Forging stainless steel is a combination of craft and technique. It demands accuracy, skill level, and a comprehensive understanding of the material’s characteristics. This guide aims to help you develop a keen sense of the entire forging process concerning stainless steel, especially about the mastery of forging temperatures. In this post, we will highlight the significance of maintaining control over the temperature, its impact on the material’s strength, durability, and corrosion resistance, and ways to achieve the correct balance throughout the forging process. This article will empower beginners and veterans alike with the tips and insights necessary to manufacture stainless steel products with remarkable quality and efficiency.

What is the Optimal Stainless Steel Forging Temperature?

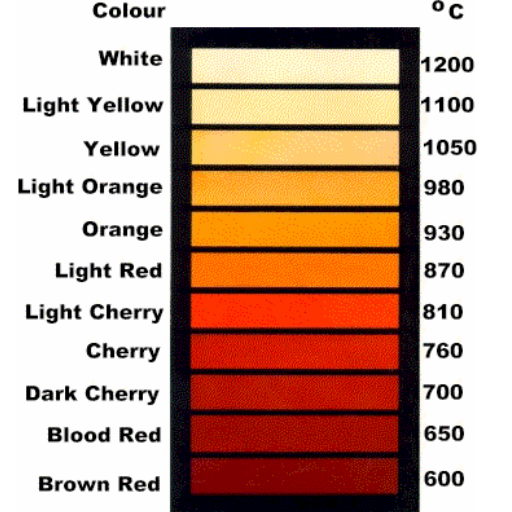

The ideal forging temperature of all grades of stainless steel falls between 1900F-2300F (1038C-1260C). Forging is generally easier when these temperatures are reached, but do not exceed them as malleable temperature limits of the material. If the temperature exceeds, there is a realistic chance of dealing with oxidation or grain growth that would ruin the steel. At the same time, lower ranges may result in cracking or incomplete deformation. Precise monitoring and control of the temperature at which the forging is done is essential to achieve the ideal results in the product.

Understanding the Basics of Stainless Steel Forging

Forging stainless steel, I know how critical it is to control temperatures to sustain malleability and structural integrity. From my research, overheating causes oxidation and grain growth, which is highly detrimental to durability. Working at suboptimal temperatures increases the chances of cracking and poor shaping. I would always ensure control over the precise process temperatures during the working stages to achieve the best results and produce stainless steel with strong, durable, and well-formed components.

Why Temperature Matters in Forging Stainless Steel

The forging temperature of stainless steel is critical because it significantly affects the work and the result of the finished part. Like any other type of steel, stainless steel has specific parameters of work temperature, and the forge range is between 1900 and 2300 degrees Fahrenheit (1038 to 1260 degrees Celsius). The orderly or each within that range will provide workability without ruining the fine structure of the steel. If that range is exceeded, it can cause oxidation issues or excessive grain growth, weakening iron. Forging below that range can lead to cracking and incomplete deformation due to a lack of necessary ductility.

Turning temperature outside the strict range will make either deformation or breaking easy, thus ensuring the production of high-tier stainless steel pieces. During the entire process, the temperature regime and other formed parameters must be monitored and adjusted to achieve the desired strength and toughness without undesirable damages weakening the part.

How to Determine the Best Temperature for 304 Stainless Steel

To heat 304 stainless steel for different processes, I determine the most suitable temperature considering the application and the required features. To achieve maximum strength and corrosion resistance, I increase the temperature to between 1900°F ~ 2050°F (1038°C ~ 1121°C) and then cool it rapidly after it reaches its annealing stage of 2050°F (1121 °C). It is crucial to keep the temperature within the correct range for processes like welding or forming to prevent structural weakening. Effective temperature management and monitoring enable the steel to perform and endure over time.

How Does Heat Treatment Affect the Mechanical Properties of Stainless Steel?

Heat treatment processes improve stainless steel’s properties by changing its microstructure. For example, annealing can improve steel’s ductility and toughness, while hardening can increase strength and wear resistance. Optimal hardness and reduced brittleness achieved through quenching and tempering make the steel resilient under stress. Moreover, proper treatment prevents carbide precipitation, which would lessen corrosion resistance and negatively affect the structure’s integrity.

