Stainless steel bar stock serves as an essential material that supports multiple industrial sectors, which include construction, manufacturing, aerospace, and medical technology. The material provides high-strength properties that enable it to resist corrosion while maintaining its ability to perform in various applications across multiple industries. The industrial sector relies on stainless steel bar stock because it provides essential materials, while specific methods exist to determine which stainless steel grade meets your particular needs. The guide presents an in-depth study that examines all available stainless steel bar stock variants together with their multiple use cases and latest technological advancements that shape this sector. This article delivers essential information that helps readers understand how to choose materials while showing them the importance of stainless steel in contemporary technological applications and design practices.

Introduction to Stainless Steel Bar Stock

The Importance of Stainless Steel Bar as a Resource

The various industries use stainless steel bar stock because it offers both flexibility and durability, and protection against corrosion. Stainless steel maintains its structural strength through its special composition, which contains primarily iron, chromium, and nickel with additional alloying materials. The property provides particular advantages to the construction and automotive, aerospace, and medical equipment manufacturing industries, which need materials that will perform reliably for extended periods.

The worldwide stainless steel market has experienced growth, which experts predict will result in a market value of $182 billion by 2030 with a compound annual growth rate (CAGR) of 5.7% from 2021 to 2030. The upward trend exists because people want sustainable materials and because companies developed new stainless steel grades that provide better performance. The industry now widely uses duplex and super duplex stainless steels because they provide high strength and excellent environmental protection, which makes them suitable for offshore oil and gas equipment.

Manufacturers use stainless steel bars to create precise components because of their machining capabilities, which enable quick production of screws, fasteners, and shafts. Stainless steel bars provide an environmentally friendly solution because they can be recycled again and again without any loss of their original properties. The ongoing advancements, together with cutting-edge production technologies, make stainless steel bar stock essential for constructing future infrastructure and products.

Versatility of Stainless Steel Bar Products in Various Industries

The exceptional corrosion-resistant properties of stainless steel bar products, together with their outstanding strength and durability, make these products essential for various industrial applications. The construction and automotive manufacturing, medical device production and aerospace engineering fields depend on stainless steel bars as essential materials, which enable their technological development and reliable operational functions.

- Construction Industry: The construction industry depends on stainless steel bars as crucial elements, which provide structural strength to buildings and enable architects to design their contemporary structures. The worldwide stainless steel market reached a valuation of around $111.4 billion in 2022, according to current market research, with construction activities representing a major portion of that total. The high tensile strength of stainless steel bars, together with their ability to endure extreme weather conditions, makes these materials suitable for construction work on bridges and skyscrapers, and essential infrastructure projects. The material achieves cost-effectiveness through its extended lifespan, which requires minimal maintenance throughout its operational period.

- Automotive Sector: Automotive manufacturers depend on stainless steel because it serves multiple purposes while protecting their vehicle operators. Stainless steel bars function as vital components in exhaust system production and engine component creation because they maintain integrity at elevated temperatures while resisting corrosion. A recent analysis reveals that the shift toward electric vehicles (EVs) has further increased demand for stainless steel because EV manufacturers use the material to create battery enclosures and lightweight components that improve vehicle efficiency and safety.

- Medical and Healthcare Fields: The medical sector requires hospitals to maintain both hygienic conditions and sterile environments which stainless steel bars provide as essential materials used in producing surgical instruments and implants and hospital equipment. The increasing research focus on medical devices has created a growing requirement for biocompatible materials which stainless steel provides through its precise material makeup. The medical tools industry uses stainless steel 316L because it offers superior corrosion resistance and durability compared to alternative materials. The global medical equipment market which depends on stainless steel components, shows an estimated growth rate of 6.3% through 2030 according to recent data.

- Aerospace and Defense:The aerospace and defense sectors require materials that must meet their extreme performance standards which stainless steel bars successfully achieve. Aircraft landing gear and turbine components and fasteners use these materials because they provide excellent strength-to-weight ratios and thermal resistance. Defense budgets worldwide show increased funding which has been identified through market analysis while the aerospace industry has recovered from the pandemic which has led to higher stainless steel usage in critical applications.

- Food and Beverage Industry: Food processing companies and beverage producers depend on stainless steel because it does not react with products and its surface can be cleaned easily. Industrial facilities require strict hygiene standards which lead them to utilize stainless steel bars for their machinery and storage tanks and preparation surfaces. The food industry expansion leads to higher global demand for stainless steel products because consumers prefer food products that are processed safely and efficiently.

