Stainless steel 18-8 is one of the most used steel alloys in the 300 series due to its effectiveness and multilateral usage throughout countless industries. In this blog, I will provide details about 18-8 stainless steel, from its very make-up to its diverse application around the globe. Readers pertaining to manufacturing, construction, or some other industry will learn about the importance of this alloy through its relatively great corrosion resistance and strength. Suppose you are a materials engineer, a producer, or someone curious about the metallurgy of stainless steel. This blog will help you understand the critical aspects of 18-8 stainless steel in contemporary engineering and design.

What is the chemical composition of 18-8 stainless steel?

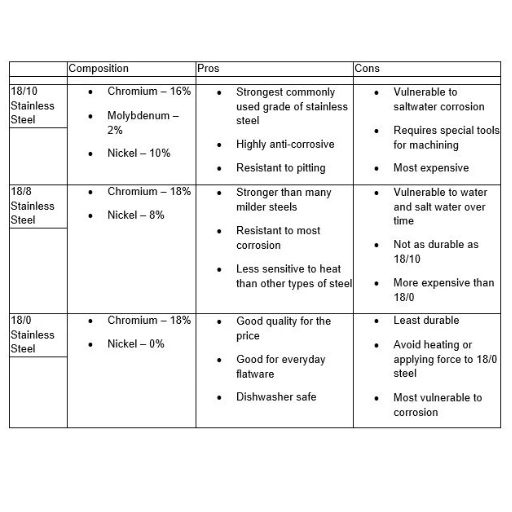

The term stainless steel 18-8 comes from its makeup, which is approximately 18% chromium and 8% nickel. In combination, these elements grant the alloy superb corrosion resistance and lasting durability. The rest of the makeup includes primarily iron and other elements like carbon, manganese, and silicon, which improve the alloy’s mechanical features and workability.

Understanding the 18% chromium and 8% nickel content

The 18% chromium component found in 18-8 stainless steel alloys provides a passive oxide layer on the surface, protecting the metal from rust, thus providing excellent corrosion resistance. The 8% nickel included in the alloy serves to toughen the alloy, making it further resistant to corrosion. Together, these two components enhanced the balance of strength, flexibility, and resistance to heat and chemicals, allowing 18-8 stainless steel to be widely used in industrial equipment, medical instruments, and cookware.

Other elements present in 18-8 stainless steel

In addition to chromium and nickel, 18-8 stainless steel consists of minor elements that aid its functions. These comprise:

- Manganese (up to 2%) supports the development of austenite, thus improving strength and wear resistance.

- Silicon (up to 1%): Provides oxidation resistance and contributes to overall strength at elevated temperatures.

- Carbon (up to 0.08%): Hardness and tensile strength is [] increased by carbon. However, the corrosion resistance is not significantly compromised with the low percentage retained.

- Phosphorus and Sulfur (limited to 0.045% and 0.03%, respectively): These contaminants remain within certain bounds to not significantly reduce ductility and corrosion resistance.

These resistance elements are integrated into the alloy proportion to provide durability, versatility, and adaptability across different applications.

How does the composition compare to the 304 and 316 grades?

The composition of this alloy differs from the 304 and 316 grades due to the intentional infusion of nitrogen and molybdenum that improves tensile strength and corrosion resistance. 304-grade stainless steel is well-known for general-purpose applications because it possesses a contemptible balance of other strength and corrosion resistance. At the same time, 316-grade is known for its super resistance to chloride because of its higher molybdenum content. This alloy, in contrast, is designed to be rigid yet versatile. The imposed restriction on phosphorus and sulfur allows for more excellent ductility and resistance, making it a superior alloy for harsher conditions.

What are the mechanical properties of 18-8 stainless steel?

Due to its exceptional mechanical properties, 18-8 stainless steel is widely used in different sectors. The material’s tensile strength lies within 70,000 to 90,000 psi, and its yield strength is estimated to be around 25,000 to 50,000 psi. It is relatively ductile and tough, meaning the material does not easily break when subjected to considerable force. Moreover, it possesses remarkable resistance to wear and impact, making it ideal for application in both standard and extremely harsh conditions. The material exhibits outstanding corrosion resistance, which adds to its usefulness and dependability.

Tensile Strength and Yield Strength of 18-8 Stainless Steel

18-8 stainless steel is an austenitic-based alloy that is highly used and adaptable. Its yield strength tends to be around 25,000 to 50,000 psi depending on the specific processing and heat the material undergoes, so its tensile strength of 70,000 to 90,000 psi is approximately. All the above-mentioned details show that stainless steel can endure and resist any changes induced on it by stressing it, thus making it useful for construction, food processing, or marine applications. This, combined with superb corrosion resistance, displays why such alloys are so useful when extreme conditions are faced.

