Get in touch with us

Leave a message

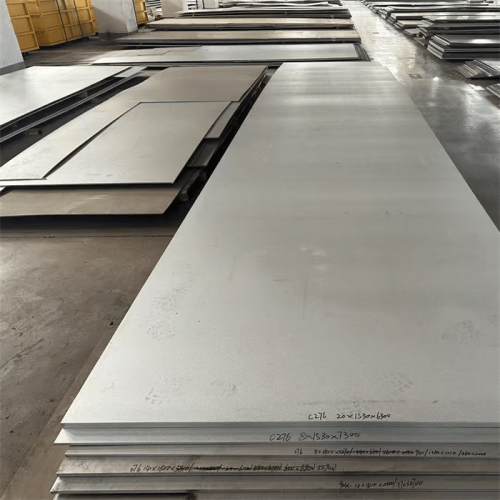

Our Hastelloy C276 Plates are available in various sizes and finishes to suit your project needs. Here are the standard specifications:

Find a Customized Hastelloy C276 Sheet version? We offer tailored solutions to meet your exact requirements.

These outstanding characteristics establish Hastelloy C276 Plates as the premier solution for demanding industrial environments.

The Hastelloy C276 Plate serves a wide range of industries:

| Element | Percentage (%) |

|---|---|

| Nickel (Ni) | 57.0 |

| Molybdenum (Mo) | 15.0 - 17.0 |

| Chromium (Cr) | 14.5 - 16.5 |

| Iron (Fe) | 4.0 - 7.0 |

| Tungsten (W) | 3.0 - 4.5 |

| Cobalt (Co) | ≤ 2.5 |

| Manganese (Mn) | ≤ 1.0 |

| Vanadium (V) | ≤ 0.35 |

| Silicon (Si) | ≤ 0.08 |

| Phosphorus (P) | ≤ 0.04 |

| Sulfur (S) | ≤ 0.03 |

| Carbon (C) | ≤ 0.01 |

| Property | Value |

|---|---|

| Tensile Strength | ≥ 790 MPa |

| Yield Strength | ≥ 355 MPa |

| Elongation | ≥ 40% |

| Hardness (Rockwell B) | ≤ 100 |

The Alloy C276 Plate resists a variety of aggressive chemicals:

Environmental Limits: Avoid prolonged use above 1900°F (1038°C) or in high-chloride conditions to maintain optimal performance.

While the C276 Hastelloy Metal is highly versatile, note these limitations:

| Environment | Corrosion Rate |

|---|---|

| Atmospheric | < 0.0025 mm/year |

| Mild Chemical | 0.0025 - 0.0076 mm/year |

Contact us for detailed corrosion resistance data specific to your application.

These traits enhance the usability of Hot Rolled Hastelloy C276 Plates.

We’ve relied on this China manufacturer for Hastelloy C276 Plates in our chemical plants. The quality and support are outstanding!

John D.

Chemical Engineer

The Hastelloy C276 Plates are perfect for our pharmaceutical setups. Corrosion resistance is superb!

Lisa M.

Pharmaceutical Supplier

These Hot Rolled Plates exceeded our expectations in high-temperature systems. Truly reliable!

Alex K.

Power Generation Specialist

A: Hastelloy C276 offers superior resistance to a broader spectrum of corrosive environments, particularly reducing chemicals and chloride-containing media. While C22 demonstrates exceptional performance against strong oxidizing agents and pure acids, making each alloy optimal for specific applications.

A: Yes, Hastelloy C276 exhibits excellent mechanical strength and structural stability at elevated temperatures up to 1050°C (1922°F). Its superior high-temperature properties make it ideal for heat exchangers, reaction vessels, and other high-temperature processing equipment.

A: Pricing varies based on dimensions, thickness, quantity, and current market conditions. Contact our technical team for a detailed quote tailored to your specific requirements and application needs.

A: While Hastelloy C276 offers good general corrosion resistance, it’s less recommended for direct seawater exposure due to potential localized pitting in high-chloride environments. Alternative alloys might be more suitable for marine applications.

A: GTAW (TIG) and GMAW (MIG) processes using matching Hastelloy C276 filler metals are highly recommended. Proper pre-weld cleaning and controlled heat input are essential to maintain the alloy’s corrosion resistance and mechanical properties.

A: Hastelloy C276 Plates are extensively used in chemical processing for reactors and storage tanks, pharmaceutical manufacturing equipment, pollution control systems, and oil & gas components. Their exceptional corrosion resistance makes them particularly valuable in environments involving aggressive chemicals and high temperatures.

Professional manufacturer of premium specialty alloys, offering stainless steel, Hastelloy, nickel-based alloys and processing services. Delivering superior metallurgical solutions for aerospace, petrochemical, marine engineering and other demanding industries.