Get in touch with us

Leave a message

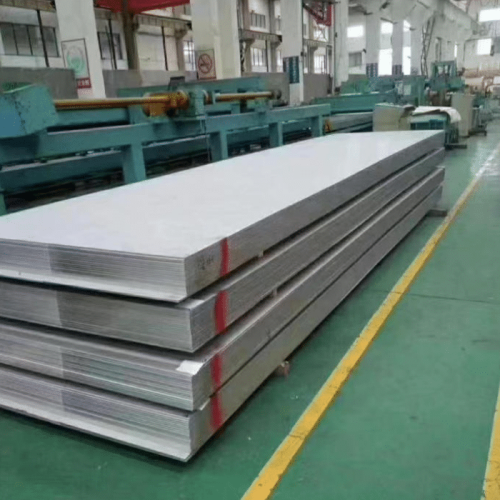

The 3J21 Cobalt Alloy Sheet is a premium cobalt steel alloy designed for high-stress applications. Renowned for its exceptional strength and elasticity, this stellite alloy excels in aerospace, medical, and precision engineering. Its cobalt alloy composition ensures durability and performance in challenging environments, making it a preferred choice for cobalt alloy uses in critical components.

For competitive pricing on 3j21 Cobalt Alloy Sheet, contact our sales team for a personalized quote. Pricing terms are tailored based on order volume and specifications. Reach out today to discuss your needs.

The 3j21 Cobalt Alloy Sheet is versatile, serving industries such as:

| Element | Percentage (%) |

|---|---|

| Cobalt (Co) | 39-41 |

| Nickel (Ni) | 29-31 |

| Iron (Fe) | Balance |

| Chromium (Cr) | 19-21 |

| Molybdenum (Mo) | 1.5-2.5 |

| Carbon (C) | ≤0.05 |

| Property | Value |

|---|---|

| Tensile Strength | 800-1000 MPa |

| Yield Strength | 500-600 MPa |

| Elongation | 20-30% |

| Hardness (HRC) | 30-35 |

The 3j21 Cobalt Alloy Sheet exhibits excellent resistance to acids (e.g., sulfuric and hydrochloric) and alkalis, making it suitable for chemical processing environments. It complies with environmental regulations, with low carbon content ensuring minimal ecological impact.

While highly durable, the 3j21 Cobalt Alloy Sheet has limitations:

| Environment | Corrosion Rate (mm/year) |

|---|---|

| Atmospheric (Urban) | ≤0.01 |

| Mild Chemical (5% NaCl) | ≤0.02 |

| Sulfuric Acid (10%) | 0.05-0.1 |

Recommended welding methods for 3j21 Cobalt Alloy Sheet include TIG and MIG welding, with proper shielding gas to prevent oxidation. Forming techniques such as cold rolling and annealing enhance workability. Precision cutting requires carbide tools due to the alloy’s hardness.

The 3j21 Cobalt Alloy Sheet from this China manufacturer exceeded our expectations for turbine components. Its strength and corrosion resistance are top-notch.

John D.

Aerospace Engineer

We rely on this cobalt steel alloy for surgical implants. The consistent quality and customizable sizes make it a go-to choice.

Li W.

Medical Device Manufacturer

The cobalt alloy properties of this sheet ensure durability in our cutting tools. Great service from the factory!

Emma S.

Industrial Supplier

A: The 3j21 Cobalt Alloy Sheet has a balanced cobalt-nickel composition, offering superior corrosion resistance compared to standard stellite alloys.

A: Aerospace, medical, and industrial sectors leverage its strength and durability.

A: It performs well up to 800°C but may lose efficiency beyond this threshold.

A: TIG and MIG welding are ideal for maintaining the alloy’s integrity.

A: Contact our sales team for tailored pricing based on your specifications and order volume.

Professional manufacturer of premium specialty alloys, offering stainless steel, Hastelloy, nickel-based alloys and processing services. Delivering superior metallurgical solutions for aerospace, petrochemical, marine engineering and other demanding industries.