Nickel-based alloys are famous for their remarkable strength, resistance to corrosion, and flexibility, hence, they are used in various sectors, including, for example, aerospace and energy. Nevertheless, the same characteristics which make them essential can also create great difficulties in their efficient processing. The present article will explore the controlling of nickel alloys, the technical aspects, and the reasons behind their machinability and the methods to improve the process. You do not have to be a veteran in the field of machining nor an engineer who looks for better ways to increase production, this guide will give you an access to the entire wisdom and skills that are required to deal with these difficult materials.

Introduction to Nickel-Based Alloys

What Are Nickel-Based Alloys?

Nickel-based alloys are considered the best of all metallic materials, as they consist primarily of nickel, which is supplemented with chromium, molybdenum, iron, cobalt, and titanium in varying amounts. Their incredible resistance to heat, corrosion, and wear is the reason why they have been the first choice of many industries and applications. These alloys can operate in an extreme range of temperatures, even above 1,400°F (760°C), and they still possess strength and chemical stability.

New studies have indicated that the volume of nickel-based superalloy required for manufacturing jet engines will be approximately 50%. This shows that they play a significant role in the application of protecting the material from oxidation and creeping under high temperatures. Moreover, the use of these alloys goes beyond just gas turbines, medical implants, and chemical processing equipment, where corrosion resistance is the main property that ends up determining their longevity.

Nickel-Based Alloys Types

Nickel 200

Nickel 200 is a nickel alloy of nearly pure nickel with a 99.0% minimum nickel content. It is famous for its excellent mechanical properties and it also has good resistance to corrosion in alkaline environments. Additionally, this alloy is characterized by high thermal and electrical conductivity which makes it applicable in industries like electronic components, chemical processing, and aerospace engineering. Nickel 200 is also resistant to a variety of reducing agents such as, hydrochloric acid and hydrogen chloride gas, as well as sulfuric and hydrofluoric acids and remains functional from -320°F (-196°C) to600°F (315°C).

Nickel 201

Nickel 201 is a low-carbon version of Nickel 200 that enhances its use for high-temperature conditions. The lower the carbon content in the alloy, the lesser the chance of occurrence of intergranular corrosion and carbon precipitation, thus it can be used at temperatures of up to 1200°F (649°C) operating conditions. Nickel 201 is widely used in industries where its application involves the handling of caustic soda, the production of sodium hydroxide, and the manufacture of heat exchangers, as it is also resistant to corrosive heat.

Inconel Alloys (e.g. Inconel 625, 718)

Inconel, a family of nickel and chromium-based alloys, is renowned for its quality and ability to withstand the harshest environments, especially oxidation and high temperatures. For instance, Inconel 625 is perfect for marine, gas turbine, and even aviation engines because of its extreme strength and ability to resist the cracking caused by chloride-ion-induced stress. On the other hand, Inconel 718 is an aging alloy that is primarily chosen for its high strength and low-temperature weldability through the temperature range from cryogenic to elevated up to 1300°F (704°C).

Monel Alloys (e.g. Monel 400)

Monel alloys, particularly Monel 400, are a mix of nickel and copper, making the alloy highly resistant to seawater, acids, and alkalis. The application fields for Monel 400 cover marine constructions, chemical and hydrocarbon processing, and pumps and valves dealing with corrosive fluids, thanks to its features of excellent mechanical properties and ability to maintain strength and toughness from sub-zero up to about 1000°F (538°C).

Understanding Machinability of Nickel Alloys

Factors Influencing Machinability of Nickel Alloys

Material Composition

The chemical composition is one of the most important factors and also the main reason for the peculiar properties of nickel alloys: high strength, toughness and corrosion resistance. While these properties are advantageous, they also pose a challenge to machinery. For instance, metals with a high nickel content cause a very rapid wear-out of the tool due to the higher cutting forces and increased heat generated.

Generally, nickel alloys have low Thermal Conductivity, which leads heat to accumulate in the cutting area. If not controlled properly, this will make the tool lose its sharpness more quickly and result in defective surface finish. The use of cutting fluids and high-tech cooling systems are the traditional ways to lessen this effect.

Work Hardening

Nickel alloys show a lot of work hardening during the machining, thus the hard part is produced in the material that is cut. This hard region can give the operator more resistance, hence the cutting parameters must be set very precisely to avoid excessive wear or damage to the tool.

