It can be quite tough to cut stainless steel, but if you have the correct tools and know the right techniques, it will turn into a simple process. Do you need precise cutting and clean results? Then, it is necessary to know the best methods of cutting stainless steel whether it is a professional project or a mere DIY. This article will take you along the journey of the most efficient ways for cutting stainless steel discussing many different tools, methods, and tips that cater to various needs. You will get to know everything from power tools to manual techniques and how to pick the right one for your particular project. Get ready to be surprised at how this difficult material can be your ally!

Introduction to Stainless Steel

Properties of Stainless Steel

Steel that consists mainly of iron, carbon and chromium and also contains about 10.5%-30% chromium is considered a highly versatile and long-lasting alloy. The chromium responsible for anti-corrosion ability, thus benefiting the steel a lot, for when oxygen comes to the surface of the metal, a very thin but protective layer of oxide is formed. Additionally, the alloy may also have very small quantities of such other elements as nickel, molybdenum, or nitrogen depending on which property like strength, heat resistance, flexibility, etc.

The excellent durability of stainless steel is one of its most impressive characteristics. It has been known for its outstanding strength-to-weight ratio and thus is used in most areas where its wear and tear resistance and durability are almost equal to that of its great strength. The degree to which stainless steel can endure extreme temperatures differs from grade to grade but some types have even been made to operate effectively at 1500°F (800°C) and more. To be more precise, 316 stainless steel which is very resistant to marine and chemical environments, is even more so due to the presence of molybdenum.

Common Applications of Stainless Steel

1. Construction Industry

Stainless steel has huge impact on modern architecture and especially in structural work where its naturalness and resistance to sulphuric acid and alkaline are among the most decisive factors. The artistic side of things has seen buildings, bridges, and statues of futuristically styled material. Actually, stainless steel is a main factor not only in wall and roofing but also in other parts of buildings requiring very strong reinforcing bars.

2. Automotive Manufacturing

The automobile sector is going to replace aluminium with stainless steel for the exhaust systems, trims, and fuel tanks among other steel parts. The fact that the material is very high temperature and oxidation resistant, offers no doubt about its excellent quality for such applications. In addition, with the electric vehicle (EV) market growing, the need for stainless steel in the manufacturing of battery cases and parts rises as well.

3. Energy Sector

Stainless steel is the backbone of both generating and power generating infrastructure—be it from conventional or renewable sources. It is also the primary material used in the case of pipelines, heat exchangers, and storage tanks. The offshore oil and gas industry derives great benefit from the material’s ability to cope with extreme saline conditions. In addition, with the transition to green energy, stainless steel is becoming a part of wind and solar.

Best Ways to Cut Stainless Steel

Overview of Cutting Methods

⚡

Laser Cutting

The laser is a really efficient and super precise method of cutting stainless steel. The cutting method is done using pinpoint laser beams that make very neat and accurate cuts even for the most intricate designs. Usually, the cutting is done on sheets of stainless steel that have a thickness between 20 to 25 mm, which is thin to moderate. Industrial laser cutting machines are known for achieving such fine tolerances as +/- 0.1mm which makes them highly suitable for fields where precision is of utmost importance like in medical devices or aerospace components, for instance.

🔥

Plasma Cutting

Plasma cutting is a method that uses a stream of ionized gas to cut through the stainless steel. The process is very effective for the thickest stainless steel,. The thickness of stainless steel can be as much as 50 mm depending on the capacity of the plasma cutter. In contrast, the operation is to some extent less exact than the laser cutting but it serves the industrial sectors so well where the factors of speed and thickness of material to be cut become the most decisive.

💧

Water Jet Cutting

This cutting process is through a very powerful, high-pressure water jet carrying the resentful abrasive particles. So, the water jet cutting process is one with various capabilities; it is able to cut different thicknesses from the lightest sheets up to more than 100 mm. The very main advantage of the water jet cutting is that it does not produce heat during the cutting process thus there is no problem of distortion and heat-affected zones. As per the information provided by the manufacturers, waterjet machines can maintain the tolerances of +/- 0.003 inches which is one of the best in terms of precision.

