Yield strength plain carbon steel serves different stress levels while providing real-world value. That is where we delve towards providing comprehensive results under-discussed engineering applications. Yield strength can be explained in conjunction with any mechanical property, let alone with the microstructure of plain carbon steel. This means that such critical properties can further result from yield strength, allowing external factors to play their roles. Claiming such strength from carbon steel needs thorough details in return. This blog aims to cover explanations so that concepts can be easily understood in the simplest form possible. As over-ambitious as this blog structure might seem, it promises a clear outline of yield strength and its impact on dependencies on the performance reliability of plain carbon steel, especially in industrial and construction utilizations.

What is Plain Carbon Steel, and How Does it Differ from Other Steel Products?

Plain carbon steel is a type of steel whose essential components are iron and carbon, while traces of other alloying components are present. The carbon ranges from approximately 0.05% to 2.0%. It directly affects mechanical properties such as strength, hardness, and ductility. Chromis, nickel, and molybdenum are not present in proper quantities in plain carbon steel, unlike alloy steel, which goes with improved steel features like corrosion resistance or high strength at elevated temperatures. This additional component makes the alloy expensive and hard to work with. However, plain carbon steel is easier to work with, which makes it cheaper. This also makes it unsuitable for use when better-enhanced performance property is needed.

Characteristics of Plain Carbon Steel

I understand that plain carbon steel is mainly made of iron and carbon elements compared with other components in tiny percentages. The mechanical properties like laser cut and ductile cut elongation values depend on the carbon content, which is approximately between 0.05% and 2.0%. Strength and hardness improve with carbon content, which brings down ductility and weldability. Unlike alloy steels, plain carbon steel does not have valuable quantities of alloying elements such as chromium and nickel, making it cheaper and easier to produce. The lack of these features also makes them inexpensive advanced features such as corrosion resistance or high-temperature strength, making it difficult to function in demanding environments.

Comparison with Alloy Steel and Stainless Steel

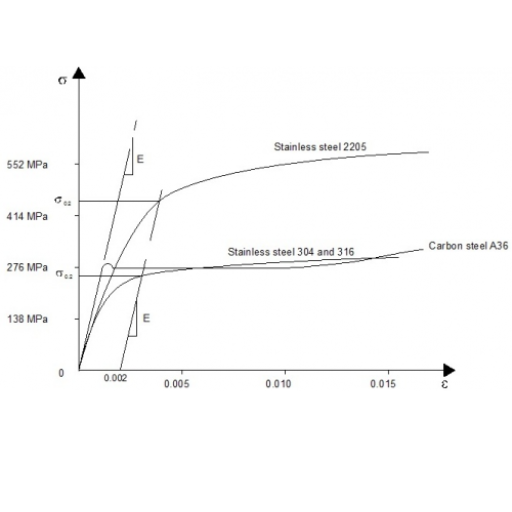

Due to their composition and performance, plain carbon steel, alloy steel, and stainless steel differ from each other and serve different purposes.

- Alloy Steel:

- Composition. Alloy steel consists of planned inclusions of alloying elements like chromium (Cr), nickel (Ni), molybdenum (Mo), and manganese (Mn) in varying quantities. These elements improve the steel’s mechanical and physical qualities.

- Technical Parameters. Depending on the alloying content and heat treatment, tensile strength typically lies between 600 MPa and over 2000 MPa. Specialized grades can exceed 60 HRC in hardness.

- Advantages. Strength, toughness, and wear resistance are improved. Certain alloys have good high-temperature stability and corrosion resistance.

- Limitations. Compared to plain carbon steel, fabrication is more complex and expensive.

- Stainless Steel.

- Composition. Stainless steel has a minimum weight percentage of 10.5% in chromium, which provides corrosion resistance by creating an oxide layer. Higher grades may include nickel, molybdenum, or nitrogen.

- Technical Parameters. Exceptional corrosion resistance and high-grade materials having pitting resistance equivalent numbers (PREN) over 40. Tensile strength ranges between 500 MPa and 1200 MPa.

- Advantages. Outstanding strength and aesthetic appeal, combined with resistance to rust and staining, make it ideal for architectural and medical applications.

- Limitations. Stainless steel is also significantly more expensive, weighing more than both plain carbon and most alloy steels.

