Get in touch with us

Leave a message

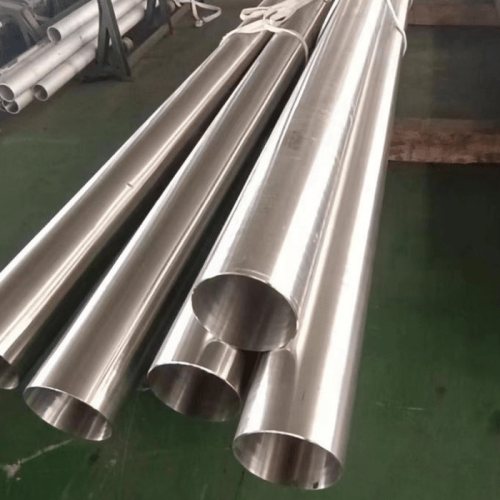

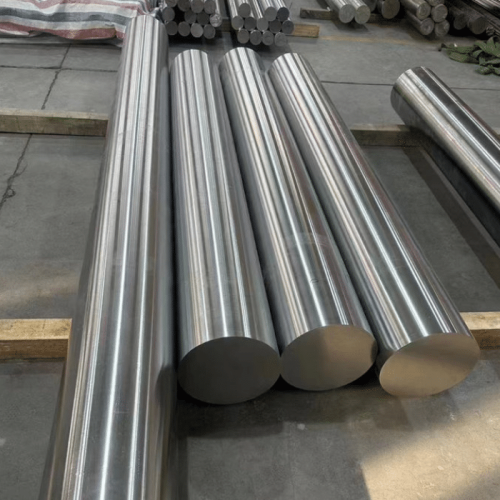

Hastelloy B2 Pipe, a nickel-molybdenum superalloy, excels in extreme chemical environments. Known for its outstanding corrosion resistance, this hastelloy material is ideal for industries requiring durable, high-performance piping solutions. Key applications include chemical processing and pharmaceutical manufacturing.

For competitive hastelloy pipe price, reach out to our sales team for a personalized quote. Pricing terms for Hastelloy B2 Pipe vary based on specifications and order volume.

Hastelloy B2 Pipe is widely used in:

| Element | Percentage (%) |

|---|---|

| Nickel | Balance |

| Molybdenum | 26.0–30.0 |

| Iron | 2.0 max |

| Chromium | 1.0 max |

| Carbon | 0.02 max |

| Silicon | 0.10 max |

| Property | Value |

|---|---|

| Tensile Strength | ≥ 760 MPa |

| Yield Strength | ≥ 350 MPa |

| Elongation | ≥ 40% |

| Hardness | ≤ 95 HRB |

Hastelloy B2 Pipe offers unmatched resistance to hydrochloric acid, sulfuric acid, and other reducing media. It performs well in corrosion-resistant alloys applications but is not recommended for oxidizing environments, as it may corrode under such conditions.

| Environment | Corrosion Rate (mm/year) |

|---|---|

| 10% Hydrochloric Acid (Boiling) | 0.05 |

| 20% Sulfuric Acid (80°C) | 0.1 |

| Atmospheric Exposure | Negligible |

Hastelloy B2 Pipe supports welding via TIG, MIG, and shielded metal arc welding. Preheating is not required, but post-weld heat treatment may be necessary to prevent cracking. Forming techniques include bending and machining, with proper tooling to handle its high strength.

As a hastelloy tubing supplier, we rely on this China manufacturer for consistent quality. Their Hastelloy B2 Pipe performs flawlessly in our chemical processing units.

John D.

Chemical Engineer

The hastelloy composition of these pipes ensures durability in our high-corrosion environment. Highly recommend!

Sarah K.

Plant Manager

Great value for hastelloy price. The pipes exceeded our expectations in sour gas applications.

Mike R.

Oil & Gas Specialist

A: Hastelloy B2 is optimized for reducing environments, while Hastelloy C offers a broader resistance range to oxidizing and reducing agents.

A: Yes, but they are best used under 600°C for structural stability.

A: Yes, they can be tailored to different lengths, thicknesses, and diameters.

A: Common industries include chemical processing, pharmaceuticals, and marine systems.

A: It offers excellent resistance to stress corrosion cracking in aggressive environments.

Professional manufacturer of premium specialty alloys, offering stainless steel, Hastelloy, nickel-based alloys and processing services. Delivering superior metallurgical solutions for aerospace, petrochemical, marine engineering and other demanding industries.