Get in touch with us

Leave a message

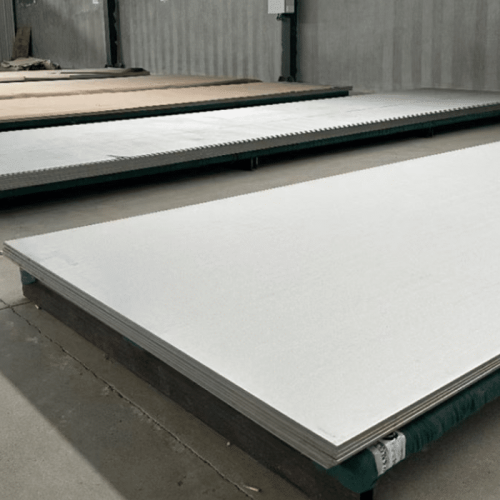

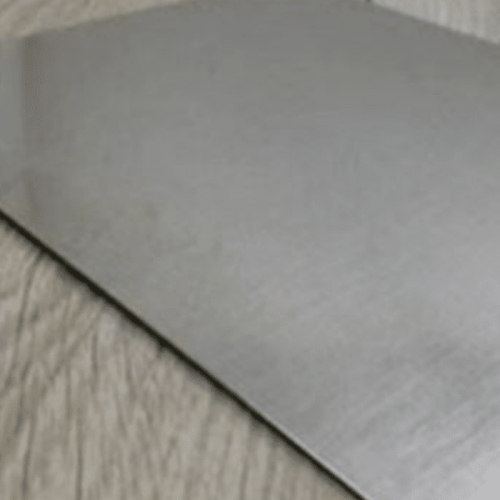

The L605 Cobalt Alloy Plate, a high-performance cobalt-chromium alloy, is renowned for its exceptional strength, corrosion resistance, and durability at elevated temperatures. This cobalt-based alloy is widely used in demanding industries such as aerospace, medical, and power generation, where reliability and performance are critical. Its unique cobalt alloy composition ensures versatility and longevity in extreme environments.

For detailed pricing and customized quotes for the L605 Cobalt Alloy Plate, please contact our sales team. We offer competitive pricing terms tailored to your project requirements, including bulk order discounts and flexible delivery options.

The L605 Cobalt Alloy Plate is utilized across various industries due to its robust cobalt alloy properties. Common applications include:

| Element | Percentage (%) |

|---|---|

| Cobalt (Co) | Balance |

| Chromium (Cr) | 19.0 - 21.0 |

| Nickel (Ni) | 9.0 - 11.0 |

| Tungsten (W) | 14.0 - 16.0 |

| Manganese (Mn) | 1.0 - 2.0 |

| Iron (Fe) | 3.0 max |

| Carbon (C) | 0.05 - 0.15 |

| Property | Value |

|---|---|

| Tensile Strength | 1000 - 1200 MPa |

| Yield Strength (0.2% Offset) | 450 - 600 MPa |

| Elongation | 30 - 40% |

| Hardness (HRC) | 20 - 30 |

The L605 Cobalt Alloy Plate exhibits excellent resistance to acids, alkalis, and oxidative environments. It performs well in sulfuric and hydrochloric acid solutions under moderate conditions. However, prolonged exposure to highly concentrated acids may require additional coatings. The alloy complies with environmental regulations, including RoHS, ensuring safe use in sensitive applications.

| Environment | Corrosion Rate (mm/year) |

|---|---|

| Atmospheric (Urban) | <0.01 |

| Seawater | 0.02 - 0.05 |

| 10% Sulfuric Acid (25°C) | 0.1 - 0.3 |

| 5% Hydrochloric Acid (25°C) | 0.2 - 0.5 |

The L605 Cobalt Alloy Plate supports various welding methods, including TIG (Tungsten Inert Gas), MIG (Metal Inert Gas), and plasma arc welding. Preheating to 200-300°C is recommended to minimize cracking. The alloy can be formed through hot or cold working and machined using carbide tools. For optimal results, consult our technical team for specific fabrication guidelines.

The L605 Cobalt Alloy Plate from this China manufacturer exceeded our expectations for turbine blade production. Its high-temperature strength and corrosion resistance are top-notch.

John D.

Aerospace Engineer

We’ve used this cobalt chrome plate for orthopedic implants, and the biocompatibility is outstanding. The surface finish options make it easy to customize.

Sarah L.

Medical Device Designer

Reliable delivery and consistent quality. The L605 plates have been a game-changer for our chemical processing clients.

Michael T.

Industrial Supplier

A: L605 is a cobalt-chromium alloy optimized for high-temperature strength and biocompatibility, while Stellite alloys are typically harder and used for extreme wear resistance.

A: Aerospace, medical, power generation, and chemical processing industries rely on its durability and corrosion resistance.

A: Yes, it performs well up to 1093°C but may experience creep at prolonged exposure.

A: L605 offers a balanced combination of strength, corrosion resistance, and fabricability, making it versatile for multiple applications.

A: Lead times vary based on order size and customization but typically range from 2-4 weeks. Contact our sales team for details.

Professional manufacturer of premium specialty alloys, offering stainless steel, Hastelloy, nickel-based alloys and processing services. Delivering superior metallurgical solutions for aerospace, petrochemical, marine engineering and other demanding industries.

©2025 alloy-materials.com COPYRIGHT ALL RIGHT RESERVED.