composition:

308 Stainless Steel:

- Chromium (Cr): 19-21%

- Nickel (Ni): 9-11%

- Fe with traces of manganese, silicon, and carbon.

304 Stainless Steel:

- Chromium (Cr): 18-20%

- Nickel (Ni): 8-10.5%

- Other than the specified nickel and chromium, Fe has some balance trace germanium.

- Corrosion Resistance:

- Due to higher chromium and nickel content, 308 stainless steel has slightly better corrosion-resistant capabilities for specific environments. This increases its suitability for use where high temperature or chemically aggressive conditions are present.

- Weldability:

- 308 stainless steel is frequently employed as filler metal in welding 304 stainless steel. Its composition is tailored to minimize carbide precipitation during the welding process, thereby enhancing the durability of welded joints.

- While still providing good weldability, 304 stainless steel may require post-weld annealing in cases of high-stress corrosion cracking, which is a requirement of some applications.

- Applications:

308 Stainless Steel:

- Often used in welding filler materials and high-temperature applications.

304 Stainless Steel:

- Frequently used in less demanding applications such as kitchen appliances, automotive parts, and structural building.

These comparisons aid in choosing the right material for a particular scientific and environmental condition.

Key differences between 308 and 316 stainless steel

I believe that the main distinction concerning 308 and 316 stainless steel rests with their chemical makeup and compositional differences in corrosion. Molybdenum is present in 316 ss (in quantities of 2-3%), significantly improving hydrochloric acid and harsh chemical resistance. This makes 316 ideal in marine settings or industries requiring the handling of corrosive chemical substances. In the meantime, 308 stainless steel is mainly employed as a filler material in welding and temperature regions because of its fair degree of oxidation resistance. Still, it does not resist chloride as well as 316 does. He also uses it in construction, which adds another collision-resisting substance.

Technical Aspects:

Stainless Steel 308:

- Chromium: 19-21%

- Nickel: 9-11%

- Typical tensile strength: ~520MPa

- Uses: Welding rods, filler materials, works at high temperatures

Stainless Steel 316:

- Chromium: 16-18%

- Nickel: 10-14%

- Molybdenum: 2-3%

- Typical tensile strength: ~515 MPa

- Uses: Marine hardware, Pharmaceutical and chemical equipment, Medical parts

The first to pass acid tests is Chlorine. Climatic and performance terms determine the choice, and in places where acid resistance is a must, 316 should prevail.

What Are the Mechanical Properties of 308 Stainless Steel?

Stainless steel 308 combines strength, durability, and corrosion resistance. Its average tensile strength is approximately 620 MPa, and its yield strength is roughly 240 MPa. Its high chromium (19-21%) and nickel (9-11%) content allow it to have good oxidation resistance and weldability, allowing it to be used in fields such as welding wire production, structural parts manufacturing, and food equipment processing. Its chloride-induced corrosion resistance is slightly lower than 316’s.

Strength and ductility of grade 308 stainless steel

It pleases me to assist with the balance of strength and ductility of grade 308 stainless steel. The standardized composition of grade 308 stainless steel balances strength and ductility. Its tensile strength is about 620 MPa, ensuring the material can withstand significant force before breaking. The yield strength, close to 240 MPa, indicates plastic deformation before any fixed deformation occurs in the material. Moreover, it can be subjected to various degrees of forming without cracking, and it can be welding and structural parts and components, which highly industrial-grade ductility makes it possible to do so.

Impact of cold working on 308 stainless steel

The cold-working process incorporates strain-hardening, which significantly enhances the mechanical properties of 308 stainless steel. As a result, its deformation under stress becomes increasingly difficult due to increases in tensile and yield strength. As an illustration, depending on the amount of processing, tensile strength can improve from around 620 MPa to approximately 850 MPa, while the yield strength could improve from 240 MPa to about 450 MPa. Nonetheless, higher strength is associated with lower ductility, which means that the material has an impaired ability to be bent or stretched. Cold-working can also change magnetic characteristics due to the austenitic structure partially transforming to martensite. Notwithstanding these modifications, the stainless steel grade maintains its outstanding corrosion resistance and is appropriate for use where high strength and excellent durability are necessary.

