As far as materials used in modern shipbuilding are concerned, AH36 steel is at the top of the list. This unique high-strength material is well known for its exceptional durability and versatility within the maritime industry. Whether it be used in gigantic container cargo ships, or the latest military naval vessels, AH36 steel is critical to maintaining safety, efficiency and structural integrity.

This guide will delve into the striking properties of AH36 steel, its key benefits pertaining to shipbuilding, and factors influencing its wide acceptance. It will also focus on the comparison with other steel variants, the specific parts of vessels that are made using it, and the criteria that are required for certification. Upon completion of this article, the readers will comprehend fully the reasons as to why AH36 steel is deemed a wonder in ship construction. It does not matter whether you are an engineer, shipbuilder or someone just keen to learn about maritime innovation, this guide is designed to help you appreciate the importance of this indispensable material in the industry.

What is AH36 steel and how is it used in shipbuilding?

AH36 steel is a high-strength, low-alloy structural steel grade that is specifically designed for use in shipbuilding. Its superior mechanical properties, including excellent tensile strength and toughness, make it ideal for withstanding the harsh environments encountered at sea. AH36 is primarily used in the construction of hulls, decks, and other key structural components of ships. It meets stringent certification standards to ensure durability, reliability, and safety in maritime applications, making it an essential material in modern shipbuilding.

Definition and classification of AH36 steel

AH36 steel is a high-strength structural steel grade primarily used in the shipbuilding industry. Classified under ASTM A131, AH36 is specifically designed for naval and marine applications. It is categorized as a low-alloy steel with superior mechanical properties, such as high tensile strength, toughness, and exceptional corrosion resistance. This steel grade is further classified as a “controlled-rolled” or “normalized” material, depending on its production process. Its classification ensures it complies with international maritime standards, allowing it to withstand environmental stresses such as impact forces, extended exposure to seawater, and extreme temperatures. These characteristics make AH36 one of the most trusted materials in constructing ship hulls, platforms, and offshore structures.

Key applications in shipbuilding and marine industries

AH36 steel plays a critical role in a wide range of marine applications due to its high strength, durability, and corrosion resistance. It is primarily used in the construction of ship hulls, where its robust mechanical properties ensure the vessel’s structural integrity under heavy loads and harsh ocean conditions. Additionally, AH36 is integral in crafting offshore platforms and structures, offering the strength needed to withstand high-pressure environments, such as deep-sea drilling rigs. This versatile material is also employed in fabricating components like bulkheads, deck panels, and superstructures, ensuring long-term reliability in both commercial and naval vessels. Its widespread use highlights its importance in delivering safety and performance across the shipbuilding and maritime sectors.

Advantages of using AH36 steel in ship construction

AH36 steel is renowned for its exceptional strength and durability, making it ideal for the demanding requirements of shipbuilding. Its high tensile strength allows vessels to endure harsh marine environments, ensuring structural integrity even under severe conditions. Additionally, AH36 steel is designed to be highly resistant to corrosion, a critical feature for materials exposed to saltwater and varying weather patterns. The material’s weldability enhances its practicality in construction, allowing for efficient assembly of components without compromising strength. Furthermore, AH36 steel’s versatility enables its use in critical parts like hulls, tanks, and offshore structures, contributing to the overall safety, longevity, and performance of marine vessels. Combining these benefits, AH36 steel ensures optimal reliability and cost-effectiveness in ship construction.

What are the mechanical properties of AH36 steel?

AH36 steel exhibits exceptional mechanical properties, making it a preferred choice in marine and offshore construction. It has a minimum yield strength of 355 MPa and a tensile strength ranging from 490 to 620 MPa, ensuring high resistance to deformation under stress. The material also offers excellent toughness, capable of withstanding low temperatures without significant loss of strength, which is critical for applications in harsh marine environments. These properties collectively contribute to the durability and safety of structures where AH36 steel is employed.

Tensile strength and yield strength of AH36

AH36 steel is widely recognized for its robust mechanical properties, particularly its tensile and yield strength. With a minimum yield strength of 355 MPa, AH36 ensures excellent resistance to permanent deformation under load. Additionally, its tensile strength ranges from 490 MPa to 620 MPa, highlighting the steel’s ability to withstand significant pulling forces before failing. These characteristics make AH36 an ideal material for shipbuilding and offshore structures, where strength and durability are paramount in demanding conditions. Its balance of high yield and tensile strength ensures reliability and safety for long-term use in harsh environments.

