The strength, usefulness, and robust stamina of 304 stainless steel render it one of the most ubiquitously utilized materials in industries as diverse as construction and food processing. From a scientific perspective, it is the stainless steel’s 304 alloy composition, which encompasses chromium and nickel, that profoundly enhances the steel’s versatility and applicability across numerous advanced modern technologies. Under 304 alloys, this steel exhibits significant resilience to extreme conditions: its splendid anti-corrosive properties paired with a generous melting point result in stainless 304 steel being suitable, among others, for the food industry, construction work, and manufacturing.

What is 304 Stainless Steel?

The aim of this blog is to synthesize the melting point static of 304 stainless steel with its chemical make up and the practical drawbacks and benefits that affect its usability. In learning the steel’s properties, this post illuminates why it is the most preferred material in engineering and manufacturing for industrials when they consider both the economic and engineering perspectives.

Detailed Composition of 304 Stainless Steel

304 stainless steel is an austenitic alloy with fantastic corrosion resistance and luster due to its 18-20% chromium and 8-10.5% nickel composition. It also contains up to 2% manganese, 1% silicon, and small quantities of carbon, 0.08% at most. Phosphorus and sulfur in trace amounts, usually below 0.045% and 0.03% respectively, are also present. Its composition offers remarkable durability, oxidation resistance, and ease of processing, making it a sought-after structural material.

Differences Between 304 and Other Stainless Steel Grades

304 stainless steel is one of the most popular grades due to its versatility and excellent properties, but it differs from other stainless steel grades in that it has several unique characteristics.

- 304 vs. 316

The difference of 316 compared to 304 is the addition of molybdenum. This increases 316’s corrosion resistance, especially in chloride-heavy areas like marine or chemical environments.

- 304 Composition: ~18-20% chromium, ~8-10.5% nickel.

- 316 Composition: ~16-18% chromium, ~10-14% nickel, ~2-3% molybdenum.

Key Advantage: 316 is more resistant to pitting and crevice corrosion than 304.

- 304 vs. 430

430 is a non-magnetic grade as it is a ferritic stainless steel, which has lower corrosion resistance. 304 is austenitic and non-magnetic under standard conditions.

- 304 Composition: Higher nickel content (~8-10.5%) ensures non-magnetic behavior.

- 430 Composition: ~16-18% chromium, <0.75% nickel.

Key Advantage: 304 has better weldability and strength, but 430 is advantageous in less demanding conditions due to lower cost.

- 304 vs. 201

Grade 201 stainless steel is an option with higher manganese content and lower nickel content, which makes it more economical, but impacts its corrosion resistance and durability.

- 304 Composition: ~18-20% chromium, ~8-10.5% nickel.

- 201 Composition: ~16-18% chromium, ~3.5-5.5% nickel, ~5.5-7.5% manganese.

Key Advantage: 304 is more resistant to corrosion and suitable for more demanding applications.

These differences demonstrate 304’s struggle to remain affordable while enduring harsh corrosive environments and being easily worked with, thus illustrating 304’s ability to be dominantly used in many industries while carefully choosing materials based on their intended use.

Applications of 304 Stainless Steel

Because of its versatility, durability, and exceeding corrosion resistance, 304 stainless steel is used all over the world. Listed below are a few of its applications:

- Food and Beverage industry

- Reason: 304 stainless steel is highly non-reactive, making it ideal for storage and food processing.

- Examples: Sinks, food grade containers, kitchen equipment, and utensils.

- Construction and Architecture

- Reason: 304 stainless steel has high aesthetic value in addition to being highly resistant to corrosion ensuring longevity in structures.

- Examples: Handrails, building facades, and decorative panels.

- Healthcare and Medical Equipment

- Reason: Its high degree of hygienic properties and able to be cleaned with harsh cleaners frequently make 304 stainless steel suitable in medical surroundings.

- Examples: Surgical instruments, medical carts, hospital beds, and sterilization equipment.

- Automotive and Transportation

- Reason: Withstand harsh conditions, wear, and tear due to its durability, makes it suitable for structural and decorative components.

- Examples: Trim, exhaust systems, and other parts of the vehicle.

