In the construction and automotive worlds, steel is virtually ubiquitous. However, different categories of steel are tailored for specific tasks. In this article, we’ll differentiate non-galvanized steel from galvanized steel, the former being uncoated and the latter coated with zinc. Understanding these differences will help you choose the type of steel that fits with your requirements.

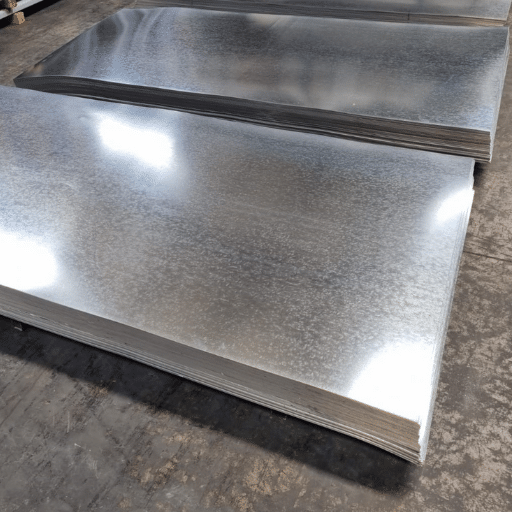

What is Galvanized Steel?

For outdoor construction, galvanized steel with a zinc coating offers unparalleled protective features against moisture and corrosive substances. Unlike non-galvanized steel, the zinc coating allows for prolonged durability, making it a vital part of construction projects. Galvanized steel is frequently needed in construction, fencing, and other projects that require the best performance over a long duration.

Understanding the Galvanizing Process in Detail

The galvanized system is a highly sophisticated method of protecting steel and iron from corrosion. The process begins with preparatory cleaning, which involves removing contaminants like dirt, grease, and other debris that might be stuck on the metal surface. The surface cleaning is done by means of caustic cleaning, pickling, and fluxing. After a thorough cleaning, the metal is dipped into molten zinc baths, which are kept at 840°F (449°C).

While a metal is immersed in zinc, metallurgical reactions occur between the zinc and the iron, creating an alloy layer that bonds firmly to the surface. Steel strengthens due to the vigorous alloying response, which is resistant to corrosive elements and does not incur any physical damage. For the durability of the galvanized layer, accuracy in its thickness is fundamental, usually thinner than a human hair in microns. For example, ASTM A123 dictates that the galvanized zinc coating thickness is 45–85 microns of zinc, depending on the type of steel employed and its application or purpose.

Recent information portrays the effectiveness and eco-friendliness of galvanization. Research indicates that galvanized steel may last over 50 years in rural settings and more than 25 years in coastal and urban areas with moderate upkeep. Moreover, hot-dip galvanization is environmentally friendly because zinc is recyclable and produces very little waste during the process.

This combination of strength, adaptability, and sustainability makes galvanizing critical to many industries, including construction and agricultural machinery manufacturing. Further developments in galvanization technology are improving the process’s efficiency and ecological footprint even more.

The Role of Molten Zinc in Galvanization

The galvanizing process bathed in molten zinc and its casting gives a structural support in surface corrosion damage protection of rub metals, which is losing steel or iron into a kettle of zinc at a temperature of about 840°F (449°C). The interaction between zinc and the steel ensures bond formation on the entire interface, which protects the coating stratum. The following are core attributes and advantages of cyclic zinc in galvanization.

- Prevention of Rust

Rusting and a range of moisture exposure on metals are shielded from by the bond, which excludes oxygen by the layer of zinc rind, which increases bond durability.

- Merchant Services Safety

The previous layer shall also be cut and coated with metal on active sites to repair itself. It’s so that self-mending armor will strengthen for ease of steel closer while apoptosis happens galactic.

- Uniform While Healing And Unprotected Edges

It is submerged in zinc, so Zinc can also form roundamin on all surfaces, especially parts where contamination from scratches during exposure takes place on edges and corners. We offer full stratum Shield.

- Strong Protection

For long-prosed metals maintenance in shipping and construction, the duration is prolonged for several with minerals mating copper. Galvan was level with super surpasses He’s so claim durable deepest in rusty constructions at a time decades in.

- Benefits to the Environment

The galvanization method produces little waste, and zinc can be recycled completely. This characteristic of zinc galvanization aligns with contemporary environmental criteria and helps industries become greener.