Toughness and impact resistance characteristics

AH36 steel exhibits excellent toughness and impact resistance, making it highly suited for applications in cold and harsh environments. Its inherent toughness ensures that the material can absorb significant energy during impacts or sudden loads without fracturing, which is crucial for maritime and offshore structures exposed to unpredictable forces. Furthermore, AH36 maintains these properties at low temperatures, thanks to its fine-grained structure and specific alloy composition. The material undergoes rigorous testing, including Charpy V-notch impact tests, to confirm its ability to withstand impacts under both standard and extreme conditions. These qualities contribute to the steel’s reliability and safety in demanding scenarios, reinforcing its reputation as a robust material for challenging applications.

Comparison with other shipbuilding steel grades

Shipbuilding steel grades are primarily categorized based on their mechanical properties, chemical composition, and suitability for specific maritime applications. When comparing with standard grades like A, B, D, and E, high-strength grades such as AH36, DH36, and EH36 offer greater tensile and yield strength, making them suitable for structures requiring enhanced durability and load-bearing capacity. Additionally, these higher grades excel in resisting impact and wear, especially in harsh marine environments, thanks to their controlled carbon and alloy content.

Compared to non-alloy grades, these high-performance steels often incorporate microalloys like niobium and titanium, which improve grain refinement and toughness while maintaining weldability. Unlike lower-grade steels, their ability to endure extreme conditions—like icy waters or heavy structural loads—sets them apart. For specific applications like Arctic vessel construction, specialized grades, including FH36 or even cryogenic steels, further excel in ensuring mechanical integrity at sub-zero temperatures.

Ultimately, the choice of grade depends on project requirements, with higher grades typically used for critical structural components or vessels operating in extreme weather conditions. Their balance of strength, toughness, and weldability ensures safety and longevity in a variety of maritime structures.

How does AH36 compare to EH36 and DH36 steel?

AH36, EH36, and DH36 are classified as high strength steels commonly used in shipbuilding and offshore structures. The focus of their differences is on the levels of toughness and the operational conditions of each grade. AH36 is meant for applications at room temperature, and has good strength and excellent structural integrity. On the other hand, DH36 has better strength in moderately cold temperatures, thus it can withstand somewhat tougher conditions. The level of toughness and durability seen with EH36 is higher, ensuring performance in extreme cold conditions. While all three grades have roughly the same strength, the differences in toughness create an array of specific environments and applications where they are most suitable.

Differences in chemical composition and processing

The primary difference in chemical composition between AH36, DH36, and EH36 lies in the varying levels of carbon, manganese, and microalloying elements such as aluminum, niobium, and vanadium. These adjustments are designed to improve toughness and resistance to environmental stress. AH36 generally contains slightly lower levels of alloying elements compared to DH36 and EH36, balancing strength with cost-effectiveness. DH36 and EH36 incorporate optimized chemical compositions to enhance resilience in colder or more demanding conditions.

From a processing standpoint, these steel grades undergo controlled rolling, quenching, and tempering to meet specific performance requirements. The heat treatment processes of DH36 and EH36 are particularly critical, ensuring enhanced grain structure for improved toughness and strength under stress. These distinctions in composition and processing ensure each grade fulfills the precise demands of shipbuilding and offshore engineering projects.

Strength and performance comparisons

When comparing the strength and performance of DH36 and EH36 steel grades, both materials demonstrate excellent mechanical properties suited for marine and offshore applications. DH36 steel is commonly utilized for shipbuilding due to its reliable tensile strength and good toughness, making it ideal for moderate to high-strength requirements. EH36, on the other hand, guarantees higher yield strength, improved stress resistance, and superior performance in extreme conditions, such as low temperatures.

The key difference lies in their structural role and environmental resilience. EH36, with its enhanced mechanical properties, is favored for critical structural components exposed to harsh marine environments, while DH36 serves efficiently in less demanding applications. Both materials conform to stringent classification society standards and are specifically designed to endure the rigorous demands of shipbuilding and offshore industries.

Specific use cases for each grade

EH36:

EH36 is predominantly used in high-stress applications within the shipbuilding and offshore industries. Its advanced mechanical properties and superior toughness make it ideal for crafting hull structures, offshore platforms, and large oil tankers. Additionally, EH36 is chosen for projects that require materials to endure cold temperatures and harsh marine environments, offering reliable performance under challenging conditions.