Summary of Differences:

In terms of working carbon steel, plain carbon steel is the cheapest and easiest compared to other advanced options, such as structural supports. To illustrate, it lacks flexibility. On the other hand, alloy steel is more substantial and provides more flexibility, unlike wrought iron, which stubbornly fails to bend upon heating. At the same time, its distinguishing feature is enhanced strength and flexibility. Styl steel is also helpful in harsh and decorative regions due to its exceptional corrosion resistance. All of these features are suitable for mechanical and physical applications, but the selection of a material is determined by its specific needs.

Common Steel Grades and Their Uses

Like any material, specific mechanical features and usage greatly influence my selection of steel grades. For example, 1018 carbon steel grade is ideal for making various mechanical parts as it is highly weldable and easily machinable. It can also be utilized not only for low-strength shafts and steel parts but also in food processing and chemical equipment, especially parts that need corrosion resistance, as well as grade 4140 due to its exceptional durability and ability to withstand harsh conditions.

How Does Carbon Content Affect the Yield Strength of Steel?

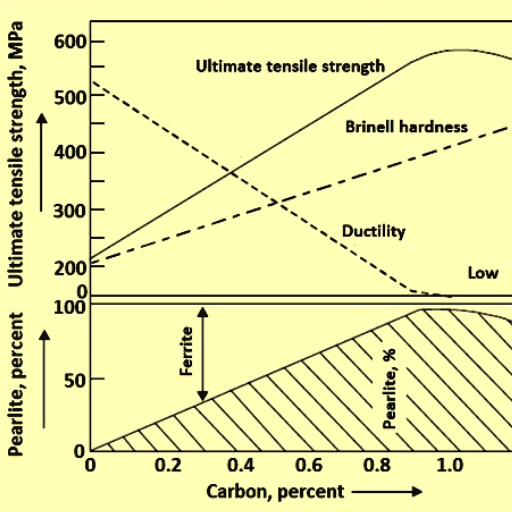

This is very important to note: the amount of carbon in steel is crucial as it dictates its yield strength. When the percentage of carbon increases, the microstructure of the steel gets progressively more carbon atoms. As more carbon atoms are present, the tensile strength and hardness increase. This subsequently results in better yield strength, which enables effective resistance to stress deformation. On the contrary, having higher carbon content can affect ductility and weldability, making it less ideal in specific environments. Thus, it’s a numbers game wherein the carbon content has to balance out to get desirable mechanical properties for a particular purpose.

Understanding Low-Carbon Steel vs High-Carbon Steel

Moving forward, the most crucial difference stems from the mechanical properties and carbon content. Low-carbon steel, which contains carbon below 0.25%, is well known for its marvelous ductility, malleability, and weldability. This is why it is commonly preferred in structural projects, automotive parts, and even pipelines, where flexibility and ease of fabrication are paramount.

High-carbon steel, in contrast, has a carbon content of roughly 0.6% to 1.0%. The presence of carbon in these amounts significantly increases the material’s hardness, tensile strength, and wear resistance. Parts made from these materials are used for cutting tools, springs, and other demanding applications such as high-strength wire. Ductility, the measure of how easily the material can be worked on, decreases, rendering it more brittle and less useful in welding or shaping processes.

In conclusion, low-carbon steel excels in the flexibility and ease of fabrication, whereas high-carbon steel provides improved durability, strength, and hardness but lacks flexibility and weldability.

The Role of Alloying Elements

The addition of other substances, known as Alloying elements, assists in modifying the properties of steel, enabling it to be used in a wide variety of industry sectors. Due to its concentration, an alloying element has specific effects when interacting with other components. These effects are mechanical, physical, and chemical.

- Carbon (C)

Carbon is the most crucial element that determines the hardness and strength of steel. Steel’s carbon content varies from 0.02% to 2.1%. If carbon content is increased, hardness and tensile strength improve, while ductility and weldability are negatively impacted. Low-carbon steels are more straightforward to machine and weld, while high-carbon steels have desirable wear resistance.

- Manganese (Mn)

Increases in manganese achieve increased hardness and strength, as well as increased wear resistance and steel deoxidization during steel production processes. Most grades of steel contain manganese between 0.3% and 2.0%. Too much manganese, however, can lower toughness.

