Get in touch with us

Leave a message

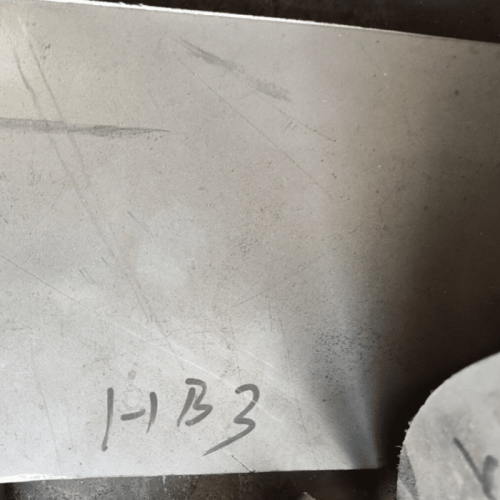

Curious about Hastelloy B3 Plate pricing? Contact our team for a custom quote. Costs vary by thickness, size, and order volume—reach out now for the best deal!

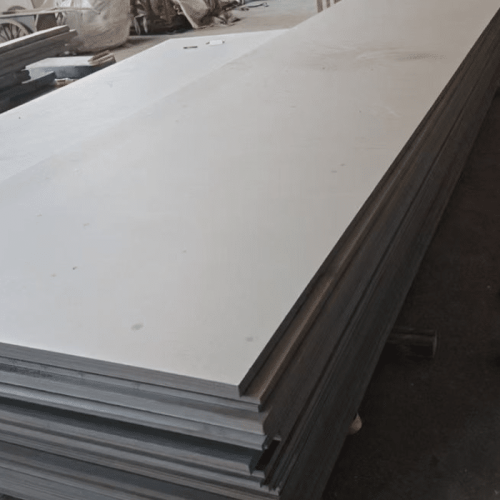

Here’s what defines Hastelloy B3 Sheet:

Our Hastelloy B3 suppliers ensure precision in every piece!

Why opt for Hastelloy B3 Sheet?

Hastelloy B3 Plate shines in demanding industries:

| Element | Symbol | Weight % |

|---|---|---|

| Nickel | Ni | Balance |

| Molybdenum | Mo | 27.0 - 32.0 |

| Chromium | Cr | 1.0 - 3.0 |

| Iron | Fe | 1.0 - 3.0 |

| Cobalt | Co | ≤ 3.0 |

| Manganese | Mn | ≤ 3.0 |

| Silicon | Si | ≤ 0.1 |

| Carbon | C | ≤ 0.01 |

| Phosphorus | P | ≤ 0.03 |

| Sulfur | S | ≤ 0.01 |

| Property | Units | Typical Value | Range |

|---|---|---|---|

| Tensile Strength | MPa | 860 | 760 - 965 |

| Yield Strength (0.2% Offset) | MPa | 400 | ≥ 350 |

| Elongation | % | 50 | ≥ 40 |

| Hardness (Brinell) | HB | 210 | ≤ 230 |

| Hardness (Rockwell B) | HRB | 95 | ≤ 100 |

| Modulus of Elasticity | GPa | 216 | 210 - 220 |

| Density | g/cm3 | 9.22 | 9.20 - 9.24 |

| Fatigue Strength | MPa | 350 | 300 - 400 |

| Shear Strength | MPa | 550 | 500 - 600 |

| Impact Toughness (Charpy V) | J (at 20°C) | 200 | ≥ 150 |

Hastelloy B3 Sheet resists various chemicals:

Avoid oxidizing environments like ferric or cupric salts.

Hastelloy B3 Sheet has some limits:

| Environment | Corrosion Rate (mm/year) | Resistance |

|---|---|---|

| Fresh Water | < 0.01 | Excellent |

| Salt Water (3.5% NaCl) | 0.1 - 0.5 | Moderate |

| Humid Air | < 0.02 | Excellent |

| Hydrochloric Acid (10%) | < 0.01 | Excellent |

| Sulfuric Acid (3%) | 0.05 - 0.1 | Good |

Contact us for detailed corrosion resistance data specific to your application.

Get the best from Hastelloy B3 Sheet:

Our Hastelloy B3 suppliers ensure top fabrication quality.

Elena K.

Vacuum Furnace Technician

Jake M.

Petrochemical Engineer

Sana P.

Pharmaceutical Equipment Designer

Professional manufacturer of premium specialty alloys, offering stainless steel, Hastelloy, nickel-based alloys and processing services. Delivering superior metallurgical solutions for aerospace, petrochemical, marine engineering and other demanding industries.

©2025 alloy-materials.com COPYRIGHT ALL RIGHT RESERVED.