DH36:

DH36 is widely used in applications where strength and flexibility are necessary but without the extreme environmental demands faced by EH36. Common uses include structural components in small to medium-sized vessels, cargo ships, and support structures where moderate toughness is sufficient. DH36 is also cost-effective for general-purpose shipbuilding needs, maintaining reliability while balancing material requirements.

What is the chemical composition of AH36 steel?

Carbon, manganese, silicon, phosphorus, sulfur, and other elements make the chemical composition of AH36 steel. It usually consists of 0.18% carbon, 0.90-1.60% manganese, up to 0.50% silicon, and tiny traces of phosphorus and sulfur (usually not more than 0.035% each). All these elements work together to ensure that AH36 offers exceptional strength, durability, and enhanced performance for the demanding conditions of shipbuilding.

Key alloying elements in AH36

The key alloying elements in AH36 steel include carbon, manganese, silicon, phosphorus, and sulfur, each serving a distinct purpose in enhancing the material’s properties. Carbon, at approximately 0.18%, provides the necessary hardness and tensile strength. Manganese, ranging from 0.90% to 1.60%, greatly improves tensile strength and hardenability while aiding in the reduction of brittleness. Silicon, limited to a maximum of 0.50%, plays a crucial role in increasing strength and resistance to oxidation. Phosphorus and sulfur, typically kept below 0.035% each, are minimized to avoid weakening the steel or compromising its performance in harsh marine conditions. This careful balance of elements ensures AH36 steel’s reliability and resilience in structural applications, particularly in shipbuilding, where durability and strength are paramount.

Impact of composition on steel properties

The composition of steel directly influences its mechanical properties, durability, and performance across various applications. Elements like carbon significantly affect hardness, tensile strength, and wear resistance, though excessive amounts can reduce ductility. Manganese, often added as a deoxidizer, improves toughness and resistance to wear, while silicon enhances strength without sacrificing ductility. Microalloying elements such as vanadium and niobium refine grain structure, contributing to higher strength and improved toughness. Meanwhile, limiting impurities like sulfur and phosphorus reduces brittleness and enhances overall resilience. The precise balance of these elements allows steel grades, such as AH36, to be tailored for specific structural and environmental demands, illustrating how composition dictates functionality and versatility in engineering and construction.

ABS and ASTM standards for AH36 composition

Both the American Bureau of Shipping (ABS) and ASTM International set stringent guidelines to ensure AH36 steel meets high performance and safety standards. According to these standards, AH36 must maintain a carbon content typically not exceeding 0.18%, alongside a manganese range from approximately 0.90% to 1.60%. Additionally, trace amounts of other key elements such as silicon (up to 0.50%), phosphorus (maximum 0.035%), and sulfur (maximum 0.035%) are allowed, highlighting the importance of controlling impurities for durability and strength. AH36 is also required to achieve a minimum yield strength of 355 MPa and a tensile strength range of 490 to 620 MPa, ensuring reliability under high-stress conditions. These specifications are geared towards achieving consistency in structural applications, particularly in shipbuilding and offshore industries.

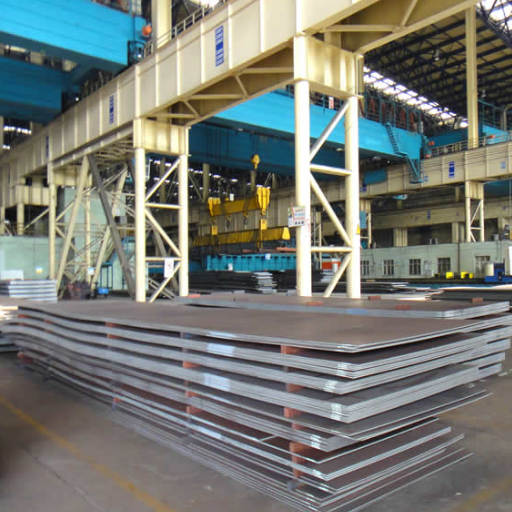

How is AH36 steel manufactured and processed?

AH36 steel is made by first melting raw materials in a blast furnace. These include iron ore, coke, and limestone. The steel is extracted and refined during its molten state to remove impurities and achieve the desired chemical composition. It is further processes by casting into slabs and refining through rolling and heat treatment. The mechanical properties of the steel, when subjected to processes such as rolling and heat treatment, enhance significantly with improved yield and tensile strength, meeting shipbuilding and offshore structures requirements. Finally, the steel is tested and controlled for quality to ensure all internationally set standards are met.