Ductility and Hardness Characteristics

Making it a versatile material in various industries, 18-8 stainless steel demonstrates excellent ductile-hardened properties. The term ductility refers to the ability of the material to undergo deformation due to tensile stress (stretching) without breaking, and an aspect of 18-8 stainless steel’s structural composition that makes it so adaptable is its chromium and nickel proportions. Its elongation before breaking is usually around 40% to 60%, subject to precise processing and fabrication conditions, making it suitable for deep drawing or bending.

Conversely, the hardness of 18-8 stainless steel, which is reasonably ductile, is measured using Brinell (HB) or Rockwell (HRB) methods. It generally has a B-scale Rockwell hardness of about 70 to 95, depending on the treatment and working strain it has undergone. After applying severe plastic deformation processes, hardness improves while ductility deteriorates. This balance of ductility and hardness is favorable because the steel can undergo various stresses from construction works for fasteners, fittings, and even surgical instruments. These characteristics confirm why 18-8 stainless steel is preferred in high-performance surroundings.

Impact of cold working on mechanical properties

Cold working improves the mechanical properties of metal such as 18-8 stainless steel. It improves tensile strength and hardness because of the work-hardening effect, but ductility is reduced. This trade-off can be significant in achieving the right balance for specific needs. For instance, cold working strengthens the material by aligning and densifying the crystal structure. But, overdoing it can make the material brittle. Thus, careful process monitoring is essential to ensure the right mechanical properties are attained.

What physical properties make 18-8 stainless steel unique?

The 18-8 stainless steel is unique because of its strength, resistance to corrosion, and ductility. Its composition, which includes 18% chromium and 8% nickel, enables it to resist rust and oxidation well, even in extreme environments. Moreover, it has good tensile strength and ductility, which makes it applicable to many industries needing appliance longevity and strength. This alloy is also non-magnetic when in an annealed state and retains mechanical integrity at different temperatures.

Corrosion resistance capabilities of 18-8 stainless steel

The corrosion resistance of 18-8 stainless steel is outstanding, primarily because of its chromium content, which is 18%. Chromium makes stainless steel durable since it passes into its oxide form, hindering further oxidation and rust. Nickel, which is added to increase the content to 8%, improves corrosion resistance in mildly acidic and alkaline conditions. This material is also quite resistant to pitting and crevice corrosion in mild chemical environments. Its relevant corrosion resistance parameters include:

- Chromium Content: 18% – ensures the creation of an oxide layer.

- Nickel Content: 8% – enhances the stability of the alloy but is also mildly corrosive.

- Operating Temperature Range: Up to 870°C (1598°F) for intermittent use and 925°C (1697°F) for continuous use.

- Corrosion Resistance Rating: Excellent in aqueous, low salinity, and humid conditions.

Despite this, 18-8 stainless steel will not perform well in highly chlorinated or saline settings, such as seawater, without extra treatment or alternative alloys that provide more excellent corrosion resistance.

Magnetic properties: Is 18-8 stainless steel magnetic?

Stainless steel 18-8, generally consisting of grades 304 and 316, is described as non–magnetic in its annealed state due to its austenitic microstructure. However, some magnetism may be present due to specific circumstances, such as cold working or welding and the development of martensite or ferrite.

Essential Notes on Magnetism for the 18-8 Stainless Steel:

- Non-Magnetic Within Annealed State: Non-magnetic due to the dominance of austenite.

- Cold Working: Bending, drawing, or any cross-sectionally lessened deformation does lead to partial magnetism, which varies with the degree of the deformation.

- Technical Parameters:

- The value for magnetic permeability for steel in the annealed condition is approximately 1.01 to 1.02, which is very close to a vacuum (1).

- While magnetism can occur in stainless steel 18-8, it isn’t essential for most practical uses.

For cases where the absence of magnetism is crucial, other high-purity austenitic steels or coatings would be required.

Thermal Expansion and Conductivity Characteristics

The coefficient of thermal expansion for this material is relatively moderate, therefore its dimensions remain stable within certain limits of temperature. It has lower thermal conductivity than copper and aluminum, but it is more than adequate for uses where heat flow is not a primary concern. This feature allows it to be used in environments that need to maintain constant performance under thermal stress. For specific and critical thermal characteristics such as high thermal conductivity or low expansion, specialized materials should be reserved. Particular data sheets will provide more precise information for those seeking it.