Advantages of Using Galvanized Steel

| Key Advantage | Description |

|---|---|

| Cost-Effective | Lower initial and long-term costs. |

| Durability | Resistant to mechanical damage and corrosion. |

| Long Life Expectancy | Lasts 50+ years in rural, 20+ in harsh areas. |

| Low Maintenance | Requires minimal upkeep over time. |

| Complete Protection | Covers all areas, including corners and recesses. |

| Rust Resistance | Zinc coating prevents rust effectively. |

| Automatic Damage Repair | Zinc protects exposed steel areas. |

| Ease of Inspection | Simple visual and non-destructive checks. |

| Fast Installation | Ready-to-use, no extra preparation needed. |

| Weather-Independent | Can be applied in any weather conditions. |

What is Non-Galvanized Steel?

Non-galvanized steel refers to steel that has not been covered with a protective zinc coating. Unlike non-galvanized steel, it does not have corrosion resistance from rust and the environment. This type of steel may be cheaper to begin with, but it is prone to needing constant maintenance to prolong its lifespan when exposed to moisture. Non-galvanized steel is usually employed indoors or in areas where there are minimal concerns over rust.

Characteristics of Non-Galvanized Steel

Compared to other metals, non-galvanized steel has unique traits that make it ideal for application in specific environments where no moisture or harsh conditions are expected. Below are some key details and data about non-galvanized steel:

- Material Composition

As the name suggests, non-galvanized steel lacks a protective coating of any galvanic material. This leaves it with a composition of iron and carbon, which makes it more prone to rotting.

- Strength and Durability

Steel has very high tensile strength in its raw state, which is undoubtedly helpful for its primary use in structures. Its use in construction is prevalent where it is used indoors along with machines and tools not prone to needing corrosion resistant materials.Corrosion Susceptibility

- Corrosion Susceptibility

Non-galvanized steel’s major downside is not its best feature. Because it does not have zinc or a protective coating, it is susceptible to moisture, which leads to rust. It also needs unending maintenance efforts, like painting and applying sealants.

- Affordability

Compared to galvanized steel, non-galvanized steel tends to be rather affordable. Despite the low initial cost, additional maintenance and replacement further increase the overall value, making it less economical for some purposes in the long run.

- Applications and Usage Data

Construction sector: Non-galvanized is popular in the construction industry for beams, columns, and reinforcements as long as the area is sheltered from rain and high humidity.

Automotive and Machinery: Non-galvanized steel can also be found in internal, enclosed engine parts and other equipment shielded from direct contact with the external environment.

- Environmental Limitations

Industry data shows that raw steel can corrode in two to three weeks in environments with high humidity. Non-galvanized steel’s lifespan can be significantly shortened when used outdoors without a protective coating.

Non-galvanized steel is ideal for situations where its strength and price need to be balanced against exposure to corrosive elements, as regular inspection and maintenance are also needed.

Common Applications of Plain Steel

| Application Area | Description |

|---|---|

| Construction | Beams, columns, and reinforcing bars. |

| Automotive | Car bodies, chassis, and gears. |

| Machinery | Machine parts, tools, and equipment. |

| Consumer Goods | Cookware, appliances, and utensils. |

| Railways | Tracks and other durable components. |

| Agriculture | Farming tools and equipment. |

| Tool Making | Hand tools and cutting instruments. |

| Pipelines | Fluid transport systems and tubing. |

| Electrical Wiring | Wiring and high-strength cables. |

| Forgings | Gears, shafts, and heavy-duty parts. |

Limitations and Corrosion Concerns

Plain steel’s major drawback is its susceptibility to rust in moist or chemically active environments, which requires protective coatings or treatments for prolonged use.

Differences Between Galvanized and Non-Galvanized Steel

The most distinct characteristic that sets apart galvanized steel and its non-galvanized counterpart is the level of corrosion resistance. Coated with zinc, galvanized steel is able to withstand rust and corrosion in wet environments, making it more durable and suitable for outdoor and high humidity activities as compared to its counterpart.

Non-galvanized steel lacks this coating, making it more likely to rust under moist or corrosive conditions. While often cheaper than galvanized steel, it still incurs more expenses due to the extra treatments or coatings needed to survive harsh conditions.