The Role of Annealing in Stainless Steel Forging

By shaping during stainless steel forging, I can significantly improve its workability and overall performance. Improvement is achievable through annealing, where internal stress is relieved, and the grain structure is refined. This treatment dramatically enhances the material’s ductility, contributing to efficient forging operations. In addition, oxygen protection during fabrication processes is restored to ensure corrosion resistance. Furthermore, annealing guarantees that the material performs well under demanding conditions. Monitoring the annealing cycle produces softer stainless steels, optimizing the materials for their intended uses while improving their durability.

Effects of Quenching on Strength and Corrosion Resistance

The stiffness of stainless steel is considerably improved by quenching, which usually involves turning it off in water, oil, or air after heating it to a very high temperature. Rapid cooling of the metal prevents the formation of undesired crystal structures like ferrite or pearlite while facilitating crystal martensite, which is more rigid and more substantial. As a downside, the combined effects of residual stresses or inadequate cooling rates can lessen the corrosion resistance.

To strike a balance between strength and resistance to corrosion, some parameters can be set:

- For austenitic stainless steels, the heating temperature range is from 1,000-1,100°C (1,832-2,012°F).

- Cooling Medium:

- Air, which reduces the chances of cracking while cooling water, is effectively used for rapid cooling to maximum hardness.

- Oil decreases deformation and stress while providing moderate cooling.

- Cooling Rate: A rate capable of adequately suppressing carbide precipitation while assuring martensite formation.

- Post-Quenching Treatments:

- Residual stress relief is achieved by annealing to reduce residual stresses.

- If required, restore the resistance to corrosion by passivation (for example, using baths of nitric acid).

These cooling parameters enable the optimization of the quenching process regarding the achievable mechanical properties and the required extent of corrosion resistance for rigorous applications.

Exploring Precipitation Hardening Techniques

Precipitation, or aging, hardening is a technique to increase the strength of certain alloys. This technique has three main stages: solution treatment, quenching, and aging. In the solution treatment phase, the alloy is heated to dissolve the solute particles, forming a single-phase solution. The material is then rapidly cooled or quenched to trap the solute atoms in the matrix. Finally, the aging process is controlled to allow the formed fine particles to precipitate out, thereby hindering dislocation motion and increasing strength. If done correctly, these steps improve mechanical properties within the material. This technique becomes essential in the aerospace and automotive industries, where high-performance materials are crucial.

What Are the Common Stainless Steel Grades Used in Forging?

Because of their exceptional qualities, the following grades of stainless steel are widely used for forging:

- Grade 304: Because of its high resistance to corrosion, durability, and formability, grade 304 is often called the workhorse of stainless steel. Due to these factors, it is widely used in many areas.

- Grade 316: Grade 316 is ideal for marine, chemical, and medical industries because of its enhanced resistance to corrosion, especially with chloride.

- Grade 410: This is used in cutlery and tools due to its moderate corrosion resistance and good strength and wear resistance.

- Grade 420: Grade 420 is used for surgical instruments and knives. Its higher hardness and strength give it sharper edges.

- Grade 430: Commonly used in the automotive industry and for kitchen appliances due to its resistance to oxidation.

Machinability, heat and corrosion resistance, strength, and other application-specific factors are considered when making these selections.

Characteristics of 304 and 316 Stainless Steel

Stainless steels, 304 and 316, have become very popular over the years due to their resistance to corrosion and versatility, but they also have different properties. Stainless steel grade 304 is one of the most economical and valuable alloys because it has excellent resistance to rust in most environments and good weldability. Because of these properties, it is widely used in kitchen equipment, storage tanks, and piping. However, 316 stainless steel contains molybdenum, which improves the alloy’s resistance to chlorides and other harsh chemicals, making this alloy better suited for marine environments or chemical processing. Both have been proven to be durable and reliable. However, 316 is preferred in more aggressive applications.

Comparing Carbon Steel and Stainless Steel in Forging

Carbon steel and stainless steel forgings have distinct benefits that may be more useful depending on the situation. Carbon steel is almost always chosen over stainless steel due to its greater strength, impact resistance, and cost-effectiveness. While carbon steel does lose in some areas compared to stainless steel, namely corrosion mitigation, it’s still one of the most commonly used types of steel for heavy-duty tools and structural components.

Stainless steel is the clear winner when mitigating corrosion, the most critical factor, such as during food processing, medical tool fabrication, or even marine uses. Logically, some industries prefer stainless steel due to its esthetical finish and strength-to-weight ratio. But when trying to forge stainless steel, it’s often found that it is more challenging to work with due to the toughness of the metal and the energy needed to forge it.