- Chemical and Petrochemical industry

- Reason: Can withstand damaging chemicals and moderate acid exposure.

- Examples: Piping, tanks, and heat exchangers for the storage and transfer of chemicals.

- Marine applications

- Reason: 304 stainless steel possesses moderate resistance to chloride corrosion, making it suitable for marine and coastal regions.

- Examples: Equipment and rails exposed to salty air or seawater conditions, and boat fittings.

- Industrial Machinery

- Industrial use Is due to the high strength and corrosion resistance of the metal.

- Heavy and other Industries: Springs, fasteners, and other components in storage tanks are used in manufacturing.

Technical Specifications

- Corrosion Resistance: Excellent in mildly corrosive, oxidizing, and other environments.

- Tensile strength: Approximately 515 MPa (minimum)

- Yield strength: Approximately 205 MPa (minimum)

- Operating temperatures: Intermittent use (up to ~870°C), Continuous use (925°C)

- Formability: Easy shape bending and welding.

When balanced with performance, cost-efficiency, and availability, 304 stainless steel maintains diverse applications in numerous industries.

What is the 304 stainless steel melting point?

high melting point offers increased heat resistance and makes it suitable for high temperature applications.

Melting Temperature Range for 304 Stainless Steel

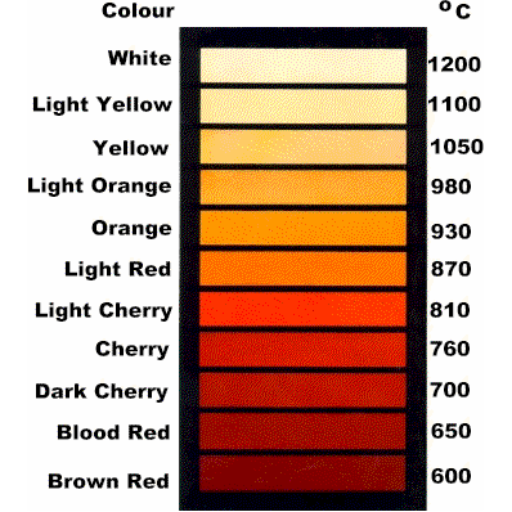

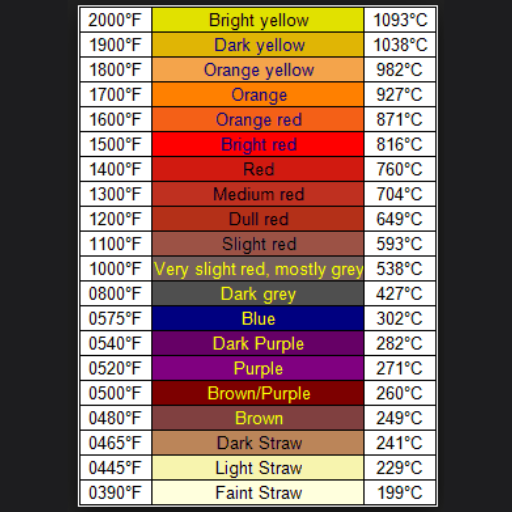

The steel alloy has a relatively high melting point of 1,400-1,450 °C (2,550-2,650 °F), rendering the material exceptionally stable at high temperatures. This characteristic is advantageous for several applications in industrial processing and cookware.

Factors Affecting the Melting Point

Several factors affect the melting point of 304 stainless steel. First, its chemical composition is an important factor. Changes in the amount of chromium and nickel in the alloy can make some differences in the melting range, which is generally between 1,400°C and 1,450°C. Second, some other impurities or alloys such as manganese, silicon, and carbon can also affect the melting point. Increased carbon content, for instance, might decrease the melting point slightly. Lastly, conditions such as pressure do not change the melting point under normal conditions. They do, however, in extreme laboratory conditions, which is the only case where some small changes can be made. These tendencies are the reason 304 stainless steel is as versatile as it is.

How Does the Chemical Composition Affect 304 Stainless Steel?

The properties and performance of 304 stainless steel depend on its chemical composition. The alloy withstands different stressful environments because of the immense corrosion resistive properties chromium and nickel provide. Workability and strength are achieved with carbon while structural control is guaranteed through manganese and silicon. The combination results in an extremely strong, ductile, oxidization resistant material, which is one of the reasons it is widely used in industries and in households alike.