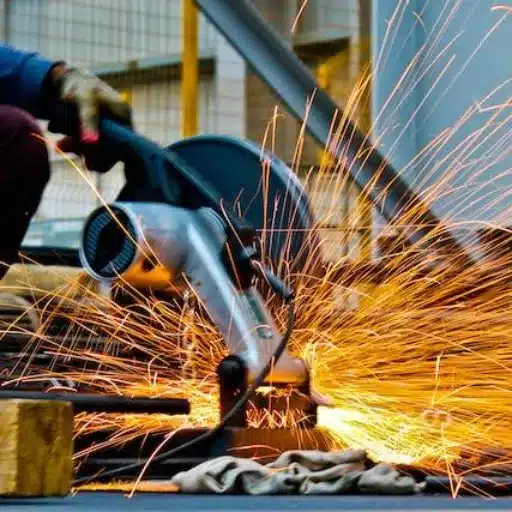

Using an Angle Grinder for Cutting

An angle grinder is a versatile handheld tool that is primarily used for cutting stainless steel but can also be used for cutting other materials. The small and portable design alongside the powerful motor make it perfect for both industrial and home use. When the correct disc, either an abrasive cut-off wheel or a diamond disc, is selected for the angle grinder, it can create cuts of stainless steel that are not only clean and accurate but also more demanding in terms of effort and skill than it would be to use CNC techniques or plasma cutting.

The proper handling of the grinder is a must for safety and accuracy if the angle grinder is to be utilized. Therefore, it is recommended that the first step be to attach the stainless steel piece to a bench or table using clamps to make sure it does not move during cutting. The disc should be positioned at a specific angle which is normally between 15 to 30 degrees so as to achieve a good cut. Using high-quality discs is said to cause less noise during cutting and greatly improved efficiency, according to the data.

Comparative Analysis of Cutting Techniques

Laser Cutting vs. Plasma Cutting

| Cutting Method | Description | Thickness Capacity |

|---|---|---|

| Laser Cutting | In laser cutting, a very powerful laser beam is applied that melts, burns or vaporizes the material. It is highly praised as a method of cutting for its precision and cleanliness, it makes even very tight tolerances cuts. Fiber and CO2 lasers are the most common types of lasers used for this application. Besides cutting the very same edges, laser cutting enhances intricate designs and allows diverse forms to be made. | Up to 0.4 inches (10 mm) |

| Plasma Cutting | In contrast, plasma cutting is a process that utilizes a high-speed flow of ionized gas (plasma) to slice stainless steel. It allows working with heavy sheets and easily cuts through the material. In case of thicker metals, plasma cutting is usually faster than laser cutting so it becomes the most popular choice for strict industrial applications. Overall, laser cutting is more expensive than plasma cutting in terms of both the initial investment and the running costs, thus, plasma cutting equipment is more suitable for workshops and sites with limited budgets. | Up to 1.5 inches (38 mm) |

Using Power Tools vs. Manual Tools

The decision to use power or manual tools primarily relies on the scope, scale, and specific requirements of a particular task. Power tools used in construction, for example, are powered by electricity, batteries, or compressed air. As a result, they are highly efficient, quick, and oriented to results which often makes them the answer for projects that are large or time-critical. A recent industry survey revealed that the utilization of state-of-the-art power tools in the process can lead to a reduction of 40% in project completion time as compared to manual tools.

Nonetheless, manual tools have precision and control as their strongest argument and do very well in small-scale or intricate works. To illustrate, a woodworker who specializes in fine details might prefer chisels over routers. Besides, manual tools are less expensive, do not require a power source and their maintenance costs are minimal, thus, making them suitable for beginners and small workshops financially. They may not be as quick as power tools but their reliability and user-friendliness are very much a requirement in certain situations.

Safety Precautions When Cutting Stainless Steel

Personal Protective Equipment (PPE) for Cutting Stainless Steel

Safety Goggles or Face Shields

The ANSI Z87.1 standard is the one that is referred to when it comes to safety goggles and face shields, and only those that match this standard are considered to be giving a sufficient level of protection and thus reducing the eye injury incidents. The greatest part of any operations involving the cutting of metal, particularly stainless steel, is that the eye is always protected against the hazards of the flying pieces and sparks.