- Chromium (Cr)

Chromium is an essential constituent of stainless steel. Its concentration is found to be above 10.5% to enhance corrosion resistance. Hardness and wearing resistance also contribute to the importance of tool steels and other high-strength applications. It is also critical for these metals.

- Nickel (Ni)

Nickel enhances toughness and strength and decreases corrosion, especially in cryogenic environments. The element’s weight percentage in structural steel typically ranges from 1.5% to 5%, whereas austenitic stainless steel contains more significant amounts.

- Molybdenum (Mo)

Molybdenum adds strength at elevated temperatures and increases pitting and crevice corrosion resistance. These metals are essential for steels that operate under very harsh environments and are usually found in amounts from 0.2% to 1.0%.

- Vanadium (V)

Vanadium promotes fine-grain structures and toughens steel simultaneously, thus increasing its strength. It is in minor proportions in structural and tool steels, generally in the 0.1% to 0.2% range.

- Silicon (Si)

Silicon dioxide strengthens steel without dramatically decreasing ductility. Its standard percentage range is 0.15 to 1.0.

- Boron (B)

Boron adds hardenability to steel but only in small percentages, usually under 0.003%. It is most commonly used in advanced high-strength steels (AHSS).

With these elements combined in specific proportions, steel can maintain completely different mechanical and chemical properties for maximum efficiency in construction, automotive, aerospace, and many other industries.

Impact on Material Properties

Looking at this in more detail, adding these alloying elements appears to change the material properties of the steel with significant control. For instance, carbon affects steel’s hardness and tensile strength, whereas manganese can improve ductility and impact resistance. Silicon serves the purpose of deoxidizing steel, helping to produce cleaner steel. Even oxygen, nitrogen, and trace elements like boron improve the hardenability of iron in small amounts. These components can be intentionally balanced to change steel grades to be more wear-resistant or easier to weld. These materials, therefore, become vital for use in precision-engineered parts.

What are the Mechanical Properties of Plain Carbon Steel?

This type of steel has different mechanical characteristics due to its carbon content and heat treatment processes. One important characteristic is the tensile strength, which improves as the carbon content increases. Another characteristic that changes is ductility, which decreases with increased carbon concentration. Moreover, hardness is another essential characteristic directly proportional to the percentage of carbon in the steel; it improves the wear resistance of the steel. In most cases, however, the carbon content tends to decrease the weldability of the steel. In addition, plain carbon steel has average toughness and brittle characteristics that may develop at higher carbon concentration levels. Due to these reasons, plain carbon steel is helpful in applications where a balance between strength and durability is required, but it has limitations that should be considered.

Exploring Tensile Strength and Yield Strength

Tensile strength is the maximum stress that can be tolerated by a material while being stretched or pulled. Qualitatively, for plain carbon steel, yield strength explains the stress level that begins plastic deformation, meaning that the material starts to deform permanently. Ductility in materials allows them to endure stresses without fracturing. As cited by specific experts, the tensile strength of plain carbon steels tends to go up, and so does the carbon content. More carbon content means more demanding and challenging material with more excellent resistance to any external force being applied. That, however, implies that ductility gets lowered. Yield strength also tends to be higher with more significant amounts of carbon. However, unlike the former, these values depend on factors such as quenching or tempering thermal treatments. It is essential to be aware of these features to ensure the appropriate balance in the chosen material for structures that will be load-bearing, reliable, and optimal over time.