Physical properties of UNS S30800

UNS S30800 is commonly known as 308 stainless steel. This material is known for its unique physical properties, which allow it to be used in various capacities. The materials have a melting density of approximately 8.03 g/cm³ and melt over 1400 to 1450 degrees Celsius. The material possesses excellent thermal conductivity measured at 16.3 W/m·K while exhibiting a coefficient of thermal expansion of 16.2 µm/m·K when heated from 20 degrees Celsius to 540 degrees Celsius. Furthermore, UNS S30800 has a modulus of elasticity at 193 GPa, making the material highly rigid while demonstrating stability under stress. Combined with corrosion resistance and mechanical performance, these properties make UNS S30800 Stainless Steel ideal in heat-intensive environments with significant mechanical loading.

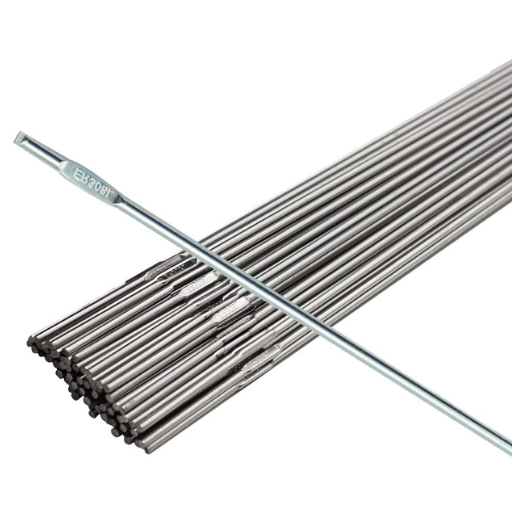

How Does 308 Stainless Steel Perform in Welding Applications?

Due to its excellent weldability and low risk of cracking, restricted 308 stainless steel is well suited for welding applications. The material is primarily used as a filler when joining other metals or stainless steel, especially the austenitic grades. Reduced low carbon content lowers the chances of carbide precipitation and decreases the chances of intergranular corrosion. Additionally, 308 stainless steel is reliable for use in industries that require durable welded joints as the material maintains good mechanical and corrosion-resistant properties even in welded joints.

Weldability of 308 Stainless Steel

As I have noted, 308 stainless steel is highly weldable and can easily be welded using various techniques, such as TIG, MIG, or stick welding. Its balanced composition minimizes the chances of cracking and intergranular corrosion, ensuring strong and durable weld joints. Furthermore, it has high-temperature stability, which is essential in demanding environments as it preserves the integrity of the welds.

Using 308 Filler Material for Welding 304 Stainless Steel

The use of 308 filler for welding 304 stainless steel is common because both materials possess compatible compositions, leading to strong and corrosion-resistant welds. 308 filler helps improve the weld strength due to its considerable chrome and nickel content, which complement 304 stainless steel. Moreover, it has a low carbon content below 0.08%, which helps minimize the chances of carbide precipitation and later intergranular corrosion.

Some of the technical details that require attention while welding are:

- Welding Technique: TIG (GTAW) and MIG (GMAW) are favored for their clean and precise welding capabilities.

- Shielding gas: Pure argon or argon-helium mix for TIG welds. Argon with CO2 (98% argon, 2% CO2) for MIG welding.

- Preheating: For 304 stainless steel, preheating isn’t needed unless the material is thick.

- Interpass temperature: Minimal movement or metal hardening if the temperature stays below 350F (175C).

- Post-Weld Treatment: This is mostly not needed and is done only if passivation is being used to improve corrosion resistance.

The 308 filler material guarantees the welds will remain with the mechanical and chemical properties of 304 stainless steel. This makes it ideal for use in food processing equipment and chemical environments, among other industries.

Preventing hot cracking in 308 stainless steel welds

Several aspects must be managed to mitigate the chances of the hot cracking phenomenon in the stainless steel 308 welds. i. For the prevention of excessive stress during weld joint solidification, proper joint design should be ensured as restrained cracking is likely to occur. ii. Maintain a steady arc without overheating the metal to control the heat input with specific parameters relevant to the welding. Using compatible filler material, such as 308 filler wire or 308L, is vital to preserve the metallurgical balance and control the sulfurous and phosphorous impurities that lead to cracking. Eliminate all contaminants on the base metal that would weaken the weld to ensure that the work area and base metal are clean. The final two parameters are controlling interpass temperatures and allowing sufficient cooling between passes which helps reduce the chances of hot cracking.