Respiratory Protection

Chromium-containing particles are the most dangerous among the vapors released during the stainless steel cutting process, so NIOSH-approved masks like N95 are essential not only as a key part of the safety kit but also as a must-have. Long-term exposure to these poisonous materials has been associated with respiratory ailments, lung damage, and others.

Heat-Resistant Gloves

The cutting of the metal process can cause the steel to be very hot and if a worker has to handle such a piece, he or she is required to wear heat-resistant gloves for protective purposes. Leather, Kevlar, or other similar material gloves will provide not just heat resistance but also cut resistance and allow the worker to grip safely and securely.

Safe Handling of Tools and Materials

⚠️ Inspect Tools Regularly

It is vital that before tools are used they are always inspected for any defects or wear. A broken handle, a dull blade, or a faulty part can create a very risky situation during the operation. The American Society of Safety Professionals (ASSP) states that defective tools contribute to more than 10% of the annual injuries connected to tool usage.

💪 Use Proper Lifting Techniques

The right way should always be maintained when dealing with hefty materials, which means that the lift should be done with the legs instead of the back thus preventing any strain or injury. Use of improper lifting techniques even if it is slightly wrong results in musculoskeletal disorders (MSDs) which is one of the main reasons for health-related issues in the workplace.

📋 Follow Manufacturer Guidelines

It is imperative that safety and operational rules given by the manufacturers for both tools and materials be adhered to. This means using the right tool for the job and operating machinery only up to the specified limits. An instance of this would be cutting machine operation beyond the rated capacity leading to the risk of mechanical failure or accident.

Reference Sources

-

“Machining of austenitic stainless steels–a review”

- This review discusses optimal cutting conditions for austenitic stainless steels, including the use of cryogenic cooling for improved machining performance.

- Read the paper

-

“An optimization method of the machining parameters in high-speed machining of stainless steel using coated carbide tool for best surface finish”

- This study focuses on optimizing machining parameters for high-speed cutting of stainless steel, using coated carbide tools to achieve the best surface finish.

- Read the paper

-

“Machining of stainless steels”

- This resource provides a comprehensive overview of machining stainless steels, emphasizing the need for lower cutting speeds and appropriate conditions compared to carbon steels.

- Read the paper

Frequently Asked Questions (FAQs)

Shear, saw, or abrasive — what is the best method for cutting stainless steel sheets?

It all comes down to thickness and finish. A shear or bench shear produces fast, straight cuts in thin stainless-steel sheets with little heat. A band saw or metal-cutting circular saw with the appropriate blade for steel cutting performs well for medium-thicknesses while not compromising cut quality too much. Abrasive cutting (cut-off wheel or angle grinder) or a diamond saw blade can cut thick stainless steel quickly, but they also produce more heat and burrs.

What cutting tool should I use to get a neat cut from a stainless steel pipe — saw, cutter, or a tube cutter?

Using a tube cutter gives the most professional and cleanest cut on the thinner-walled stainless steel pipes. It will also help in avoiding deformation. The use of a band saw or circular saw with a stainless steel cutting blade (diamond blade or carbide-tipped blade) is recommended for the thicker-walled stainless steel pipes to cut through the thicker sections. The pipe should be clamped, the line marked, and the pipe should be supported so that no vibrations occur.

Can I cut stainless steel manually without having to use an electric saw? If yes, what manual cutter is the best?

Cutting of stainless steel can be done without the aid of power tools, but it is all contingent on the thickness. For sheets of thin stainless steel, a hacksaw fitted with a high-quality saw blade or a specialized manual shear could do the job. When it comes to cutting pipes and rods, the manual tube cutter or metal rotary cutter would be the most effective options.

What is the suitable blade and tpi (teeth per inch) for cutting metal with a circular saw?

The best blade for cutting metal sheet or steel plates with a circular saw is a thin kerf diamond blade or a carbide-tipped metal cutting blade designed for stainless steel. The higher the TPI (teeth per inch) the better the cut will be in terms of smoothness and straightness especially on thin materials; however, a lower TPI and a more aggressive tooth geometry can be better for thicker steel cutting but may increase burrs.

Ready to Start Cutting Stainless Steel?

Armed with the right knowledge, tools, and safety precautions, you’re now prepared to tackle your stainless steel cutting projects with confidence and precision.