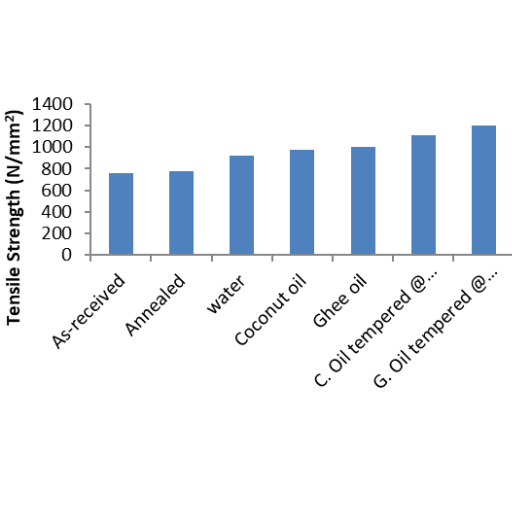

How Plain-Carbon Steel Balances Ductility and Strength

Fine-tuning the composition and heat treatment processes of plain carbon steel varies the mechanical properties to balance ductility and strength. The adjustment of carbon content typically bound to low-carbon steels between 0.05% and 0.25% or high-carbon steels up to 0.6%-1.00% is one of how the material’s mechanical properties can be adjusted. Other ways that increase the strength and the elongation capabilities include annealing, normalizing, and quenching, which alters the microstructures like ferrite, pearlite, or martensite, influencing the strength and elongation capabilities. For example, tempering after quenching helps restore ductility while lessening brittleness and maintaining adequate yield and tensile strength levels. The tensile strength (usually 400-1,300, varying untreated to treated and measured in MPa), yield strength (mostly 250-1,200 MPa), and elongation percentage (typically 5%-40%). The strength of the material acts as a support system for the flexibility and durability of the material, hence the strive towards value optimizations.

Comparison with Medium-Carbon-Steel

Medium-carbon steel has a lower percentage of carbon relative to high-carbon steel, typically ranging from 0.3% to 0.6%. With a blend of strength, ductility, and wear resistance, it effectively produces several parts like automotive components, structural parts, and railway tracks. Though it features lower tensile and yield strengths of around 500-800 MPa compared to high-carbon steel, medium-carbon steel has better machinability and weldability. The heat treatment process is focused on achieving an optimal balance between hardness and malleability, which often involves normalizing, annealing, or quenching with less aggressive tempering. This steel is also known to extend more when put under stress than high-carbon steel, allowing it to endure changes in shape without breaking. Through this, the steel demonstrates its usefulness in parts that require impact resistance and moderate flexibility. Choosing the correct type of steel is done considering load-bearing and wear factors, whereas medium-carbon steel does well if required for fine-tuned performance.

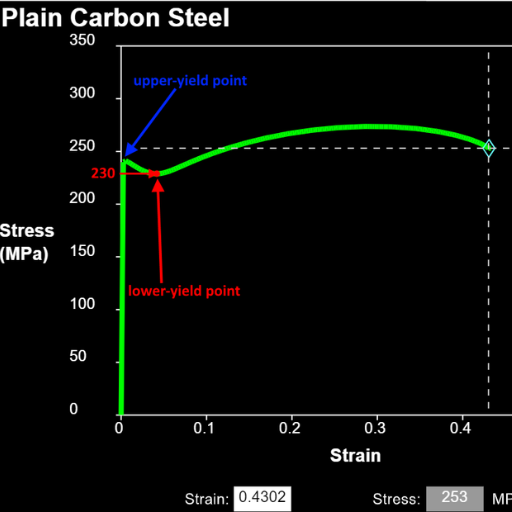

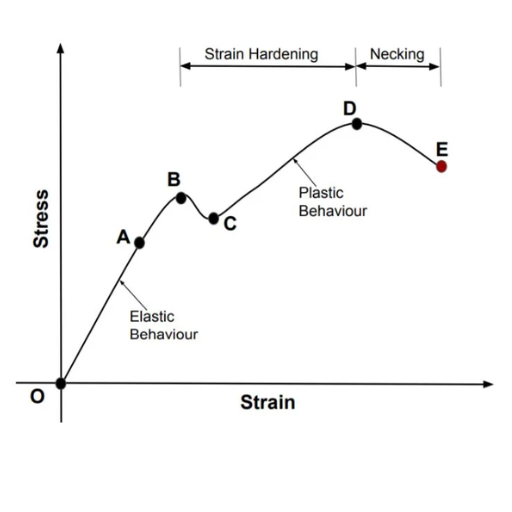

How is the Yield Strength of Plain Carbon Steel Measured?

The yield strength for plain carbon steel is identified through a tensile test. For this particular test, a sample is subjected to a mono-axial pull force until the sample begins to deform, such as plastic deformation. The test is done on a universal testing machine (UTM) that records the force applied versus the deformation (length) of the sample. From the stress-strain graph, the yield strength is measured and is usually captured at the transition region between elastic and plastic deformation. In offset or diversion, the average of 0.2% is used to capture yield strength for materials with no observable yield point.