The diverse applications of stainless steel bar products establish their ability to provide exceptional adaptability across multiple operational functions. The development of new alloy compositions and production methods allows stainless steel to meet the modern industrial requirements of today while still serving as an essential material for current manufacturing needs and future applications.

Overview of Steel Bar Products and Their Uses

Stainless steel bar products serve multiple industries because they combine strength with corrosion resistance and long-lasting performance. The building and automotive and aerospace and healthcare industries increasingly use these materials because they need to comply with strict performance requirements and safety regulations. The construction industry needs stainless steel bars because they provide structural reinforcement that maintains integrity under extreme environmental conditions while protecting against rust and wear.

The stainless steel market will experience demand growth according to a recent market report which shows a compound annual growth rate (CAGR) of 5.2% between 2023 and 2030 because of new applications and infrastructure project funding. The global stainless steel market is estimated to reach $182 billion by 2030, signifying its expanding role worldwide. The development of alloy engineering has created new stainless steel forms which include duplex and super duplex stainless steel because these materials provide superior strength and chemical and high-temperature resistance which makes them essential for use in petrochemical and marine applications.

The healthcare industry also demonstrates how stainless steel bar products become important for producing surgical instruments and medical implants and pharmaceutical equipment, which need both cleanliness and exactness. Data shows a consistent increase in precision stainless steel bar production because of rising demand for medical-grade materials.

Stainless steel bars provide critical solutions for modern design challenges through their multiple applications which maintain their value across international markets.

Understanding Stainless Steel Bar Stock: Types and Grades

Different Types of Stainless Steel Bar Products

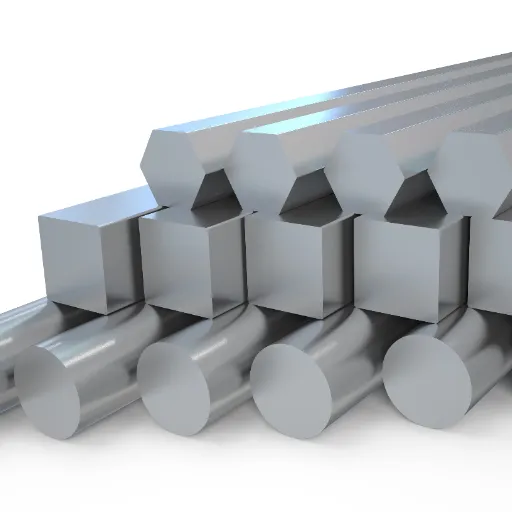

The industrial sector needs stainless steel bar products. The following section presents the primary stainless steel bar categories together with their distinctive attributes.

- Round Bars

The stainless steel round bar represents the most adaptable bar shape, which industrial and construction, and manufacturing industries widely utilize. The bars serve as essential materials for manufacturing machine parts and fasteners and equipment used in chemical processing. Recent market research shows that the global market for stainless steel round bars will experience a 4.2% compound annual growth rate because the automotive and construction industries increase their demand for the product. - Flat Bars

Stainless steel flat bars display a flat surface together with a rectangular cross-section which makes them suitable for structural use and brace construction and framework development and architectural design work. The renewable energy sector has adopted flat bars for use in wind turbine systems and solar panel mounting structures. Researchers have developed new materials that offer protection against corrosion damage in 316L grade materials which function effectively in extreme operating conditions. - Square Bars

Square bars provide special strength properties which manufacturers use to create decorative elements and gates and fences and custom machine components. Square stainless steel bars are preferred because they exhibit strong tensile characteristics, and they perform well in resisting deformation when stressed. The construction sector and general manufacturing sector show continuous growth in their need for these materials, according to market analysis. - Hexagonal Bars

Engineers commonly use hexagonal stainless steel bars to produce fasteners, bolts and nuts because their special shape prevents parts from slipping during assembly. Engineers use hex bars in their precision machining work because of the simple handling process and the consistent size of the bars. Industry insights highlight their increasing adoption in precision engineering and tooling. - Angle Bars

Stainless steel angle bars use their L-shaped cross-section to create frame structures and support systems and reinforcement materials. The equipment shows strong performance when exposed to heavy loads and severe weather conditions which makes it essential for outdoor industrial uses and architectural outdoor applications. Custom-sized angle bars have become the preferred choice for contemporary infrastructure projects, according to current market trends. - Channel Bars

Channel bars which engineers call C-section bars provide structural stability together with weight distribution capabilities. These bars find applications in bridge construction and rail track systems and equipment used in heavy industrial operations. Latest statistics reveal a growing preference for channel bars made from duplex stainless steel, which provides enhanced strength and corrosion properties.

