Get in touch with us

Leave a message

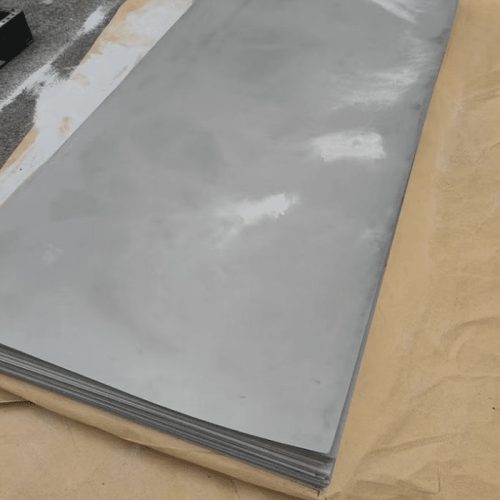

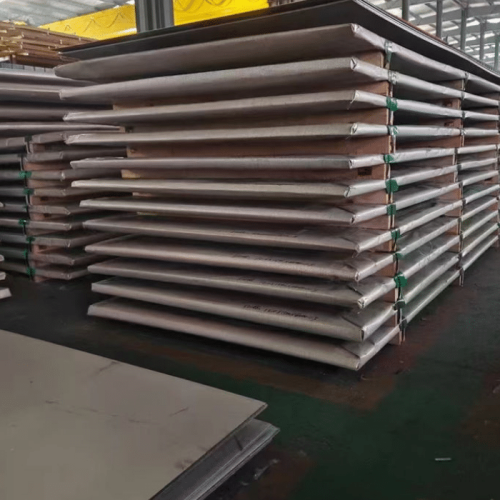

The 1J22 Cobalt Alloy Plate, a high-performance cobalt steel alloy, is engineered for demanding industrial applications. Known for its exceptional magnetic properties and durability, this stellite alloy is widely used in aerospace, electronics, and energy sectors. Its robust cobalt alloy composition ensures reliability in extreme conditions, making it a top choice for manufacturers seeking cobalt alloy uses in precision components.

For competitive pricing and detailed quotes on 1J22 Cobalt Alloy Plate, please contact our sales team through our inquiry form. Pricing terms are tailored based on order volume and specifications.

The 1J22 Cobalt Alloy Plate is utilized across industries, including:

| Element | Percentage (%) |

|---|---|

| Cobalt (Co) | 50.0 - 52.0 |

| Iron (Fe) | Balance |

| Vanadium (V) | 0.5 - 1.5 |

| Nickel (Ni) | 0.2 max |

| Carbon (C) | 0.05 max |

| Property | Value |

|---|---|

| Tensile Strength | ≥ 980 MPa |

| Yield Strength | ≥ 700 MPa |

| Elongation | ≥ 10% |

| Hardness (HB) | 200 - 250 |

The 1J22 Cobalt Alloy Plate exhibits excellent resistance to acids like sulfuric and hydrochloric, as well as alkalis. It complies with environmental restrictions, including RoHS, ensuring minimal ecological impact. However, prolonged exposure to highly oxidizing environments may require protective coatings.

While highly versatile, the 1J22 Cobalt Alloy Plate has limitations:

| Environment | Corrosion Rate (mm/year) |

|---|---|

| Atmospheric (Urban) | < 0.01 |

| Mild Chemical (10% H2SO4) | 0.05 - 0.1 |

| Seawater | 0.02 - 0.05 |

Recommended welding methods include TIG and MIG, with low heat input to prevent cracking. The 1J22 Cobalt Alloy Plate supports forming techniques like bending and rolling. Annealing at 850°C enhances machinability, ensuring precise cobalt alloy uses in manufacturing.

The 1J22 Cobalt Alloy Plate from this China factory exceeded our expectations. Its magnetic properties are perfect for our aircraft components, and the quality is consistent.

John D.

Aerospace Engineer

We’ve been using these cobalt steel alloys for transformer cores. The corrosion resistance and durability are impressive, and the pricing terms are reasonable.

Lisa M.

Electronics Manufacturer

This stellite material is a game-changer for our turbine parts. The fabrication process was smooth, and the support from the manufacturer was top-notch.

Ahmed R.

Energy Sector

A: 1J22 has a unique cobalt alloy composition optimized for high magnetic saturation, unlike other stellite alloys focused on wear resistance.

A: It’s widely used in aerospace, electronics, energy, and medical industries for magnetic and structural components.

A: It performs well up to 500°C, but magnetic properties may weaken beyond this.

A: It’s higher than standard alloys but competitive for its specialized properties.

A: TIG and MIG welding with low heat input are recommended for optimal results.

Professional manufacturer of premium specialty alloys, offering stainless steel, Hastelloy, nickel-based alloys and processing services. Delivering superior metallurgical solutions for aerospace, petrochemical, marine engineering and other demanding industries.