The two options can be chosen depending on one’s needs, as non-galvanized is suited for short-term projects while the latter is best for long-term durability and resistance to corrosion.

Corrosion Resistance and Durability

I would select galvanized steel where protecting against metal erosion and warping is an issue, as the galvanized zinc coating offers resilience against rust and other destructive elements. The coating increases corrosion resistance, ensuring longevity while reducing maintenance costs, which is beneficial in harsh environments. On the other hand, untreated steel may be beneficial in noncritical environments if cost is of primary concern, as long as the right protective steps are utilized.

Cost Considerations for Galvanized vs Non-Galvanized Options

| Aspect | Galvanized Steel | Non-Galvanized Steel |

|---|---|---|

| Initial Cost | Minimal overtime. | Lower upfront cost. |

| Maintenance Cost | Minimal over time. | Requires frequent maintenance. |

| Lifespan | 50+ years in most environments. | Shorter lifespan, prone to rust. |

| Corrosion Resistance | Excellent due to zinc coating. | Poor, needs additional protection. |

| Long-Term Cost | Lower due to durability. | Higher due to repairs and replacements. |

| Environmental Impact | Sustainable, recyclable zinc coating. | Higher due to frequent replacements. |

| Application Time | Requires additional processing time. | Ready for use immediately. |

| Durability | High, withstands harsh conditions. | Lower, vulnerable to damage. |

Structural Integrity and Protection

The exceptional coating that defends against corrosion makes galvanized steel one of a kind in terms of its structural integrity and protection capabilities. Here are five detailed points that talk about the benefits of galvanized steel regarding it’s structural strength and durability:

- Corrosion Resistance

Due to the zinc coating applied on top, moisture and oxygen cannot freely reach the underlying steel, meaning that the barrier successfully maintains corrosive elements. This dramatically decreases the chances of rust formation over time.

- Enhanced Longevity

Structures made with builit galvanized steel can exist for over 50 years within typical environments, and in rural places where pollution levels are low, it’s even longer.

- Strength Under Stress

Along with extreme humidity, rainfall, and salt-laden coastal air, galvanized steel maintains structural capabilities during several other environmental variations.

- Low Maintenance Requirements

The protective layer decreases the frequency of inspections and repairs that need to be carried out, which increases the asset’s life span by reducing needed downtime.

- Impact Resistant

Zinc adds a new layer of mechanical protection, making the steel resistant to scratches, dents, and all sorts of damage that can potentially harm its structural integrity.

How does Corrosion Affect Steel?

Steel corrosion weakens its structure and reduces its lifespan. Steel reacts, forming rust, which deteriorates the material when exposed to moisture and oxygen over time. This process modifies the material’s decay rate, compromising the steel’s strength, rendering it less reliable for use in mechanical or structural applications. In harsh environments, corroded steel could increase maintenance costs alongside frequent replacements. Protective measures against corrosion ensure steel durability and performance.

Factors Contributing to Rust Formation

The formation of rust occurs because of the oxidation processes triggered by hydrogen, oxygen, and water. Certain environments also accelerate oxidation. The humidity or saltwater exposure for a prolonged period significantly enhances the rate of rust development. Areas near the coast are reported to have oxidation rates 10 times higher due to salt particle exposure in the air compared to areas inland.

Ignoring the role of pH or temperature levels is not an option. Steel becomes more susceptible to corrosion in a highly acidic environment caused by acid rain. Moreover, expansion induced by temperature changes can lead to contraction and the creation of micro-cracks within steel. These micro-cracks allow moisture to penetrate, aiding rust.

Latest Data on Steel Corrosion

The economic consequences of corrosion are valued at over $2.5 trillion per year, representing an astounding 3-4% of global GDP. Effective corrosion control and corrosion prevention techniques, utilizing protected exponent shields, reactive alloys, and cathodic shielding systems, stand to reduce industrial corrosion costs by 30% year on year.

Coatings designed to self-repair and embedded with corrosion-limiting agents have demonstrated remarkable efficacy during laboratory assessments. Such coatings serve the dual purpose of corrosion prevention and steel longevity. By releasing inhibitors at damaged sites, these watertight seals locked around steel constructions halt corrosion progress.