Methods for Determining Yield Point

The yield point of plain carbon steel can be established through several methods, including analytical techniques. Some of these methods involve the following:

- Tensile Testing

As with other methods, tensile testing is the most direct method for determining the yield point. In this case, a specimen is held in place by a universal testing machine (UTM), which causes the specimen to undergo axial loading and elongation, which, in turn, is monitored. Slowly varying the length for the previously stated parameters provides a curve that can be plotted and illustrate the yield point where the transition between plastic deformation and linear elasticity exists. With plain carbon steel, the yield stress for that material is likely to be found in the region of 250 MPa to 400 MPa, depending on the grade and processing it went through.

- Offset Method (0.2%)

When materials don’t possess a well-defined yield point, like some traces of plain carbon steels that have continuous yielding, there is a widely accepted approach called the 0.2% offset technique. In this method, a line parallel to the elastic region of the stress-strain plot is drawn at an offset of 0.2 % of the yield strain, and the resultant stress is regarded as the yield strength for that offset. Confirming the values yielded through this method ensures standardized reporting measures.

- Extensometer Graphical Analysis

It’s valuable to have high-precision extensometers during tensile testing to check for even the slightest strain changes. Advanced cutting-edge systems enable software-aided accurate detection of yield events, obtaining very little human input. The yield point can be found through additional curve contouring/ regression analysis or plotted on a stress vs. strain graph. The software can also assess auto-detect yield events, minimizing human input.

In determining a material’s yield point, appropriate methods must be maintained, including sample preparation, gauge length selection, and error correction, as defined in the ASTM E8/E8M and ISO 6892 standards.

Importance of Ultimate Tensile Strength

Ultimate tensile strength (UTS) is necessary because now it can also be understood as the most significant number of stresses that can be put on the material in a stretched or pulled state before it fails. UTS is highly instrumental in ensuring accuracy for the selection of materials and in the design of engineering works so that all components and structures can sustain the necessary loads without losing their integrity. With UTS in mind, I know what functions can be done safely, avoid mechanical failures, and ensure the correct safety factors are allocated in construction, aerospace, and manufacturing.

Why Choose Plain Carbon Steel Over Other Types of Steel?

The absence of alloying elements in plain carbon steel makes it economical and more commercially available with a good range of mechanical properties. Its composition, essentially iron and carbon, reduces the production costs as it is cheaper to manufacture than alloy steels. Also, it possesses adequate strength, ductility, and machinability tailored to various applications, from structural parts to components of automobiles. Its easy predictability under normal operating conditions also adds to a designer or engineer’s reliability. However, its propensity to rust and lower strength in hotter climates and high temperatures are significant considerations when using this material in certain conditions.

The Cost-Effectiveness of Plain Carbon Steel

In selecting materials, I chose plain carbon steel because of its uncomplicated alloying constituents of iron and carbon that are strung together at low-level oils that lower production costs. Its abundant supply further drives down its procurement cost, making it attractive for larger projects. Moreover, it’s being recyclable adds to the savings in finances and the environment in the long run, making it a feasible choice for many cost-sensitive projects. Nonetheless, I factor in the moisture protective treatments required in highly corrosive environments, which can add to costs but often are reasonable given the price effectiveness of this material.

Common Applications and Steel Products

Regarding working parts, plain carbon steel is a popular material across various industries because of its effectiveness and broad versatility. Its uses reach construction and manufacturing areas where its mechanical control features work well under different conditions. For example, plain carbon steel is mainly used to produce structural parts like beams and columns due to the tensile strength, which is usually 400-550 MPa, depending on the grade. It is also used widely in manufacturing automotive parts such as body panels and frames, and its ductility (needed for processing isanging 10-25%) supports forming processes.

Moreover, these features are found in pipes, gas containers, and machine parts where maximum impact resistance and average abrasion resistance are essential. The thin, steel cold rolled sheets have a 0.5-3 mm thickness, which is typical for products with stringent surface quality requirements. For hot rolled products such as plates and bars, measured dimensions have an enormous range, with typical thicknesses of 6-100 mm depending on the design. These values demonstrate how the manufacturer’s standards for plain carbon steel fully meet the requirements of the practical application of industry standards.