The various types of stainless steel bars will experience increasing demand from different industries during upcoming years. Stainless steel functions as a vital material in contemporary engineering and design work because it delivers corrosion protection and strength and long-lasting performance. The new developments in alloy composition and manufacturing processes are establishing broader product applications, which enable stainless steel bars to meet the changing demands of international markets.

Comparing 304 and 316 Stainless Steel Bar Grades

The two most widely used stainless steel bar grades are 304 and 316 which each have different operational characteristics. Stainless steel exists in two grades which belong to the austenitic family that provides both exceptional corrosion protection and ease of shaping and durable strength. The different chemical makeup and operational features of both materials determine their industrial applications according to specific requirements.

- Chemical Composition

The primary difference between 304 and 316 stainless steel bars lies in their molybdenum content. The 316 grade contains 2-3 percent molybdenum which creates better corrosion resistance against chloride exposure and severe environmental conditions. The absence of molybdenum in 304 stainless steel results in reduced strength under extreme conditions while maintaining excellent adaptable performance. - Corrosion Resistance

The addition of molybdenum to 316 stainless steel bars provides better performance than 304 stainless steel bars when they face environments with strong saline water exposure and acid contact and industrial chemical exposure. The 316 alloy is used in marine, chemical processing, and medical applications which require protection against pitting and crevice corrosion. The 304 material provides dependable general-purpose protection against corrosion which makes it suitable for food processing operations and kitchen equipment and architectural design projects. - Strength and Durability

The two stainless steel grades 304 and 316 provide exceptional tensile strength combined with long-lasting durability. The mechanical properties of both materials show minimal distinction, but 316 provides better performance during extreme temperature and environmental conditions because it contains more alloying elements. - Cost Analysis

The presence of molybdenum and the improvement of material properties result in 316 stainless steel bars having higher production costs when compared to 304 stainless steel bars. The 304 material becomes the most cost-effective option for non-corrosive environments because it delivers satisfactory performance when used in projects that need to control expenses. - Applications at a Glance

- 304 Stainless Steel: Food service equipment, architectural frameworks, storage tanks, and automotive parts.

- 316 Stainless Steel: Marine fittings, medical implants, chemical tanks, and equipment used in harsh industrial processes.

The choice between 304 and 316 stainless steel bars ultimately depends on the specific requirements of the application, including environmental conditions, budget considerations, and performance needs. The industries will acquire better material decision-making capabilities through understanding these distinct characteristics.

Characteristics of Other Alloys: 303 Stainless Steel and More

303 Stainless Steel:

The design of 303 stainless steel specifically enhances machinability which makes it a perfect material for projects that need extensive machining work. The material achieves better machinability through sulfur addition which results in reduced corrosion protection when compared to 304 stainless steel. The material serves as an ideal solution for producing nuts bolts screws and precision machined parts. The chemical makeup of 303 stainless steel approximately contains the following elements:

- Iron (Fe): Balance

- Chromium (Cr): 17-19%

- Nickel (Ni): 8-10%

- Sulfur (S): 0.15% minimum

- Manganese (Mn): ≤ 2%

The material exhibits two principal characteristics, which include a tensile strength that ranges from 500 MPa to 750 MPa and a material density of 8.0 g/cm³. The material provides adequate protection against corrosion in most environments, yet falls short when used in marine environments and areas with chloride exposure.

Other Alloys:

- 430 Stainless Steel: The chromium-based alloy 430 stainless steel provides exceptional protection against corrosion while maintaining excellent joining capabilities. The material finds applications in kitchen appliances, automotive trims, and decorative elements. The material contains little nickel, which limits its capacity to withstand damage from acidic and marine environments.

- 17-4 PH Stainless Steel: The precipitation-hardened stainless steel 17-4 PH combines high strength with exceptional toughness. The material finds widespread usage in aerospace, chemical, and energy industries because of its strong mechanical properties and ability to resist stress corrosion cracking.