Role of Chromium in 304 Stainless Steel

The role of chromium in the properties of 304 stainless steel is fundamental to its providing remarkable corrosion resistance. This is done by a passive chromium oxide layer forming on the surface, which protects the steel from oxidative or environmental harm and damage. 304 stainless steel, for instance, has a chromium composition of about 18-20%, ensuring that it can withstand rust and corrosion in acidic and humid environments. Furthermore, chromium helps stainless steel retain its shine and polished appearance long after it has been manufactured, making it more attractive. This enhanced durability means that the material can sustainably persist under strenuous use, with reliability unquestionably fortified.

Nickel and Its Impact on Melting Point

Combining nickel into stainless steel alloys serves the purpose of elevating their formability and toughness while also driving down the melting point. The addition of nickel to the alloy raises its resistance to extreme temperatures and mechanical stress, making it particularly valuable for use in the aerospace sector, power plants, and chemical processing. The presence of nickel will undoubtedly stabilize the austenitic structure of steel, granting tremendous resilience and strength that can be retained during very high temperatures or even cryogenic conditions.

Why is the Melting Point Important in 304 Stainless Steel Applications?

The importance of 304 stainless steel’s melting point lies in the fact that it can maintain the material’s structural properties when exposed to high temperature environments. 304 stainless steel is suitable for intense heat applications such as industrial ovens, heat exchangers, and welding because it has a melting range of approximately 2550 Fahrenheit to 2650 Fahrenheit (1399°C to 1454°C). This property guarantees reliability, safety, and durability in harsh operating conditions.

Impact on Fabrication and Welding

In my experience with fabrication and welding, I have found 304 stainless steel to possess remarkable versatility along with ease of welding. The weld joints are less prone to corrosion because its low carbon content reduces carbide precipitation. Furthermore, its formability is favorable for many industrial and commercial applications. The use of stainless steel welding techniques with proper filler metals achieves optimal performance and durability in and out of service.

Considerations for High-Temperature Applications

When evaluating 304 stainless steel for high-temperature applications, I verify its temperature limits and associated performance metrics. The material can maintain its structural integrity and oxidation resistance below 1500°F (816°C); therefore, I do not allow operating conditions to exceed this limit. For long-term exposure over 800°F (427°C), I analyze sensitization risks that potentially result in intergranular corrosion. The problem can be alleviated by the use of low-carbon variants such as 304L. Moreover, its thermal conductivity (16.2 W/m·K at 212°F) and thermal expansion (17.2 µm/m·K) are important as they influence the material’s behavior when subjected to temperature fluctuations. Striking a balance with careful selection of materials while adhering to these considerations guarantees reliable and efficient operation in high-temperature environments.

How Does 304 Stainless Steel Compare to 316?

Both 304 and 316 are austenitic alloys, but their composition and corrosion resistance are different. Molybdenum is added to 316 stainless steel to improve pitting and crevice corrosion resistance in chloride-rich environments (ex. marine environments). In comparison, 304 is more economical and offers good corrosion resistance in less aggressive conditions. For chemical and saltwater applications, 316 is common; for general-purpose applications, 304 is often sufficient due to its affordability.

Differences in Corrosion Resistance

Corrosion resistance gaps differ depending on the environments the metals are exposed to. I noticed the difference with 316 stainless steel: it contains molybdenum, which makes it much harder to get corroded in maritime and chemical-heavy environments. On the other hand, 304 stainless steel is economical as it provides strong general corrosion resistance in less aggressive conditions; hence, it can withstand a variety of environments. 316 is the better choice when dealing with saltwater and harsh chemicals, while 304 is common for everyday equipment such as kitchen tools.

Comparing Mechanical Properties

The mechanical properties of 316 stainless steel and 304 stainless steel possess several differences, which are important when considering an application. Both alloys have remarkable durability; however, due to the molybdenum content of 316 stainless steel, it possesses higher tensile strength and greater resistance to deformation under stress than its counterpart.