Production methods for AH36 steel plates

The methods used to make AH36 steel plates are focused on the requirements necessary for incorporation into marine and offshore applications. Firstly, the processes begin with the collection of raw materials, such as iron ore, coke, and limestone, which are put into a blast furnace for molten iron to be produced. This molten iron is then transformed into steel in a basic oxygen furnace where it is then oxidized to reduce carbon, sulfur, and other impurities. A series of refining steps called ladle metallurgy are also conducted to optimize the given steel for certain desired performance characteristics.

After the desired refinement of the steel is reached, it is cast into slabs to achieve its desired shape and is then hot-rolled to further the thickness of the plates as well as the microstructure. Various heat treatment techniques referred to as normalizing are applied to further the mechanical properties of the steel plates. These properties consist of, but are not limited to, toughness, weldability, and increased durability. Finally, the steel plates go through rigorous quality testing to ensure they meet the international classification standards set by abs, lr, and astm specifications. These techniques guarantee the production of steel plates capable of withstanding difficult marine conditions.

Heat treatment and controlled rolling techniques

Heat treatment and controlled rolling techniques are essential in refining the mechanical properties and structural integrity of AH36 steel plates. Heat treatment involves processes such as annealing, normalizing, and quenching, which alter the steel’s microstructure to improve weldability, toughness, and strength while relieving internal stress. Controlled rolling, on the other hand, is a thermomechanical process that carefully manages rolling temperatures to enhance grain refinement. This results in improved toughness and superior ductility, which are critical for marine applications. Together, these techniques optimize the plate’s performance in demanding environments, ensuring compliance with international standards and the resilience required in shipbuilding and offshore structures.

Quality control measures in AH36 production

Ensuring the quality of AH36 steel plates involves rigorous testing and adherence to strict industry standards. Key quality control measures include chemical composition analysis, tensile strength testing, and impact tests to certify compliance with specifications like ASTM A131. Ultrasonic testing is performed to detect internal flaws, while methods like X-ray inspection ensure weldability and homogeneity. Surface inspections are conducted to identify defects such as cracks or irregularities. These processes are complemented by precise temperature controls during production and post-production heat treatments to ensure optimal mechanical properties. Laboratories equipped with advanced testing facilities validate every batch, ensuring the plates meet structural integrity requirements for marine and offshore applications.

What are the welding considerations for AH36 steel?

Welding AH36 steel requires careful attention to maintain its structural integrity and mechanical properties. Preheating may be necessary for thicker sections to reduce the risk of cracking. Using low-hydrogen electrodes is recommended to minimize hydrogen-induced issues. Additionally, controlling interpass temperatures and employing proper post-weld heat treatments can further ensure weld quality. Strict adherence to welding procedures and standards is essential, particularly in marine and offshore applications, to achieve reliable and durable joints.

Recommended welding procedures for AH36

To achieve optimal weld quality for AH36 steel, several key procedures should be followed:

Preheating and Interpass Temperature Control

For thicker sections of AH36 steel (above 25mm), preheating to 50–120°C is recommended to reduce residual stresses and minimize the risk of cracking. Strictly control interpass temperatures within the range of 100–250°C to maintain the material’s mechanical properties.

Use of Low-Hydrogen Electrodes

Employ low-hydrogen electrodes such as E7018 or equivalent to prevent hydrogen-induced cracking. Proper storage and handling of electrodes are critical to minimize hydrogen contamination.

Welding Processes

AH36 steel supports multiple welding processes, including shielded metal arc welding (SMAW), gas metal arc welding (GMAW), submerged arc welding (SAW), and flux-cored arc welding (FCAW). Choose the method based on application requirements, equipment availability, and weld location.

Post-Weld Heat Treatment (PWHT)

Although PWHT is not always required, it is advised for critical applications to reduce residual stresses and ensure weld toughness. Specific conditions may vary based on project specifications.

Adhering to Standards and Procedures

Follow welding codes such as AWS D1.1 or ABS rules for steel vessels to ensure compliance and reliability in marine and offshore environments.

By implementing these procedures and adhering to accepted standards, welding AH36 steel can achieve the desired structural performance and durability.