Cutting Speed and Feed Rate

Correct cutting speed and feed rate can make a major difference in optimizing the process. Research’s reveal that low-speed machining of nickel alloys will definitely help in prolonging tool life, however it also results in the opposite negative effect of surface roughness and imprecision when high feed rates are applied.

Comparison with Other Alloys

Nickel-based alloys like Inconel 718 and other materials have a very big difference when it comes to machinability. The main reason that nickel alloys are more difficult to machine than steels or aluminum is their high strength and thermal resistance. In this case, the machining of steel allows the usage of carbide tools with cutting speeds as high as 200 m/min, whereas for Inconel 718 the cutting speeds usually range from 30 to 50 m/min. This considerable difference is primarily due to the fact that the alloy does not lose its properties even at high temperatures.

In addition, aluminum alloys, which can easily be machined, up to 600-400 m/min can use carbide tools without quality degradation under the same conditions. The hardness of this alloy is lower, and its thermal conductivity is higher, both aspects which help chip removal and reduce tool wear.

Titanium alloys are also considered high-performance materials at par with nickel alloys. However, they are not a perfect match. The reactivity of titanium alloy surfaces with air and its comparatively low thermal conductivity lead to the formation of hot spots which contribute to tool wear. The cutting speed of carbide tools for titanium is typically between 20 and 60 m/min which is quite similar to that for nickel alloys but is influenced by similar advanced machining strategies like the use of high-pressure coolant and special tool coatings.

Challenges in Machining Nickel-Based Alloys

Tool Wear and Failure

Alloyed nickel materials are the ones that least wear out and so cannot be replaced easily in this world of machining. The major reason why this is the case is attributed to these materials’ inherent factors such as great strength, among others, accompanied by high melting point, and tendency to harden during working. In fact, all these factors put together will definitely give cutting tools a very tough time, making wear quicker and tool lives shorter. Besides heat and friction, some of the major causes of wear include crater, flank, and notch wear, and the presence of high temperatures and mechanical stresses during machining further aggravate these problems.

The manufacturers have recently reported that flank wear is the primary wearing mechanism during nickel alloy cutting and indeed one can observe measurable wear after a mere 15 to 20 minutes of continuous cutting at moderate feeding and speed settings. Research suggests that such cutting shall be done at speeds of over 50 m/min whereby the surface temperatures will be more than 1,000°C, and this will lead to thermal wear of both carbide and ceramic tools at a much faster rate. Notch wear is an event when the work-hardened layer just beneath the surface forms a high-stress zone that rapidly erodes the cutting edge of the tool.

Temperature Control and Stress Management

The cutting of nickel-based alloys generates a lot of heat and deformation thus heat and stress management in machining becomes the most important issue. The use of recent cooling technologies such as high-pressure and cryogenic machining helps to continue lowering the temperatures at the cutting zone. It is said that high-pressure coolant systems can decrease the cutting tool temperature by up to 50% thus providing improved surface finish and prolonged tool life at the same time.

Moreover, stress reduction methodology is the one concerned with cutting parameters in terms of feed rate, depth of cut, and cutting speed that are being optimized. It has been reported that reducing machining speed by 20-30% for the production of nickel-based alloys will lead to considerable stress concentration reduction making the tools last longer and the parts dimensional accuracy being higher. The use of Finite Element Analysis (FEA) is becoming a common practice in laboratories where digital simulations are made, and stress mapping is done to help the manufacturers to alter their machining processes for maximum performance.