When making a decision, some technical parameters stand out:

- Corrosion Resistance: For example, grade 304 and 316 resonance stainless steel outperforms carbon steel in corrosion resistance,

- Hardness (Rockwell): Carbon steel often falls within 55-62 HRC depending on the alloy, whereas stainless steel usually sets this benchmark lower due to its chromium content.

- Tensile Strength: Carbon steel acquires tensile strengths of 400-1800 MPa, whereas stainless steel tends to have a tensile strength range of 480-1050 MPa, depending on the grade.

- Forgeability: Compared to stainless steel, carbon steel has a higher workability due to its lower toughness.

- Density: Like carbon steel, stainless steel has a density of 8.00 g/cm³, making them relatively equal, as carbon steel’s density is approximately 7.85 g/cm³.

Choosing one or the other depends on the specifics of your project, such as corrosive exposure, needed durability, or cost efficacy.

How Does Corrosion Resistance Impact the Stainless Steel Forging Process?

The corrosion resistance process directly influences the choice of materials, the methods used, and the after-treatments associated with forging. High levels of chromium in stainless steel impart resistance to corrosion due to the protective oxide film covering its surface. This enables forged stainless steel components to function in highly corrosive environments with minimum upkeep. On the other hand, optimal corrosion resistance requires consistent monitoring of the forging and heat treatment processes to achieve well-controlled chrome protection layer formation. Moreover, practical handling and finishing of the surface is necessary to maintain this resistance in the product.

The Importance of Chromium in Corrosion Resistance

Corrosion resistance is improved due to chromium’s ability to create a thin, passive oxide layer on the surface of stainless steel. Known as the chromium oxide film, this layer is a barrier from gas and moisture that may damage the metal underneath. For effective corrosion resistance, stainless steel must have at least 10.5% chromium raised to 16-18% in more demanding applications.

Some important ones are:

- Chromium Content: Minimum of 10.5%; ideal range for enhanced resistance is 16-18%.

- Heat Treatment: An adequate annealing temperature is required to fine-tune the alloy’s uniformity and properties, typically around 1850F-2100F (1010C-1150C).

- Surface Treatment: Polished surfaces tend to trap corrosive agents less than rough surfaces, improving the protective oxide layer.

Accurate control during the forging and finishing stages of production is crucial for making stainless steel weather—and corrosion-resistant.

Understanding Carbide and Sulfur Effects on Corrosion

Stainless steel alloys are significantly impaired in their ability to resist corrosion because of carbides and sulfur. The excess carbon in the alloy results in the formation of carbides, which can cause chromium depletion at the grain boundary, which reduces the ability of stainless steel to sustain its protective oxide layer and causes intergranular corrosion. On the contrary, sulfur is added in some cases to enhance machinability, but over-adding sulfur tends to create inclusions that speed up pitting and crevice corrosion. It is essential to find a balance with these additives to maximize corrosion resistance while maintaining the physical and processing features of the alloy.

What Are the Best Practices for Forging Stainless Steel?

It is essential to control the temperature when forging stainless steel to prevent thermal shock and maintain the integrity of the material. The alloy should be preheated uniformly to the appropriate forging temperature, Between 1900°F and 2300°F (1038°C – 1260°C) depending on the alloy grade. Be careful not to overheat the alloy, leading to grain growth and diminished mechanical properties. Post-forging, use controlled cooling methods to reduce stress and distortion. Furthermore, clean and well-maintained tools may be used to prevent emissions and surface defects. Lastly, forge the alloy with specific heat treatment after forging to maximize corrosion resistance and refine the grain structure for fully optimized performance.

Essential Tools and Techniques in the Forging Process

Precise tools and well-set processes are critical to get the best results while forging. Hammers, anvils, tongs, and presses are essential for creating the force to shape the given material. Creating die sets and correctly heating the specific metal in the furnace or induction heaters to the required forging temperature is very important. Maintaining the tool’s lubrication and using coolant can prevent friction and wear out on the tools over time, enhancing performance in the duration of use.

Open-die forging is one key technique for efficiently achieving larger, simpler shapes, while closed-die forging is more accurate and ideal for complex designs. Notably, isothermal forging is another essential method for ensuring uniform grain flow and strength with high-performance components. For every step during the forging process, efficient material handling and cooling to the right temperature are critical. All these tools and techniques guarantee excellent mechanical properties and precise and dependable parts for industrial use.

