Get in touch with us

Leave a message

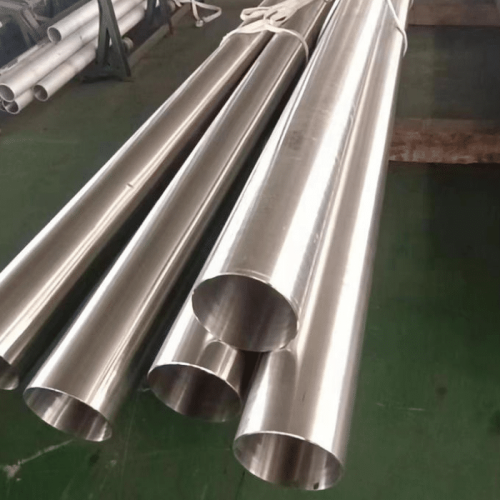

The TA3 Titanium Alloy Bar is a high-strength, lightweight material designed for demanding industrial applications. Renowned for its excellent corrosion resistance and superior mechanical properties, this alloy is ideal for aerospace, medical implants, and marine industries. Its unique composition ensures reliability and performance in extreme environments, making it a sought-after choice for engineering professionals.

The price of the TA3 Titanium Alloy Bar varies based on specifications and order quantity. Please contact us directly for a quote. Pricing terms are available upon request.

| Element | Percentage (%) |

|---|---|

| Titanium (Ti) | Balance |

| Iron (Fe) | ≤0.30 |

| Carbon (C) | ≤0.08 |

| Nitrogen (N) | ≤0.05 |

| Hydrogen (H) | ≤0.015 |

| Oxygen (O) | ≤0.35 |

| Property | Value |

|---|---|

| Tensile Strength | ≥500 MPa |

| Yield Strength | ≥380 MPa |

| Elongation | ≥18% |

| Hardness (HB) | ≤200 |

TA3 exhibits exceptional resistance to both acidic and alkaline environments. It performs optimally in chloride-rich conditions and is suited for seawater applications while maintaining stability under extreme environmental constraints.

| Environment | Corrosion Rate |

|---|---|

| Atmospheric (Rural) | Negligible |

| Seawater | <0.01 mm/year |

| 10% Nitric Acid | <0.05 mm/year |

| 10% Sulfuric Acid | Not recommended |

Contact us for detailed corrosion resistance data specific to your application.

TA3 Titanium Alloy Bar is well-suited for TIG and MIG welding methods. Optimal practices include maintaining a clean work area to prevent contamination and using inert gases like argon or helium. It is also conducive to cold forming and CNC machining.

These TA3 bars are perfect for our lightweight structural needs. Reliable quality from this China manufacturer.

Tina Q.

Aerospace Engineer

The biocompatibility of this titanium alloy is top-notch for our implants. Consistent delivery.

Vincent J.

Medical Supplier

Excellent corrosion resistance in seawater. Our offshore projects depend on these titanium rods.

Andy P.

Marine Contractor

Professional manufacturer of premium specialty alloys, offering stainless steel, Hastelloy, nickel-based alloys and processing services. Delivering superior metallurgical solutions for aerospace, petrochemical, marine engineering and other demanding industries.