Rethinking the underlying principles and mechanisms behind corrosion allows industries to unlock innovative approaches and strategies to reduce injury to left infrastructure and significantly improve public safety and the resilience of steel infrastructure.

The Importance of Protective Zinc Layers

| Key Aspect | Description |

|---|---|

| Corrosion Resistance | Shields metal from rust and environmental damage. |

| Sacrificial Protection | Shield metal from rust and environmental damage. |

| Barrier Protection | Prevents moisture and oxygen from reaching metal. |

| Extended Lifespan | Zinc corrodes first, protecting the base metal. |

| Self-Healing | Repairs minor scratches via galvanic action. |

| Cost-Effectiveness | Reduces maintenance and replacement costs. |

| Environmental Benefits | Zinc is recyclable and sustainable. |

| Versatility | Suitable for various shapes and applications. |

| Aesthetic Appeal | Provides a sleek, uniform finish. |

| Heat Reflection | Reduces heat absorption in specific coatings. |

Impact on Structural Steel and Steel Products

Understanding the challenges exacerbated by the aggressive nature of rust on steel drives home the importance of properly managing and controlling corrosion. Corrosion dulls the edges of life and diverges in movement from the expected direction. Texas trim and other protective coatings, while voiding form benign voicemail foils, bring practical solutions to corrosion, effectively ensuring functionality and helping dramatically reduce dull edges and absorb costs.

When to Choose Galvanized vs Non-Galvanized Steel?

| Criteria | Galvanized Steel | Non-Galvanized Steel |

|---|---|---|

| Corrosion Resistance | Ideal for humid, salty, or outdoor environments. | Suitable for dry, indoor applications. |

| Durability | Long-lasting with minimal maintenance. | Requires frequent maintenance to prevent rust. |

| Cost | Higher upfront, lower long-term costs. | Lower upfront, higher maintenance costs. |

| Heat Resistance | Not suitable for high-temperature applications. | Suitable for high-heat environments. |

| Aesthetic Needs | Spangled or smooth zinc finish. | Offers diverse finishes and textures. |

| Welding | Requires zinc removal before welding. | Easier to weld without extra preparation. |

| Weight | Slightly heavier due to zinc coating. | Lighter, depending on steel type. |

| Applications | Outdoor structures, automotive, and agriculture. | Indoor machinery, tools, and decorative uses. |

| Environmental Impact | Sustainable and recyclable zinc coating. | Requires more frequent replacements. |

Considerations for Outdoor vs Indoor Use

While a decision regarding using galvanized and non-galvanized steel is critical, the factors that affect the environment also hold equal importance. The following are five pointers to get you started:

- Exposure to Moisture:

- Steel is subject to rain, humidity, and other moisture sources in outdoor conditions, which can lead to corrosion. Since galvanized steel has a protective zinc coating, it does not rust and is, therefore, preferred for outdoor use.

- Non-galvanized steel is a suitable and economical option for indoor environments that are not exposed to moisture.

- Temperature Fluctuations:

- Non-galvanized steel can withstand extreme temperature changes, expansion, and contraction. This is not the case for non-galvanized steel, which starts losing structural integrity under such changes.

- For indoor use non-galvanized steel is a reasonable option due to less extreme temperature fluctuations.

- Durability Requirements:

- Fences, bridges, and roofing materials are outdoor steel structures that are subjected to harsh wind and ultraviolet exposure. In this case, galvanized steel comes in handy since it is built to last.

- Understated indoor applications, such as furniture and even storage racks, do not call for using galvanized steel.

- Aesthetic Considerations

- The finish of galvanized steel is often dull and metallic, which blends well with functional designs for the outdoors. However, overlooking visual appeal may result in using painted or coated steel.

- Non-galvanized steel has more flexibility with paint and treatment options, allowing for easier custom designs suited for specific indoor applications.

- Cost Efficiency

- Though galvanized steel has a higher upfront cost than other options, its rust resistance saves money over time on maintenance in outdoor settings.

- Non-galvanized steel is the most budget-friendly option for indoor use where risk of corrosion is low, making it more economical than other materials.