The evaluation of specific characteristics for every alloy enables industries to select materials that satisfy their performance requirements while staying within their financial limits.

Key Applications Across Industries

Common Applications of Stainless Steel Round Bar

The combination of strength, corrosion resistance, and machining ease of stainless steel round bars makes these bars useful in industrial applications that need these specific characteristics. The following list shows the primary uses of stainless steel round bars:

- Aerospace Industry

The aerospace sector heavily depends on stainless steel round bars, which include the 17-4 PH and 303 alloys as their main materials. These materials are used to create fasteners and landing gear components, and structural elements because they can endure intense pressure, high temperatures, and corrosive conditions. The aerospace demand for stainless steel round bars is expected to see growth, with the global aerospace market projected to grow at a CAGR of 6.5% from 2023 to 2030. - Automotive Industry

The automotive industry needs round bars for making vital components, including drive shafts and valves, fasteners, and exhaust systems. The exceptional durability of stainless steel, together with its corrosion resistance, makes it suitable for protection against both road hazards and environmental impacts. The use of stainless steel round bars enables manufacturers to create lightweight vehicle designs, which become crucial as the market demands higher fuel efficiency and lower emissions. - Construction Industry

Construction projects commonly use stainless steel round bars for their main functions of providing structural strength and supporting railings and building framework systems. The building material achieves longevity because of its capability to resist rust while enduring extreme weather conditions, which leads to decreased maintenance expenses. The worldwide demand for stainless steel material in construction projects increases because of the growing focus on sustainable building practices. - Medical Equipment Manufacturing

The primary material used to create medical instruments, which include surgical tools and orthopedic implants like bone screws and plates, consists of stainless steel round bars due to their biocompatibility and sterilization properties. Medical professionals use 316 and 304 grades because of their strong resistance to corrosion and their ability to maintain hygienic conditions. - Oil and Gas Industry

Stainless steel round bars function effectively in the severe conditions found within oil and gas operations. The piping system, valve components, and offshore platforms use these materials because they can withstand both stress corrosion cracking and pitting damage in saline and industrial environments. The rising global energy demand makes it essential to acquire high-performance materials like stainless steel. - Manufacturing and Machinery

The production process of machine tools, industrial equipment, and heavy machinery components depends on round bars as fundamental materials. The material properties of the product enable manufacturers to produce gears, shafts, and bearings. The product allows essential machinery to rely on its pressure capacity for dependable performance.

According to market studies, the stainless steel market achieved a value of $127.19 billion in 2022, and it will grow at a 6.2% CAGR until 2030. The increasing demand across these industries highlights the indispensable role of stainless steel round bars in modern manufacturing and infrastructure.

Uses of Stainless Steel Flat Bar in Construction and Manufacturing

The construction and manufacturing industries use stainless steel flat bars because these materials provide multiple benefits through their flexible use, long-lasting performance, and their ability to resist rusting. The building framework construction, support system development, and reinforcement element creation process depend on these flat bars as fundamental building blocks. The material is well-suited for use in bridges, industrial sites, and coastal facilities because it can endure severe environmental conditions that produce high humidity and extreme weather patterns.

Stainless steel flat bars serve an essential role in manufacturing because they create machine components, automotive parts, and precision instruments. The material possesses both malleability and strength, which enables designers to create custom products that fulfill their operational needs across multiple fields. Factory operations require these materials to manufacture conveyor belts and brackets, and fixtures, which they need to support their daily operations.

The 2023 industry reports indicate that stainless steel flat bars show rising demand because they contain information that supports this claim. The 2023 study found that construction companies worldwide used more than 40 percent of the total global stainless steel flat bar supply. The developed countries show increased infrastructure spending as they choose stainless steel flat bars because these materials deliver durable performance and economical long-term maintenance expenses. The global stainless steel flat bar market will grow at a compound annual growth rate (CAGR) of 5.8% during the period from 2023 to 2030 because these products have become essential for contemporary manufacturing methods and construction activities.

The combination of strong physical properties and increasing market demands establishes stainless steel flat bars as critical components for industrial operations in the present day.

Exploring the Role of Hex Bar and Square Bar in Engineering

The hex bars and square bars serve engineers as vital tools because these two primary bars create various engineering solutions and maintain high operational efficiency. The hex bars receive their name from their six-sided design, which enables users to handle them easily while they produce fasteners, machine components, and automotive parts. The assembly process requires special geometry components that distribute torque more effectively while decreasing assembly work slippage risks.