Machining Methods for Nickel Alloys

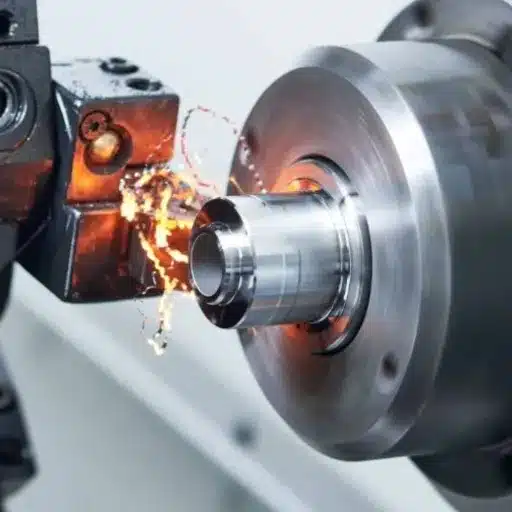

Turning Nickel Alloys

The nickel-based alloys are very strong and tough, which makes it necessary to employ special techniques to turn them around. The characteristics of the alloys not only lead to more tool wear which is similar to what happens with normal materials but also result in increased heat production at the same time and in the same place. The great turning process must still be accompanied by the production of suitable tools for the high-performance alloys, for example, using carbide or ceramic inserts with AlTiN or TiAlN coatings that are innovative in terms of heat resistance and wear protection.

Based on the analyzed data, the cutting speeds that are recommended for the turning of the nickel alloys generally range from 30 to 50 m/min dependent on the alloy and tooling material. The feed rates are often held at 0.1 to 0.3 mm per revolution in order to strike a balance between machining speed and the quality of the surface finish produced. Besides that, taking a cut of 1.0 to 3.0 mm can increase the rates at which material is taken off without overly stressing the cutter. The cooling systems that have the precision in the delivery of coolant also contribute to the dissipation of heat and the prevention of overheating that may affect both the tool and the workpiece.

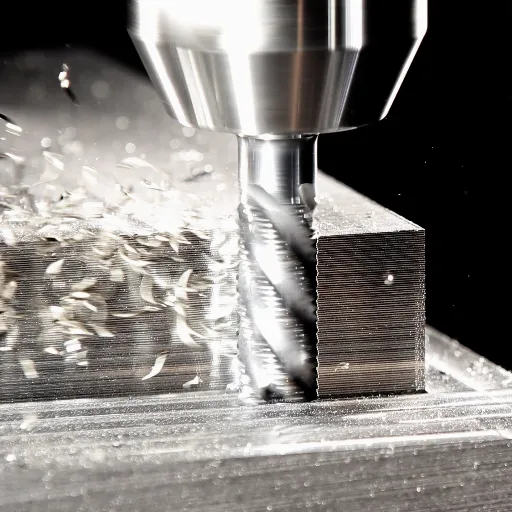

End Milling Techniques

Choice of Tool and Material

The choice of endmill is one of the crucial aspects that directly influence the outcome of machining operations. High-speed steel (HSS) and carbide tools are the most common materials used. Carbide end mills have become predominant in the market due to their superior hardness and temperature resistance, and thus cutting speeds of up to 250 meters per minute depending on the machining material can be set.

Feed and Speed Optimization

The latest control systems fitted in modern CNC machines allow for very precise adjustments of the cutting speeds and feed rates. Optimal feed rates for end milling are generally found to be between 0.05 to 0.5 mm per tooth, while spindle speeds can be set anywhere from 5,000 to 30,000 RPM, depending on the diameter of the tool and the material of the workpiece.

Axial and Radial Depth of Cut

To execute the material removal process thoroughly, the depth of cut must be correctly adjusted. The axial depth of cut (ADOC) is between 0.5 and 1.5 times the diameter of the tool for standard operations. Similarly, the radial depth of cut (RDOC) usually does not exceed 50% of the tool diameter to reduce the wear of the tool and to keep stability.

Advanced Cooling Techniques

Delivery methods like minimum quantity lubrication (MQL) and cryogenic cooling which are precision coolant delivery are becoming more and more accepted because of their quality in that they can practically and completely eliminate tool wear and heat distortion. The latest studies have shown that MQL usage can extend tool life by up to 45%, whereas the cryogenic treatment of the surface has been said to give the quality of the surface, especially when the material is hard to machine like titanium and nickel-based alloys.

Innovative Solutions in Nickel Alloy Machining

Advancements in Tool Materials

The extremely new and advanced tool materials have brought about a revolution in the machining of hard metals, for instance, nickel alloys. The hard metal cutting tools development is consisted of carbide and ceramic-based tools that not only last longer and support higher cutting speeds but also present higher cutting tools’ resistance to wear. Recent reports from industry sources suggest that carbide tools coated with cobalt and titanium carbide are experiencing hardness and heat resistance to the extent that a cutting speed between 30% and the old high-speed steel tools can be achieved.

