Get in touch with us

Leave a message

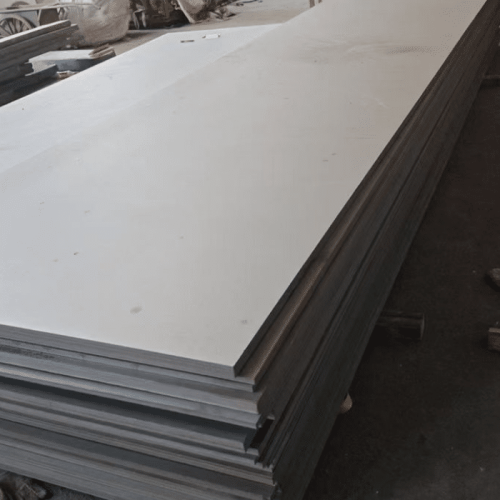

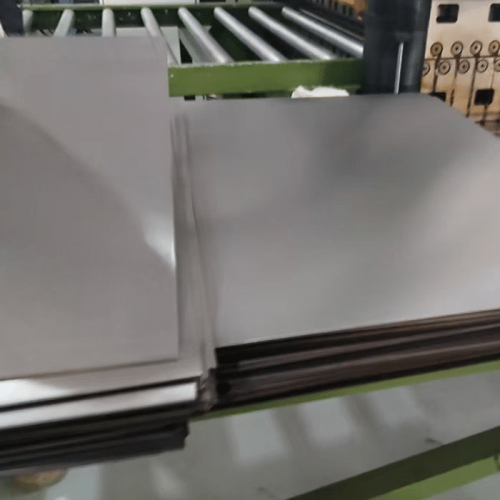

The GH5188 Cobalt Alloy Plate, a high-performance stellite alloy, is engineered for extreme environments. Known for its exceptional strength and corrosion resistance, this cobalt nickel alloy is widely used in aerospace, power generation, and chemical processing. Its unique cobalt alloy composition ensures durability in high-temperature and corrosive conditions, making it a top choice for demanding applications.

China manufacturer offers GH5188 Cobalt Alloy Plate, a high-strength stellite material for aerospace and chemical industries. Exceptional corrosion resistance and durability. Contact us for competitive cobalt alloy pricing.

The GH5188 Cobalt Alloy Plate is critical in industries requiring robust cobalt steel alloys:

| Element | Percentage (%) |

|---|---|

| Cobalt (Co) | Balance |

| Nickel (Ni) | 20-24 |

| Chromium (Cr) | 20-22 |

| Tungsten (W) | 13-15 |

| Iron (Fe) | ≤3 |

| Carbon (C) | 0.05-0.15 |

| Property | Value |

|---|---|

| Tensile Strength | ≥1100 MPa |

| Yield Strength | ≥600 MPa |

| Elongation | ≥20% |

| Hardness | HB 280-350 |

The GH5188 Cobalt Alloy Plate exhibits excellent resistance to acids (e.g., sulfuric and hydrochloric) and alkalis, making it ideal for chemical processing. However, prolonged exposure to highly concentrated oxidizing acids may require additional coatings. This cobalt alloy complies with environmental regulations, with low emissions during manufacturing.

| Environment | Corrosion Rate (mm/year) |

|---|---|

| Atmospheric (Urban) | <0.01 |

| Seawater | 0.02-0.05 |

| Dilute Sulfuric Acid | 0.05-0.1 |

| Hydrochloric Acid (5%) | 0.1-0.2 |

The GH5188 Cobalt Alloy Plate supports multiple welding methods, including TIG, MIG, and plasma arc welding. Preheating to 200°C is recommended to prevent cracking. Forming techniques like bending and rolling are effective, but high forces are required due to the alloy’s strength. Machining requires carbide tools for precision.

The GH5188 Cobalt Alloy Plate exceeded our expectations for turbine blade production. Its heat resistance and durability are unmatched.

John M.

Aerospace Engineer

We’ve used this stellite alloy for reactor linings, and its corrosion resistance has significantly reduced downtime.

Sarah L.

Chemical Plant Manager

The quality and consistency of this cobalt steel from this China factory make it a reliable choice for our gas turbine components.

Michael T.

Procurement Specialist

A: The GH5188 Cobalt Alloy Plate offers a superior balance of heat and corrosion resistance compared to standard stellite materials, with higher nickel content enhancing ductility.

A: Aerospace, power generation, and chemical processing industries rely on its durability in extreme conditions.

A: Yes, it resists moderate concentrations of sulfuric and hydrochloric acids, as shown in corrosion data.

A: The alloy complies with environmental standards, with low levels of restricted substances.

A: Contact our sales team for tailored pricing based on your specifications and order volume.

Professional manufacturer of premium specialty alloys, offering stainless steel, Hastelloy, nickel-based alloys and processing services. Delivering superior metallurgical solutions for aerospace, petrochemical, marine engineering and other demanding industries.