Square bars have solid four-sided shapes, which enable them to support construction and manufacturing operations by providing structural stability and load-bearing capabilities. Construction workers use square bars for making frames, braces, and railings, which are commonly made of stainless steel, aluminum, or carbon steel because these materials provide high strength and resistance to heavy pressure until failure.

The global hex bar market will experience steady growth between 2023 and 2030, according to recent market analyses, which show a CAGR of approximately 4.2% because athe erospace and, energy, and automotive industries show increasing product demand. The building and construction sectors drive strong demand for square bars because projects worldwide need steel reinforcement to achieve stability and reliability in their structures.

Material science advancements enable the creation of custom alloys that improve hex and square bar performance to meet modern engineering project requirements. Bars serve essential roles in maintaining structural integrity and supporting industrial functions, which makes them vital elements in the development of modern engineering techniques across different global markets.

Advantages of Using Stainless Steel Bar Stock

Corrosion Resistance: A Key Feature of Stainless Steel

The exceptional ability of stainless steel to resist corrosion makes it an optimal choice for various industrial uses. The protective function of the steel material develops because chromium materializes at 10.5% or higher, which creates a chromium oxide layer that protects the steel surface. The protective layer protects the material from oxidation and rusting, which occurs during extreme weather conditions.

The current research shows that stainless steel maintains its structural strength when subjected to acidic and alkaline substances, as well as environments with high chloride levels, which are typical in marine and coastal areas. The Type 316 stainless steel alloy contains additional molybdenum, which provides improved protection against pitting and crevice corrosion, thus enabling its use in saltwater environments. The research proves that this specific grade maintains its state throughout extended periods of saline exposure, which causes minimal signs of degradation.

Stainless steel’s corrosion resistance enables it to safeguard against environmental hazards that occur during both high and low temperature scenarios. Research indicates that certain high-performance materials, including duplex stainless steels, can sustain their structural integrity across a temperature range that extends from -50°F (-45°C) to more than 1,000°F (538°C).

The effective corrosion protection system decreases maintenance expenses for companies operating in construction, transportation, and chemical processing sectors, while it also enhances equipment durability and operational reliability. Engineers consider stainless steel to be an environmentally friendly and durable material, which requires little maintenance and prevents rust without needing additional coatings, in contrast to carbon steel.

Durability and Strength in Stainless Steel Bar Products

The combined durability and strength of stainless steel bar products create essential materials that various industries require for their diverse applications. The bars possess construction materials that enable them to withstand extreme mechanical stress and high temperatures, and corrosive environments, thus performing their functions in the most difficult conditions. Current research and industry information show that the tensile strength of stainless steel bars ranges from 515 to 1035 MPa, which depends on the alloy grade and manufacturing method. The material can withstand heavy loads without experiencing any deformation or material failure because of its high strength properties.

Stainless steel combines wear resistance with its ability to maintain mechanical functionality through various temperature changes. The 304 and 316 grades contain dual-use features that make them suitable for both cryogenic research and high-temperature industrial applications. The advanced manufacturing technique of heat treatment and cold working enables enhanced mechanical properties because it allows specific steel characteristics to fulfill particular application requirements.

The information shows that the long-lasting nature of stainless steel bars helps decrease costs throughout their entire lifespan. The materials maintenance costs are about 20-30% lower than carbon steel because of their resistance to corrosion and degradation, according to their average maintenance expenses. The particular advantages of these savings become crucial for industries such as construction, automotive, and oil and gas, which depend on extended operational efficiency together with dependable systems.

The implementation of stainless steel bar products in contemporary projects enables industries to achieve better strength-to-weight ratios while establishing new standards for environmentally friendly and economical engineering methods.

Cost-Effectiveness of Stainless Steel Bar Stock Over Time

The full value of stainless steel bar stock, which maintains its complete worth throughout its entire usage period, results from its exceptional material attributes and its ability to perform for an extended time. The upfront expense of stainless steel appears higher than that of other materials, yet its ability to resist corrosion and maintain structural integrity and its lower upkeep costs create value that offsets the initial expenditure.

Recent research shows that industries using stainless steel have achieved maintenance cost savings of up to 40 percent because stainless steel resists rust and deterioration better than steel. The material provides a typical lifespan of 50 years or more, which enables extended periods between replacements and results in decreased operational interruptions. Research demonstrates that stainless steel has versatile properties that enable 90 percent of its material to undergo recycling after its lifecycle ends, thus decreasing future costs for raw material acquisition.