Balancing Acceptable Material Properties

Achieving favorable input material properties comes from a thorough analysis of interrelated criteria such as strength, ductility, thermal resistance, and cost factor. For any application, I first identify the materials to construct the non-functional mass while maximizing the structure’s performance. For example:

- Tensile Strength: From 300 MPa to 2000 MPa, the definitives depend on materials such as metals and polymers.

- Elastic Modulus: About 200 GPa for steel and between 1 GPa and 5 GPa for polymers.

- Thermal Conductivity: Depending on application, for aluminum, 200 W/m·K, and for insulative polymers, 0.1 W/m·K.

- Cost-efficiency: This varies greatly, but materials are usually needed to be between the two extremes of weakness and strength.

With these values, the material’s performance is met within the set boundaries in structure, environmental conditions, and finances.

References

- Relationship between microstructure and yield strength for plain carbon steel with ultrafine or fine (ferrite+ cementite) structure – This article discusses the relationship between microstructure and yield strength in plain carbon steel.

- Ultrasonic prediction of grain size, strength, and toughness in plain carbon steel – This book provides insights into predicting yield strength and other properties using ultrasonic methods.

- Effect of carbon content on the plastic flow of plain carbon steel at elevated temperatures – This study explores how carbon content affects the mechanical properties of plain carbon steel.

Frequently Asked Questions (FAQ)

Q: What is the yield strength of plain carbon steel?

A: The yield strength of plain carbon steel varies depending on the percentage of carbon content. Low-carbon steel, which is a common form of steel, typically has a yield strength ranging from 250 to 400 MPa. Medium-carbon steel and high-carbon steel have higher yield strengths due to their increased carbon content.

Q: How does the percentage of carbon affect the properties of carbon steel?

A: The percentage of carbon in carbon steel significantly affects its properties. Low-carbon steel contains approximately 0.05% to 0.25% carbon, making it ductile and malleable. Medium carbon steel typically contains 0.25% to 0.60% carbon, balancing strength and ductility. High-carbon steel, with 0.60% to 1.25% carbon, offers higher strength and hardness but is less ductile.

Q: Why is mild steel considered a popular choice among different types of steel?

A: Mild steel, a form of low-carbon steel, is popular because its price is relatively low, and it provides adequate material properties for many applications. It is easy to work with, weldable, and offers a good balance of strength and ductility, making it acceptable for many applications.

Q: What are the characteristics of high-carbon steel?

A: High-carbon steel contains a high percentage of carbon, typically between 0.60% and 1.25%. This form of steel provides higher strength and hardness but is less ductile than low-carbon and medium-carbon steels. It is often used in applications requiring high strength and wear resistance.

Q: How does the tensile strength relate to the yield strength of carbon steel?

A: Tensile strength is the maximum stress a material can withstand when stretched or pulled before breaking. Carbon steel’s tensile strength is usually higher than the yield strength. The yield strength indicates the stress level at which a material begins to deform plastically, whereas tensile strength is the point at which it ultimately fails.

Q: What makes low-carbon steel an acceptable choice for many applications?

A: Low-carbon steel is an acceptable choice for many applications due to its ductility, weldability, and relatively low price. It is also easy to form and shape, making it suitable for structural applications, machinery parts, and automotive components.

Q: How do the properties of carbon steel vary with its form?

A: Carbon steel’s properties vary with its form, primarily due to the percentage of carbon content. Low carbon steel is softer and more ductile, while medium carbon steel offers a balance of strength and ductility. High carbon steel provides higher strength and hardness but reduced ductility. Each form of steel is chosen based on the required strength, hardness, and ductility for specific applications.

Q: What is the impact of carbon content on the price of carbon steel?

A: The price of carbon steel is relatively low compared to other materials, but it can vary based on carbon content. Low-carbon steel is generally more affordable due to its more straightforward production process and softer properties. Higher carbon steels are more expensive due to the additional processing required to achieve desired strength and hardness levels.

Q: Why is plain carbon steel a common form of steel in construction?

A: Plain carbon steel is a common form of steel in construction because it is relatively cheap and provides a good balance of strength, ductility, and weldability. These properties make it suitable for a wide range of structural applications, such as beams, columns, and reinforcing bars.