Get in touch with us

Leave a message

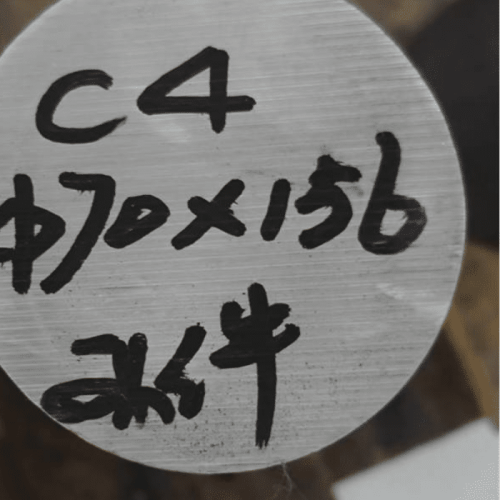

Hastelloy C-4 Pipe, a high-performance nickel-chromium-molybdenum alloy, excels in extreme environments. Known for its exceptional corrosion resistance, this superalloy is ideal for chemical processing and high-temperature applications. As a trusted hastelloy tubing supplier, our China-based enterprise delivers top-quality products globally.

Hastelloy C-4 Pipe pricing is available upon request. Please contact our sales team for a detailed quote, including terms and conditions.

Hastelloy C-4 Pipe is widely used in industries requiring robust corrosion-resistant alloys. Key applications include:

| Element | Percentage (%) |

|---|---|

| Nickel (Ni) | 65.0 min |

| Chromium (Cr) | 14.0 - 18.0 |

| Molybdenum (Mo) | 14.0 - 17.0 |

| Iron (Fe) | 3.0 max |

| Titanium (Ti) | 0.7 max |

| Others | Trace |

| Property | Value |

|---|---|

| Tensile Strength | ≥ 690 MPa |

| Yield Strength | ≥ 283 MPa |

| Elongation | ≥ 40% |

| Hardness | ≤ 100 HRB |

Hastelloy material like C-4 offers excellent resistance to:

While Hastelloy C-4 Pipe is highly durable, avoid using it in:

| Environment | Corrosion Rate (mm/year) |

|---|---|

| Atmospheric | <0.01 |

| 10% Sulfuric Acid | <0.05 |

| 10% Hydrochloric Acid | <0.08 |

Recommended welding methods for Hastelloy metal include:

Fabrication: Cold forming, hot forming, and machining with high-speed tools.

Our chemical plant relies on Hastelloy C-4 Pipe for its unmatched resistance to acidic environments. Delivery from this China manufacturer was prompt!

Judy K.

Chemical Engineer

The quality of these pipes exceeds expectations. Perfect for our high-temperature alloy needs in power generation.

Thomas S.

Project Manager

Great support and competitive Hastelloy pipe price. The pipes perform flawlessly in our marine systems.

Alan Q.

Procurement Officer

A: Hastelloy C-4 Pipe offers superior resistance to both oxidizing and reducing chemicals and has better thermal stability compared to many other alloys.

A: Yes, it performs well in high-temperature applications but should be used below 600°C for optimal performance.

A: It is used across industries such as chemical processing, marine engineering, and waste treatment due to its exceptional corrosion resistance.

A: GTAW, SMAW, and GMAW are the preferred welding techniques for Hastelloy C-4 Pipe to achieve a high-quality weld.

A: Its excellent resistance to chloride-induced pitting and crevice corrosion makes it an ideal choice for seawater applications.

Professional manufacturer of premium specialty alloys, offering stainless steel, Hastelloy, nickel-based alloys and processing services. Delivering superior metallurgical solutions for aerospace, petrochemical, marine engineering and other demanding industries.