What Are the Corrosion Resistance Properties of 308 Stainless Steel?

The stainless steel 308 is widely used in construction industry due to its strong corrosion resistance, this is largely attributed to its high chromium and nickel grade. These elements introduce a protective layer of oxide that sits above the surface, which defends oxidation while suppressing the outcome of moisture, chemicals, and other corrosive shielding. It is commonly known to perform optimally with mild corrosion and moist atmospheres, often seen in food processing, chemical equipment, and aerospace components. Typically, however, it is not advised to use it in highly acidic conditions as it is prone to pitting and intracardiac corrosion. Proper use, such as regular maintenance, further improves its corrosion resistance.

Comparing the Corrosion Resistance of 308 to Other 300 Series Stainless Steels

The 300 series of stainless steel grades possess different levels of corrosion resistance, each uniquely based on its chemical makeup. Type 308 is a stainless steel grade that elbows fusible applications and other structural work. It has good corrosion resistance but not as good as the more specific grades of 316 and 304 in some environments.

- 304 Stainless Steel: Normally called the “18-8” standard stainless steel because of its 18% chromium and 8% nickel content, 304 has amazing corrosion resistance in many different conditions. Nonetheless, pitting and stress-corrosion cracking are possible under certain circumstances, especially in environments with high levels of chloride.

- 316 Stainless Steel: 316, on the other hand, is famously known for superior corrosion resistance, especially under harsh conditions. 316 stainless steel contains roughly 2-3% molybdenum, which further increases its resistance to chlorides, acids, and marine environments. This is why it is best suited for marine vessels, chemical handling, and even medical devices.

- 308 Stainless Steel: Grade 308 lacks certain resistance to chlorides and some acidic environments compared to 316. But 308 does possess good resistance to slightly corrosive conditions. The lack of molybdenum in grade 308 allows it to be more resistant than 304 in some oxidizing conditions, colder climates, and mild oxidation.

Technical Parameters

| Grade | Chromium (Cr) | Nickel (Ni) | Molybdenum (Mo) | Key Attributes |

|---|---|---|---|---|

| 304 | 18-20% | 8-10.5% | None | Good general corrosion resistance; prone to chloride pitting. |

| 308 | 19-21% | 9-11% | None | Robust for moderate applications; optimal as a filler metal. |

| 316 | 16-18% | 10-14% | 2-3% | Excellent in harsh environments, especially with chlorides. |

While 308 is a reliable choice for many applications, assessing environmental factors and specific use cases is important to select the optimal stainless steel grade.

Impact of higher chromium content on corrosion resistance

The self-reparable passive oxide layer and numerous forms of elemental environmental damage from corrosive stainless steel are sheltered by the higher chromium content in the stainless steel. From the many studies I have researched, stainless steel 316 works much more efficiently than 304 when exposed to calorific environments. The redundant layer also secures itself when damaged after enough chromium is supplied. It is known that the stainless steel grades with higher amounts of chromium, like 316, outperform other low chromium grades, especially 304, over prolonged periods. High amounts of chromium in stainless steel become necessary to enhance lifespan and resist corrosion over time.

Performance of 308 stainless steel in various environments

I have found that 308 stainless steel is usable in many environments but best suited for moderate corrosion conditions. Its oxidation and general corrosion resistance are good due to its chromium and nickel balance. It’s still not as strong against harsh conditions like high chloride or maritime environments as 316 stainless steel is because of its lower molybdenum content. Regardless, 308 excels in high-temperature environments, making it an ideal candidate for welding and structural applications where resistance to scaling and thermal endurance is critical. This material can expect adequate performance in many industrial environments, but in more severe environments, surface treatments or coatings may be needed to enhance durability.

How Does the Chemical Composition of 308 Stainless Steel Affect Its Characteristics?

Understanding the composition of 308 stainless steel helps gauge its capabilities related to distinct functionalities. Its composition of approximately 19 to 21% chromium and 9 to 11% nickel provides excellent resistance to corrosion, especially concerning oxidation and abrasion. Manganese and trace amounts of carbon also aid in improving the weldability and mechanical strength of the steel; hence, this grade of stainless steel is most commonly used in industrial and structural applications. The composition is optimum for moderate to high temperatures, providing resistance and durability.