Common Challenges in Forging Stainless Steel and How to Overcome Them

The forging of stainless steel poses many challenges, including the high work-hardening rate. As most engineers know, the higher the work-hardening rate, the lower the potential for shaping the part and the greater the risk of cracking. I start by preheating the stainless steel to a forging temperature of between 1900°F and 2200°F; the preheating temperature range varies with the alloy. Preheating reduces the amount of force during deformation and prevents crack formation in the steel.

There is also the issue of further oxidation of the steel after forging due to surface oxidation and microstructure changes. My method to control oxidation is post-forging treatment control, where I set the right annealing and quenching, followed by pickling if needed, to enhance the surface finish and quality of the part.

Applying high temperature and pressure increases the chances of tool wear and die failure. As a solution, I utilize heat-resistant, durable tooling and regularly use lubricants specifically designed for high-temperature operations, thereby enhancing the longevity of my tools and improving the ease of production. Implementing effective quality control at all steps is essential to overcoming these issues.

Recommended Heat Treating Methods for Optimal Results

Considering my experience and research, I suggest annealing, quenching, and tempering as the best heat-treating methods. Each offers a different benefit, such as improved machinability, increased hardness, and strength, or increased toughness while lowering brittleness. I consistently achieve the desired results by applying the correct method and accurate temperature control relative to the material and application.

References

- A Guide to Stainless Steel Forgings | 304 SS – Discusses forging temperatures for different stainless steel grades.

- STAINLESS STEEL FORGINGS – Covers mechanical properties and forging techniques for stainless steel.

- Stainless Steel Forging Process: A Comprehensive Guide – Explains high-pressure forging techniques and their benefits.

Frequently Asked Questions (FAQ)

Q: What is the ideal forging temperature for stainless steel?

A: The ideal forging temperature for stainless steel depends on the grade. For most austenitic types, such as 304 stainless steel, the recommended forging temperature is around 1900°F to 2300°F. Staying within this range helps maintain the stainless steel’s ductility and prevent issues such as carbide precipitation.

Q: Can 304 stainless steel be forged effectively?

A: Yes, 304 stainless steel can be forged effectively. It is part of the 300 series and is known for its excellent corrosion resistance and formability. The forging process improves its mechanical properties, such as strength and ductility, making it suitable for various applications, including valve bodies and shafts.

Q: What challenges might arise when forging stainless steel?

A: Some challenges when forging stainless steel include maintaining the proper temperature to prevent the material from crumbling if forged cold and avoiding carbide precipitation, which can occur if the material is overheated. Additionally, achieving a smooth flow that follows the stainless steel part is crucial to prevent defects.

Q: Why is stainless steel widely used in forging?

A: Stainless steel is widely used in forging due to its excellent corrosion resistance, strength, and ability to withstand high temperatures. These properties make it ideal for producing parts such as valve trim, stainless steel knives, and various machine components that must endure harsh environments.

Q: What is the role of alloy steels in stainless steel forging?

A: Alloy steels, including different grades of stainless steel, play a crucial role in forging by providing enhanced mechanical properties for specific applications. For example, adding chromium and nickel to create 304 ss or 316 ss enhances corrosion resistance and durability.

Q: How does die forging benefit the production of stainless steel parts?

A: Die forging benefits the production of stainless steel parts by allowing for precise control over the shape and size of the final product. This method ensures consistent quality and minimizes material waste, making it ideal for producing complex components like valve bodies and machine parts.

Q: What are the differences between 304 ss and 316 ss in forging?

A: The chemical composition is the main difference between 304 ss and 316 ss in forging. 316 ss contains molybdenum, which enhances its resistance to corrosive environments, making it more suitable for marine applications. Both grades offer excellent ductility and strength, but 316 ss performs well in harsh conditions.

Q: How can hammer blows affect the forging process of stainless steel?

A: Hammer blows during forging can significantly affect the final properties of stainless steel by shaping the metal and refining its grain structure. Properly executed hammering can improve the material’s strength and ductility, but excessive or uneven blows can cause defects or uneven flow that follows the stainless steel part.

Q: What precautions should be taken when using a gas forge for stainless steel?

A: When using a gas forge for stainless steel, it’s essential to monitor the temperature closely to avoid overheating, which can cause carbide precipitation or material damage. Additionally, using a reducing atmosphere can help prevent oxidation and maintain the integrity of the stainless steel surface.