Challenges in welding high-strength shipbuilding steel

Welding high-strength shipbuilding steel, such as AH36, presents several challenges that require careful consideration to ensure structural integrity and performance. One primary challenge is the risk of hydrogen-induced cracking due to hydrogen entrapment during the welding process. This issue is exacerbated by the high carbon content and alloying elements, which can increase the steel’s sensitivity to cracking.

Heat input management is another significant concern. Excessive heat can lead to softening of the heat-affected zone (HAZ), reducing the material’s strength, while insufficient heat input may result in poor fusion and incomplete penetration. Additionally, controlling distortion is critical, as welding high-strength steel can cause warping or uneven stress distribution, which compromises the structural alignment.

Environmental factors, such as moisture and temperature fluctuations, can also impact welding quality. Proper preheating, post-weld heat treatment, and the use of low-hydrogen electrodes are essential to mitigate these challenges. Strict adherence to welding codes and procedures further ensures the desired performance and long-term durability of the weld.

Best practices for ensuring weld integrity

To ensure weld integrity, adherence to several key practices is essential. Begin by thoroughly inspecting and preparing the base material, removing contaminants such as rust, grease, or paint to ensure proper fusion. Employing correct welding parameters—such as voltage, current, and travel speed—aligned with the material and intended application, is vital to achieving quality and durable welds.

Maintaining proper joint alignment and implementing gradual preheating, especially for high-strength steels, minimizes thermal stresses and reduces the risk of cracking. Selecting appropriate filler materials, such as low-hydrogen electrodes, further supports weld strength and decreases hydrogen-induced defects. Additionally, applying post-weld heat treatment helps relieve residual stresses and improves the overall toughness of the weld.

Lastly, consistent monitoring through non-destructive testing (NDT) techniques, such as ultrasonic inspection or radiography, ensures welds meet quality standards. Strict adherence to welding codes, routine equipment maintenance, and skilled operator training are also essential elements for achieving robust and reliable welds.

References

Frequently Asked Questions (FAQ)

Q: What is AH36 steel and why is it important in shipbuilding?

A: AH36 steel is a high-strength marine steel grade primarily used in the construction of shipbuilding steel plates. It provides excellent welding performance and durability, crucial for the safety and longevity of vessels.

Q: How does AH36 differ from EH36 steel plates?

A: The main difference between AH36 and EH36 steel plates lies in their mechanical properties. EH36 has higher strength and toughness compared to AH36, making it suitable for more demanding marine environments.

Q: What does the ‘ABS’ designation mean in ABS AH36?

A: ‘ABS’ stands for the American Bureau of Shipping, which sets standards for the classification and certification of marine equipment, including shipbuilding materials like ABS AH36, ensuring they meet safety and quality requirements.

Q: Can AH36 steel be used for offshore construction?

A: Yes, AH36 steel is suitable for offshore construction due to its high strength and excellent welding performance, making it ideal for harsh marine environments.

Q: What is the controlled rolling process and its significance in AH36 steel production?

A: The controlled rolling process is a method used in the production of AH36 steel to enhance its mechanical properties by carefully controlling the temperature and deformation during rolling. This process ensures better strength and toughness of the steel.

Q: Why is welding performance important for AH36 and EH36 steel plates?

A: Welding performance is crucial for AH36 and EH36 steel plates because they are used in shipbuilding, where strong and reliable welds are necessary to maintain the structural integrity of hulls and other critical components.

Q: How does BBN Ship Steel contribute to the production of AH36 steel?

A: BBN Ship Steel is a leading supplier and manufacturer specializing in providing high-quality AH36 steel plates. They utilize advanced production techniques, including micro-alloying technology, to ensure superior quality and performance in marine applications.

Q: What applications are mainly used for AH36 steel?

A: AH36 steel is mainly used in the construction of ship hulls, offshore platforms, and other marine structures due to its excellent strength, durability, and corrosion resistance.

Q: Is there a difference in using flat bar steel versus AH36 steel plates in shipbuilding?

A: Flat bar steel is often used for smaller structural parts and reinforcements, while AH36 steel plates are used for larger, load-bearing components in shipbuilding, providing higher strength and stability.

Q: How can I get more information or assistance about AH36 steel?

A: For more information or assistance on AH36 steel, you can contact us through our website or reach out to industry experts who specialize in marine and shipbuilding steel materials.