Role of nickel and chromium in 308 stainless steel

The role of nickel and chromium in 308 stainless steel is crucial, as those elements aid in forming the primary characteristics of the steel. Chromium, present at 19 to 21%, forms a passive oxide at the surface of the steel, which protects it from corrosion due to various environmental factors. This passive film on the surface also provides higher resistance to oxidation at higher temperatures. Nickel, present at 9 to 11% in the composition, enhances the toughness and ductility while maintaining the austenitic structure. This mix increases and helps the alloy withstand thermal cycling, making the stainless steel ideal for industrial usage. These numbers provide an accurate measure that gives 308 stainless steel its durability in high heat and corrosion environments.

Influence of manganese on 308 stainless steel properties

Incorporating manganese in the alloying of 308 stainless steel is critical because of its impact. Manganese is part of the alloy complex in a 1 to 2 percent mixture, contributing to the 308 stainless steel hardness and strength due to solid solution strengthening. It also enhances the alloy’s abrasion resistance and neutralizes sulfur’s detrimental effect on steel. Moreover, manganese greatly enhances the deoxidization of the alloy during melting, providing a cleaner alloy with less residual impurities.

Looking at the technical parameters, the addition of manganese compounds enhances wear resistance and also aids in stabilizing the solidification of austenite along with nickel, which is needed to obtain desirable mechanical and thermal expansion characteristics. It also improves the alloy’s ability to withstand different operational conditions, further increasing the reliability of 308 stainless steel in corrosive and high temperatures.

Balanced composition for optimal performance

To the best of my knowledge, the balanced composition of 308 stainless steel aims to achieve good mechanical and corrosion-resistant properties. Manganese nickel and chromium are instrumental in retaining the austenitic structure, enabling the alloy to withstand high temperatures and corrosive environments. For a summary, here are reasonable technical parameters for the given average compositions:

- Chromium (Cr): 19.0-21.0% – Ensures strength and corrosion resistance.

- Nickel (Ni): 9.0-11.0% – Aids in ductility and Sustaining austenitic structure.

- Manganese (Mn): 2.0% max – Aids in deoxidation and wear resistance.

- Carbon (C): 0.08% max – Allows for strength and hardness without excessive brittleness.

- Silicon (Si): 1.0% max – Helps in protection against oxidation.

- Iron (Fe): Balance – The primary base metal.

In combination, these elements provide stability, performance, and reliability of 308 stainless steel in demanding applications expected of stainless steel.

What Are the Processing Characteristics of 308 Stainless Steel?

308 stainless steel is known for its outstanding weldability and formability, making it a great candidate for fabrication. Its low carbon content makes it ideal for welding because it reduces carbide precipitation and improves resistance to intergranular corrosion. Also, it is a good conductor of heat and remains tough over a wide range of temperatures. Employing tooling and methods designed specifically for stainless steel improves accuracy and reduces tool wear. These attributes make 308 stainless steel superlative for many industrial and structural applications.

Formability and Machinability of 308 Stainless Steel

308 stainless steel possesses exceptional formability for manufacturing complex shapes without cracking or reducing the material’s integrity. This is mainly due to its austenitic structure, high ductility, and cold work. It can be cold-worked to meet specific shapes and finishes, making it useful in numerous industrial processes.

Concerning material removal processes, 308 stainless steel needs special tools and processes to enable precision and minimize tool damage. It has a machinability rating of 45% of that of carbon steel, meaning low cutting velocities and high-standard cutting implements are needed for the best outcomes. For machining, the following guidance is recommended:

- Cutting speed: 50 to 80 fpm based on tool material.

- The feed rate of 0.004 to 0.012 inches per revolution is based on operation and tool shape.

- Coolant: sulfurized or chlorinated cutting fluid increases surface finish and assists with heat dissipation.

All these factors make 308 stainless steel ideal where accurate machining and the ability to form complicated shapes are required. Following these recommendations guarantees optimal efficiency in working with the material.