Assessing Environmental Factors

When choosing between galvanized and non-galvanized steel, their environmental considerations is one of the factors to analyze regarding the long-term usefulness and cost-efficiency of the material. For example, in applications concerning construction, galvanized steel is more useful in highly humid settings, saltwater exposure, or when the steel is used in outdoor constructions where it is likely to undergo severe weathering or corrosion. It’s been observed that protective galvanized coatings will add an average 50 years to the lifespan of steel in rural regions and 20-25 years in industrialized or coastal areas. Thus, it is ideal for maritime structures, outdoor railings, and bridges.

On the contrary, non-galvanized steel can also work perfectly in controlled indoor environments devoid of moisture or any corrosive influence, making it much cheaper. Research suggests that internal application of non-galvanized steel presents a far lesser risk of surface rusting as long as the environment remains temperature-controlled, coupled with low humidity, and sealed. The same applies to other materials, where the most important features like pollution, climate, and intended purpose dictate the material’s performance and expenses throughout its lifetime.

Another factor is environmental friendliness. Galvanized steel coatings are materials that help lower the carbon footprint of long-term usages since the coating itself can be recycled. This emission of pollution, which galvanization coverings can assist in, encourages an increase in materials that are meant for and effectively combine performance with environmental conservation.

Choosing Based on Project Requirements

While selecting materials for a project, I pay extra attention to how the material aligns with the hurdles posed by the project. For example, I evaluate factors such as environmental exposure and economy. Moreover, I emphasize sustainability and try to incorporate recyclable galvanized steel coatings so that the project is as efficient as it is eco-friendly. All these factors allow me to balance performance, longevity, and environmental impact.

References

- Galvanized or Painted Steel Fence Posts – Open PRAIRIE – A study on the durability and rusting of galvanized posts over time.

- How Zinc Metal Coatings, Including Hot-Dip Galvanizing, Protect Steel – A detailed document on the protective properties of zinc coatings, including galvanization.

- Effect of the Galvanization Process on the Fatigue Life of High-Strength Steel – A study comparing the fatigue life of galvanized and non-galvanized steel.

Frequently Asked Questions (FAQ)

Q: What is the main difference between galvanized and non-galvanized steel?

A: The main difference between galvanized and non-galvanized steel is the presence of a protective zinc coating on galvanized steel. This coating helps resist corrosion and extends the lifespan of the steel, making it ideal for outdoor applications.

Q: How does the galvanizing process work?

A: The galvanizing process involves immersing the metal in a bath of molten zinc, creating a protective layer of zinc that bonds with the underlying steel. This hot-dip method forms a durable barrier that protects against corrosive elements.

Q: Why is galvanized steel more corrosion resistant?

A: Galvanized steel is more corrosion resistant due to its protective zinc coating. The zinc acts as a sacrificial layer, corroding first and protecting the underlying steel from exposure to moisture and corrosive environments.

Q: Are there different types of galvanized steel?

A: Yes, there are different types of galvanized steel, including hot-dip galvanized and electro-galvanized. Hot-dip galvanized steel is often used for outdoor applications due to its thicker zinc coating, while electro-galvanized steel has a thinner layer applied through an electrical process.

Q: Can galvanized steel be welded safely?

A: Welding galvanized steel requires special precautions due to the zinc coating, which can release toxic fumes when heated. Proper ventilation and protective gear are essential to ensure safety when welding galvanized steel parts.

Q: What are common uses for galvanized steel?

A: Galvanized steel is often used in construction, automotive, and agriculture industries for roofs, fasteners, and galvanized bolts. Its low maintenance and durability make it suitable for outdoor applications where corrosion resistance is crucial.

Q: Is non-galvanized steel suitable for outdoor use?

A: Non-galvanized steel isn’t typically suitable for outdoor use because it lacks the protective zinc coating that helps resist corrosion. Unless treated with other protective coatings, it is more prone to rust and deterioration, especially in corrosive environments.

Q: How does the cost of galvanized steel compare to non-galvanized steel?

A: Galvanized steel generally costs more than non-galvanized steel due to the additional processing required to apply the protective zinc coating. However, its durability and corrosion resistance can lead to long-term savings in maintenance and replacement costs.

Q: Does the steel grade affect the galvanizing process?

A: Yes, the steel grade can affect the galvanizing process. Different steel grades may react differently during the hot-dip process, influencing the thickness and uniformity of the zinc coating.