Below are the technical parameters for mechanical properties of both grades:

- Tensile Strength

- Stainless Steel 304: Approximately 515 MPa (75,000 psi)

- Stainless Steel 316: Approximately 579 MPa (84,000 psi)

- Yield Strength

- Stainless Steel 304: Approximately 215 MPa (31,000 psi)

- Stainless Steel 316: Approximately 240 MPa (35,000 psi)

- Elongation at Break

- Stainless Steel 304: Around 70%

- Stainless Steel 316: Slightly lower, around 60%

- Hardness Rockwell B:

- Stainless Steel 304: Around 82

- Stainless Steel 316: Around 79

It can be seen that both materials are relatively comparable in terms of mechanical performance, however, the slight enhancements of 316 stainless steel when it comes to strength and resistance place it as the favorable alloy to use in more demanding environments. On the other hand, 304 stainless steel is the favorable option for non-extreme applications as it is very cost-effective.

Melting Point Comparison

From my calculation,304 stainless steel has a melting point of approximately 1400 to 1450°F ,and 316 stainless steel has a melting point of 1375-1400°F. While the difference is negligible, the reason why 316 has a lower melting point is due to its increased content of molybdenum. Both materials are thermally stable and can be useful for most applications, but their melting points are seldom the defining factor except in very high-temperature scenarios.

References

- Understanding the Melting Point of 304 and 316 Stainless Steel – TBK Metal

- Stainless Steel Melting Point: Measurement, Influencing Factors – SteelPro Group

- Thickness and Melting Point of AISI 304 Stainless Steel – GlobalSpec

Frequently Asked Questions (FAQ)

Q: What is the melting point of 304 stainless steel?

A: The melting point of 304 stainless steel is typically in the range of 1400-1450°C (2552-2642°F). This melting range is influenced by its composition as an austenitic stainless steel, which includes elements such as nickel and chromium.

Q: What factors contribute to the melting point of stainless steel, particularly grade 304?

A: The melting point of stainless steel, including grade 304, is primarily determined by its alloy composition. The presence of nickel, chromium, and other alloying elements like manganese and silicon affect the melting range and heat resistance of the steel.

Q: How does the melting point of grade 304 stainless steel compare to other types of stainless steel?

A: Grade 304 stainless steel has a melting range of 1400-1450°C, which is similar to other austenitic stainless steels but higher than ferritic and martensitic stainless steels, which typically have lower melting points.

Q: Why is grade 304 stainless steel commonly used in high-temperature applications?

A: Grade 304 stainless steel is commonly used in high-temperature applications due to its high melting point, excellent heat resistance, and superior corrosion resistance, allowing it to be used in environments where high temperatures and corrosive substances are present.

Q: What role does nickel content play in the properties of grade 304 stainless steel?

A: Nickel content in grade 304 stainless steel enhances its corrosion resistance, ductility, and toughness. It also contributes to the austenitic structure, which is crucial for maintaining its strength and stability at high temperatures.

Q: Can grade 304 stainless steel be fabricated easily?

A: Yes, grade 304 stainless steel is known for its excellent formability and weldability, making it easy to fabricate into various steel products. Its ductility and ability to be formed without losing its toughness are key properties.

Q: What are the main applications of grade 304 stainless steel due to its melting point and properties?

A: Due to its high melting point and beneficial properties, grade 304 stainless steel is widely used in industries such as automotive, aerospace, and construction. It’s ideal for applications that require high strength and resistance to oxidation and corrosion.

Q: How does the addition of chromium affect the melting point and properties of grade 304 stainless steel?

A: Chromium is a vital component in grade 304 stainless steel, contributing to its corrosion resistance and oxidation stability. It helps maintain the austenitic structure and slightly increases the melting range, enhancing the alloy’s overall performance.

Q: What are the advantages of using austenitic stainless steel like grade 304 over carbon steel?

A: Austenitic stainless steel, such as grade 304, offers superior corrosion resistance, better formability, and higher ductility compared to carbon steel. These properties make it more suitable for environments with high temperatures and corrosive agents.

Q: How does the melting point of stainless steel influence its fabrication and use in different industries?

A: The melting point of stainless steel, particularly grade 304, influences its suitability for high-temperature applications and ease of fabrication. Its high melting range allows for effective use in industries that demand strong, durable materials capable of withstanding extreme conditions.