Heat treatment options for 308 stainless steel

Regarding heat treatment processes, my 308 stainless steel is well known for its resistance to alteration in microstructure. It cannot be hardened through heat treatment; rather, it is usually strengthened by cold working. The material should undergo heating in the range of 1900 – 2050 °F or 1038 – 1121 °C followed by rapid cooling or quenching by water to anneal the material. This treatment relieves stress and ensures the corrosion resistance is retained. Other means of stress relief can be conducted at low temperatures (around 800 to 1600 °F or 427 to 871 °C). Still, special attention must be paid to prevent sensitization, leading to corrosion resistance. In the broad strokes, the heat treatment processes for the 308 stainless steel aim to preserve the structural integrity and improve the mechanical configuration of the stainless steel.

Thermal properties and behavior during processing

The rationale behind my understanding is that their thermal properties are essential during material machining. The material’s properties, which I believe are very important, such as thermal conductivity, specific heat capacity, and the coefficient of thermal expansion, determine the material’s behavior to a change in temperature. For instance, metals have high thermal conductivity and, therefore, can absorb heat rapidly, causing the cooling or heating rate during manufacturing processes to be considerable. In contrast, ceramics have a low thermal conductivity and can retain heat for a long time.

Reasonable technical parameters are:

- Metals like aluminum or steel have a thermal conductivity of about 10-400 W/m·K.

- For polymers or metals, the specific heat capacity is around 0.5-1.5 J/g·K.

- CTE for ceramics and thermoplastics is 5-200µm/m·K.

Most of the aspects proposed are important for ensuring the system works adequately and addressing issues such as thermal stress or thermal distortion during processing.

References

- Stainless Steel – Grade 308 (UNS S30800) on AZoM – Provides detailed mechanical properties and grade 308 stainless steel characteristics.

- Stainless Steel Grade 308– Applications and Properties on Ambica Steels – Discusses the composition, applications, and properties of UNS S30800.

- 308 Stainless Steel (UNS S30800): Composition, Properties, and Uses on MachineMfg – Offers insights into the alloy’s composition and mechanical properties.

Frequently Asked Questions (FAQ)

Q: What is 308 stainless steel?

A: 308 stainless steel is an austenitic alloy with a balanced composition of chromium and nickel. It is similar to 304 but with a higher nickel content, making it preferred for welding applications due to its versatility and excellent corrosion resistance.

Q: How does 308 stainless steel compare to other grades like 304 and 316?

A: 308 stainless steel maintains a similar composition to 304 and 316 stainless steel but has a higher chromium and nickel content. This makes 308 more suitable for welding applications, as it provides better resistance to hot cracking and improved corrosion resistance compared to 304 stainless steel.

Q: What are the main applications of 308 stainless steel?

A: 308 stainless steel is generally used in welding applications, particularly for joining austenitic stainless steel. It’s commonly used to fabricate chemical processing equipment, food processing machinery, and other applications requiring excellent corrosion resistance and weldability.

Q: Why is 308 stainless steel preferred for welding applications?

A: 308 is preferred for welding applications due to its balanced composition, which helps reduce the risk of hot cracking during welding. Its higher nickel content also improves ductility and toughness in the weld, making it an excellent choice for joining austenitic stainless steels.

Q: Can 308 stainless steel be used to weld carbon steel?

A: 308 stainless steel is primarily designed for welding austenitic stainless steel, but it can also be used to weld carbon steel in specific applications. However, consulting with a welding or steel expert is essential to ensure proper material selection and welding procedures for particular projects.

Q: What type of welding rod should be used with 308 stainless steel?

A: For welding 308 stainless steel, it’s recommended to use AWS E308 or ER308 welding rods or wire. These consumables have a similar composition to the base metal, ensuring proper weld strength and corrosion resistance. Always consult welding specifications or a welding expert for specific project requirements.

Q: How does the corrosion resistance of 308 stainless steel compare to other grades?

A: 308 stainless steel provides excellent corrosion resistance due to its higher chromium and nickel content than 304 stainless steel. While it may not be as corrosion-resistant as 316 stainless steel in specific environments, 308 stainless steel is generally considered suitable for many corrosive applications, especially in welded structures.

Q: Is 308 stainless steel magnetic?

A: 308 stainless steel is generally non-magnetic in its annealed condition, as it is an austenitic stainless steel. However, some slight magnetic properties may develop after cold working or welding due to small amounts of martensite formation. This magnetism is typically minimal and does not significantly affect the material’s overall properties.