Silicon nitride-based ceramics are getting widely accepted for metalworking in different fields such as aerospace and energy, where extremely high temperatures of 1,000°C (1,832°F), which is a very important factor in cutting super-heat-resistant alloys, are seen. Additionally, polycrystalline diamond (PCD) and cubic boron nitride (CBN) have been regarded as game-changers for ultra-precision manufacturing, resulting in up to 50% reduction in cutting tools wear during cutting.

Recent Manufacturing Technologies

The implementation of advanced manufacturing techniques is still under way in the process of reshaping the industry, directing it towards the more efficient, accurate, and environmentally-friendly production methods. One of these technologies is the very breakthrough of additive manufacturing, which is also called 3D printing. This technology is not only effective in producing intricate designs but also minimizes waste materials to the maximum since the material consumption is reduced by about 30% compared to that of the classic subtractive methods.

One can say that the most significant technological development has been linked to the emergence of Industry 4.0 powered by IoT, AI, and big data analytics. The smart factories are implementing real-time monitoring and predictive maintenance techniques, which have resulted in a 20% increase in equipment uptime and a 15% rise in productivity in their operations. For instance, IoT-based systems can even pinpoint when a part is going to fail, thereby eliminating expensive unplanned downtimes and, at the same time, facilitating the continuous flow of the production process.

Reference Sources

-

Data Bridge Market Research: This report highlights the global nickel alloy market, valued at USD 13.96 billion in 2024, and projected to reach USD 21.58 billion by 2032, growing at a CAGR of 5.59%. It provides insights into market trends and applications. Source link

-

Verified Market Research: This report provides an analysis of the nickel alloys market, valued at USD 14.81 billion in 2022 and projected to reach USD 23.78 billion by 2030, growing at a CAGR of 4.13%. It includes trends and market dynamics relevant to machining. Source link

Frequently Asked Questions (FAQs)

What is the effect of cutting fluid on nickel-based alloy machining?

Cutting fluid is considered to be the most significant factor in the processing of nickel and nickel alloys due to its ability to control and maintain the positive conditions that are required for the successful cutting process. The cooling effect of cutting fluid is the most important reason why it is so critical in this kind of metal cutting; however, it does also contribute to the functioning of curlers and breakers of chips by redepositing the chips during the process. Nickel alloys are considered to be the most difficult metal to machine, and one of the main reasons for that is that they tend to harden during the process.

What are the best practices for nickel and nickel alloy lathe machining?

With turning operations on a lathe, moderate or slow cutting speeds with high feed are recommended to ensure that positive chip formation takes place; climb milling is preferred for some features but can be less safe for the tough alloys. The Tools should be solid carbide or of high-speed steel with proper edge geometry and chip breaker to control curl and manage the chips. The cutting fluid should be applied continuously to control the temperatures during machining and thus to lower the risk of tool failure. For nickel 200 and Inconel X-750 and other heat-resistant super alloys, the rigid setup approach, light cuts to avoid chatter, and frequent checking of tool wear are the best practices.

What tools are best for processing nickel alloys and avoiding tool failure?

The most common tools for machining nickel-based alloys comprise solid carbide end mills with positive rake, carbide drills, and heavy-duty high-speed steel drills that are suitable for specific cast iron or wrought alloys. To avoid tool failure, it is good practice to use tough substrates combined with wear-resistant coatings, keep cutting edge geometry sharp, and apply chip breaker features to prevent the formation of long stringy chips. For alloys that are challenging to machine or when drilling deep holes, consider using stepped drilling and peck cycles and prioritize tool life through the correct cutting speeds and appropriate cutting fluid application.

What is the difficulty in machining nickel-copper and heat-resistant super alloys, and which alloys have similar challenges?

Nickel-copper alloys, group C and D alloys, and several heat-resistant super alloys are hard to machine due to the fact that they become harder and harder with the process, they have high strength even at high temperatures, and they conduct heat poorly. Aerospace and power generation industries are using such alloys. For instance, among the most commonly used are nickel 200 and Inconel X-750. The aforementioned material properties will generate very high cutting forces, very fast tool wear, and very high cutting temperature, at the same time, leading to the need for special tools and applying machining strategies to get the required amount of metal removal and surface finish.