How does 18-8 stainless steel compare to other 300 series stainless steels?

Due to its versatility, 18-8 stainless steel is one of the most popular alloys from the 300 series, which is the least corrosion-resistant. Its durability and resistance to corrosion are phenomenal. Compared to other 300 series stainless steels, its balanced chromium (18%) and nickel (8%) composition is best for various products. This grade is widely used because its counterpart, 316 stainless steel, which has molybdenum in it and provides better resistance to corrosion in marine or acidic environments, is more expensive. 18-8 is stainless steel, which is cost-effective and suitable for general-purpose use. Its weldability, strength, and resistance to oxidation make this product more and more reliable for different industries.

18-8 vs. 304 Stainless Steel: Similarities and Differences

Both 304 grade and 18-8 stainless steel belong to a close-knit family, where 304 stainless steel is a member of the 18-8 group. As with all other members in the 18-8 category, these two contain close to 18% chromium and about 8% nickel. Because of their composition, this group is highly corrosion-resistant and durable, performing well for many applications. Both types are non-magnetic in the annealed condition and have excellent formability and weldability, making these materials adaptable in various fields.

Key Differences

While referring to a broad category of stainless steels possessing 18% chromium and nickel, 18-8 is a subset of stainless steels, whereas 304 is a specfic grade of 304 stainless steel. 304 adheres to stricter material specifications and often includes trace elements like manganese and carbon, with a typical carbon content of up to 0.08%. Unlike the other types of stainless steel, 304 stainless steel possesses some increased mechanical attributes such as:

- Yield strength: ~30,000 psi (207 MPa)

- Tensile strength: ~74,000 psi (510 MPa)

- Elongation at break: 40% or more

While both types of materials are suitable for general applications, 304 stainless steel’s compliance to stringent standards makes it more desirable for highly accurate and traceable applications than 18-8 stainless steel.

18-8 vs. 316 stainless steel: When to choose which grade

The distinction between choosing 18-8 or 316 stainless steel hinges mainly on the intended application and the surrounding environment. If the purpose is general, I would select the 18-8 option as its corrosion resistance is adequate, and strength is provided in moderate levels. However, if the application has severe corrosive surroundings with saltwater or chlorides in the mix, I would choose 316 stainless steel as it has a higher molybdenum content, increasing its resistance to corrosion and pitting. Even though this option is more expensive, 316 remains the best choice for extreme performance or marine use.

Advantages of 18-8 over 400 series stainless steels

18-8 stainless steel, belonging to the austenitic family, offers a set of advantages compared to 400 series stainless steels of the ferritic and martensitic classes. Leading the pack, the 18-8 stainless steel is much more corrosion-resistant because of the increased levels of nickel and chromium, making it more useful for moderately corrosive or humid conditions. Furthermore, unlike 400 series grades, this variety stays non-magnetic when annealed. This and its excellent formability and weldability make it useful in manufacturing processes. Last, the 18-8 grade offers better ductility and toughness, especially when considering lower temperatures, unlike 400 series grades, which makes it appealing for demanding applications.

What are the main applications of 18-8 stainless steel?

The properties and versatility of the material enable the broad adoption of 18-8 stainless steel across different industries. Its superior corrosion resistance allows it to be used in kitchenware, food processing equipment, and medical instruments. The outstanding strength of 18-8 steel ensures that it is helpful in the aerospace and electronics industries. Other non-magnetic industries such as construction, automotive, and chemical processing also benefit from 18-8 due to its formability and weldability, which allow the fabrication of stronger and durable structures.

Use of 18-8 stainless steel in food processing equipment

Knowing the unique features of the 18-8 stainless steel, it is evident that this material is best suited for food processing equipment. While working in the food industry, the most crucial concern is contamination, which is avoided because of the high corrosion resistance of 18-8 stainless steel in acidic and moist environments. In addition, it does not react with food, making leaching or chemical reactions impossible, thus improving food safety. The grade is easily maintained by cleaning, which helps uphold hygiene standards in the food industry. The material consists of 8% nickel and 18% chromium, causing nonreactive leaching and flexibility, maintaining high corrosion resistance. Its yield strength of about 210 MPa and tensile strength of 520 MPa ensures the material’s reliability in demands from the processing environment. All these reasons make it a trusted material for food-grade applications.