The use of stainless rebar in construction projects for bridges and coastal areas produces 60 percent lower lifecycle expenses compared to traditional construction materials. The introduction of stainless steel components, which can endure harsh environments, enables automotive manufacturers to save billions of dollars on maintenance costs each year.

The sustainable operational advantages provided by stainless steel create an economically viable solution for all industries because it enables environmental protection through sustainable methods, which sustain operational strength and efficiency for current and future users.

Reference Sources

-

“The Case for Stainless Steel Reinforcing Bars”

- Key Findings: This study explores the use of stainless steel reinforcing bars in transportation infrastructure, focusing on their long-term durability and cost-effectiveness. It evaluates service life expectations of 100 to 300 years, emphasizing the material’s resistance to corrosion.

- Methodology: The research includes case studies and performance evaluations of stainless steel in various environmental conditions.

- Read more

-

“Product Development on Market Trends of Stainless Steel and Its Future Prospects”

- Key Findings: This paper discusses market trends and the standardization of stainless steel reinforcing bars in Japan. It highlights advancements in thermal efficiency and the adoption of new technologies to enhance product performance.

- Methodology: The study uses market analysis and experimental data to assess the impact of innovations in stainless steel production.

- Read more

Frequently Asked Questions (FAQs)

What is stainless steel bar stock, and what are its purposes?

Stainless steel bar stock consists of solid rods that exist in both circular and custom shapes made from stainless steel material. The bars come in different sizes, which include various diameter options and length options, and different alloy types to meet specific industrial needs. The construction and manufacturing industries use stainless steel bar stock because its corrosion resistance, strength, and durability make it suitable for making tools and fasteners, structural supports, and precision components.

What are the different types of stainless steel bar stock available?

The classification of stainless steel bar stock into different types occurs because its alloy composition and grade together determine its classification. The most common types include austenitic (e.g., 304 and 316), ferritic, duplex, and martensitic grades. The different variations provide distinct properties which enable their usage in various applications through their capacity to withstand either heat or corrosion, or stress. The stainless steel 304 grade stands out as a popular choice because it delivers superior performance across all applications, whereas the 316 grade serves as the better option for marine and chemical environments due to its extra molybdenum content.

How do industries benefit from stainless steel bar stock innovations?

The introduction of new stainless steel bar stock innovations has resulted in better operational performance and reduced expenses across multiple business sectors. The development of new alloy formulations enables materials to function effectively under extreme temperature and pressure and corrosive conditions. The combination of precision machining technologies with advanced surface treatments enables manufacturers to create components that exhibit improved durability and better performance at tighter production standards. The aerospace, automotive, and medical technology sectors have experienced significant advantages from these technological advancements.

What are the main benefits that stainless steel bar stock provides to modern manufacturing?

The usage of stainless steel bar stock in contemporary manufacturing delivers multiple benefits because it provides exceptional durability, protects against corrosion, and maintains high mechanical strength. The material serves a wide range of purposes, which include both structural applications and decorative applications. The sustainability goals of the organization align with stainless steel because it serves as an environmentally friendly material that can be recycled. This product becomes the preferred choice for manufacturers worldwide because its characteristics deliver cost savings while requiring minimal upkeep.

How does stainless steel bar stock support sustainability and cost efficiency?

The use of stainless steel bar stock creates both environmental benefits and financial advantages for businesses. The material allows scrap metal to be reused through its recycling process, which leads to substantial waste reduction during production. The extended lifespan of the product decreases both replacement requirements and maintenance expenses, which results in financial benefits throughout its entire operational period. Industries use stainless steel bar stock because its attributes help them achieve their environmental sustainability targets while maintaining their financial efficiency goals.

Can stainless steel bar stock be customized for specific applications?

The answer to this question is affirmative because industries can customize stainless steel bar stock according to their particular application requirements. The industrial sector needs particular material requirements, which include specific dimensions and surface finishes, and specific material grades. The manufacturing industry can now produce customized dimensions and designs through modern machining technologies, which include CNC precision cutting and advanced fabrication methods. The ability to customize stainless steel bar stock ensures that it meets the particular complex requirements of aerospace, architectural, and industrial engineering applications.