Industrial and Architectural Applications

Due to its outstanding physical and chemical properties, 18-8 stainless steel is primarily used in manufacturing and construction. Its unique resistance to corrosion allows it to excel in chemically hostile settings, humid conditions, and fluctuating temperatures, factors that are critical to industrial machinery and chemical processing plants. The material’s strength and ductility, with a tensile strength of about 520 MPa and yield strength of 210 MPa, make it a bolted sword for structural beams and columns as well as supports and connectors.

In construction, 18-8 stainless steel is significant for its aesthetic appeal and practicality. Its polished finish adds glamour and modernity to building handrails, facades, and cladding. Also, the alloy’s resistance to discoloration and staining sustains its appearance over a long period of time with little effort. This allows intricate designs to be manufactured so that they are sculpted. Along with compliance with safety regulations and being a highly durable material, 18-8 stainless steel is preferred for functional and decorative uses in many industries.

Medical and laboratory uses of 18-8 stainless steel

Due to remarkable corrosion resistance, ease of sterilization, and interaction with biological processes, 18-8 stainless steel is typical in medical and laboratory environments. Stainless steel aids in minimizing adverse biocompatibility reactions, so it is found in surgical instruments, medical devices, and implants. The stainless steel alloy is also used in autoclaves, test tubes, and laboratory storage containers because it is chemically robust, can endure high temperatures, and can be cleaned many times. Stain steel’s strength, hygiene, and durability make it essential in these critical fields.

References

- Amardeep Steel Blog: 18-8 Stainless Steel – Properties and Applications

- Solitaire Overseas Blog: 18-8 Stainless Steel – A Guide of Properties and Applications

- CHISEN®: What is 18/8 Stainless Steel | Forging Materials

Frequently Asked Questions (FAQ)

Q: What is 18-8 stainless steel and how does it differ from other stainless steel grades?

A: 18-8 stainless steel is a type of stainless steel that contains approximately 18% chromium and 8% nickel. It belongs to the 300 series of austenitic stainless steel and is known for its excellent corrosion resistance and versatility. This composition distinguishes it from other stainless steel grades, making it a widely used material in various industries.

Q: What are the key material properties or physical properties of 18-8 stainless steel?

A: 18-8 stainless steel material properties include excellent corrosion resistance, good formability, and non-magnetic characteristics. It also exhibits a relatively low coefficient of thermal expansion, high ductility, and a combination of strength and toughness. These properties make it suitable for various applications in various environments.

Q: How does the composition of 18-8 stainless steel enhance its properties?

A: The composition of approximately 18% chromium and 8% nickel in 18-8 stainless steel provides a balance that enhances its properties. The chromium content forms a protective oxide layer, improving corrosion resistance, while the nickel content stabilizes the austenitic structure, contributing to its non-magnetic nature and improving formability. This composition results in superior properties compared to many other steel types.

Q: What are some typical applications of 18-8 stainless steel?

A: Due to its properties and applications, 18-8 stainless steel is widely used in various industries. Typical applications include kitchen utensils, food processing equipment, chemical industry components, architectural trim, and medical instruments. Its corrosion resistance and durability make it suitable for applications requiring frequent cleaning or exposure to harsh environments.

Q: Are there different grades within the 18-8 types of stainless steel?

A: There are several grades within the 18-8 types of stainless steel. The most common grade is 304, but other grades such as 302, 301, and 303 also fall within this category. These grades have slight variations in composition that can make certain grades more resistant to specific environments or better suited for particular manufacturing processes.

Q: How do the mechanical properties of 18-8 stainless steel compare to other materials?

A: The mechanical properties of 18-8 stainless steel are generally superior to those of many other materials. It offers a good balance of strength, ductility, and toughness. Compared to carbon steels, it has better corrosion resistance and maintains its properties at both high and low temperatures. However, it may not be as strong as some high-strength alloy steels or as lightweight as aluminum alloys.

Q: How is 18-8 stainless steel classified by the American Iron and Steel Institute (AISI)?

A: The American Iron and Steel Institute classifies 18-8 stainless steel within the 300 series of austenitic stainless steels. Specifically, grades like 304 and 302, which are common 18-8 types, are designated by AISI numbers. This classification system helps in identifying the composition and properties of the steel, making it easier for manufacturers and engineers to select the appropriate grade for their applications.

Q: Can 18-8 stainless steel be further treated to enhance its properties?

A: Yes, 18-8 stainless steel can be treated to enhance its properties. While it cannot be hardened by heat treatment like some other steel types, its properties can be improved through cold working, which increases strength. Additionally, surface treatments like electropolishing can enhance corrosion resistance, while nitriding can improve wear resistance in certain applications.