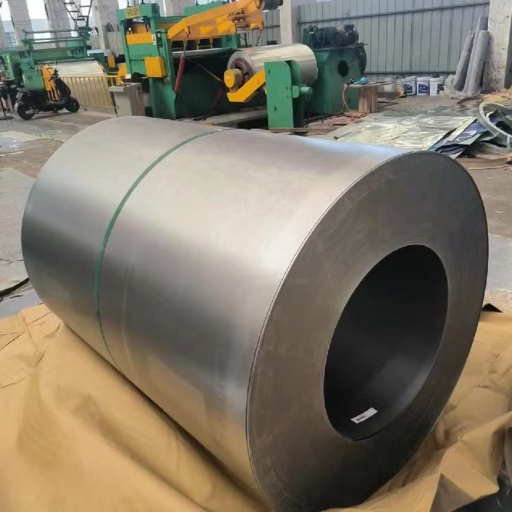

Discuss sturdy and multifunctional raw materials suitable for building and fabricating technologies. I think steel material that comes out on top in most industrial uses is the S220G galvanized instrumental steel coil. This hard-wearing product finds favor with many because it possesses desirable qualities such as high stress strength and resistance to rust and solvents, which is why you can easily find it in use within various processes, from the construction of roofs to that of vehicles. However, what makes the S220GD galvanized steel coil special, and how can this product effectively cope with the challenges of the contemporary world? In what follows, I will identify the critical characteristics of galvanized ( S220) material and extend it to many possible areas where it can be utilized. The potential of s220gd coil use is helpful once you are in construction, production, and supply. Take your time and read on to understand how this resourceful construction material will revolutionize your business.

What is S220GD Galvanized Steel Coil?

A type of steel known for its tensile strength and that undergoes galvanization is called S220GD galvanized steel coil. The spirals won’t corrode when kept open due to this extended layer of zinc protection applied to the surface of the coil’s steel. S220GD is a material used primarily in construction, the automotive industry, and the production industry, among others, due to its optimized strength, ease of manipulation, and cost. It meets all incoming demands on the perfect quality, hence it can be used for applications where the material… has to be high performing and durable.

Definition and Characteristics of S220GD

S220 GD primarily refers to structural steel with high load-bearing capability. It is most often found in the galvanized design used in the building and industrial sectors. Its significant advantages are excellent physical properties, durability, and compatibility with various coating methods, including hot dip galvanizing for extra corrosion protection.

Chemical Composition

S220GD was designed with a specific range of alloying elements to impart it a particular combination of mechanical properties and capability. The chemical analysis of steel S220GD can be expressed as:

- Carbon (C): max 0.20%

- Manganese (Mn): max 1.70%

- Silicon (Si): max 0.60%

- Phosphorus (P): max 0.10%

- Sulfur (S): max 0.045%

- Nitosiren (N): max 0.012%

Such chemical specifications maintain the steel’s structural integrity, allowing for adequate flexibility, weldability, and inbuilt corrosion resistance.

Mechanical Properties

Mechanical properties present in S220GD are helpful in the understanding of its strength as well as elasticity :

- Yield Strength (Re): 220 MPa minimum

- Tensile Strength (Rm): 300 – 400 Mpa

- Elongation at Break (A80): 24% minimum

- Thickness: Usually, it is supplied in sizes ranging from 0.20 mm to 4.00 mm.

These ratings of moderate tensile and elastic strength make S220 GD easily bendable, shapeable, and formable without any issues with structural rigidity.

Galvanisation and Resistance to Corrosion:

A distinctive feature of S220GD is that it is best recommended for galvanization. Such a process implies the application of a substance containing zinc on the steel, which serves as a barrier against the penetration of water and air. S220GD steel is usually produced with a zinc coating “Z” ranging from Z100 to Z600, which means the higher the number, the bigger the protection against corrosion in terms of corrosion steel.

Uses:

Due to its moderate strength, flexibility, and price, S220 GD is applied in the manufacturing industry as well as in the following;

- Buildings: Roofs and walls, light steel sections, and construction elements

- Grammes: For making parts ofthe chassis and the under surfaces

- White-goods- Cooking utensils, domestic tanks, storage tanks and semi-trailer cars

Main advantages

- Protection against rust: coats the surface with zinc for a longer life and less maintenance.

- Plasticity and weldability: There is no difficulty in forming and welding this steel while fabricating structures.

- Affordability: At an affordable cost, it provides high output.

- Standards: S220GD complies with EN 10346 standards, providing high-quality products.

These characteristics make S220GD a perfect steel state for industries that require rigid yet flexible materials.

Applications of S220GD Galvanized Steel Coil

| Application Area | Key Uses |

|---|---|

| Construction | Roofing, wall cladding, structural panels |

| Automotive | Body panels, reinforcements, undercarriage parts |

| HVAC Systems | Ventilation ducts, exhaust systems |

| Consumer Appliances | Washing machines, refrigerators, oven liners |

| Industrial Equipment | Storage tanks, agricultural machinery parts |

| Electrical Equipment | Enclosures, transformer casings |

| Furniture | Cabinet frames, shelving systems |

| Solar Energy | Mounting systems, solar panel structures |

Comparison with Other Steel Grades

Comparing the S220GD coil to other types of steel, one should consider all specifics such as strength, formability, resistance to corrosion, and cost-effectiveness. The following are 5 steel grades against which the S220GD is compared to underscore its advantages:

- S250GD

- Tensile Strength: It is stronger than S220GD (around 250 MPa at minimum).

- Formability: It is less ductile than S220GD.

- Corrosion Resistance: It is roughly equivalent to S220GD since the zinc coating technology is also applied.

- Cost: It costs a bit more since the strength is upgraded.

- Applications: This steel is primarily used for structures and finished products that are heavier than S220GD components.

- S350GD

- Tensile Strength: Much higher (350 MPa minimum) and as such can be used as structural components.

- Formability: The steel is less formable than S220GD due to its high strength.

- Corrosion Resistance: A similar zinc coating process offers adequate corrosion protection.

- Cost: It is more expensive than the others because it performs better.

- Applications: As the name implies, this steel is often employed in strong frames and heavy-duty settings.

- DX51D

- Tensile Strength: Similar to typical ranges of 270 to 500 MPa based on condition.

- Formability: This is similar to or more than S220GD, which makes it suitable for complex formations.

- Corrosion Resistance: Close to the levels of zinc coating adhered.

- Cost: Slightly more when there is a thicker coating.

- Applications: In cases where coil is used in household electronics, automotive assembly, and the building of lightweight structures.

- DX52D

- Tensile Strength: Slightly greater but also with enhanced elongation for deep draw capability.

- Formability: Better than S220GD because deeper shapes and drawing operations can be carried out.

- Corrosion Resistance: Sufficient corrosion protection is provided as a requirement.

- Cost: Expensive due to the superior formability and elongation characteristics.

- Applications: Used for car panels, precision decorative components, and design elements.

- DC01 (Cold Rolled Steel)

- Tensile Strength: It is not as good as S220GD but offers superior uniformity in thickness.

- Formability: Better due to its cold-rolled manufacturing.

- Corrosion Resistance: Unless coated, this is not good as the steel does not have any level of galvanization, unlike S220GD.

- Cost: Less for specific applications that do not require additional coatings.

- Applications: This type of steel is used where a clean and formable surface is essential, such as in the construction of vehicles and furniture.

These examples clearly show that S220GD can be used in many applications because of its diverse performance. For certain projects, selecting other types of steel can be advantageous based on their special properties, strength, or cost.

How is the Coating Applied to S220GD?

A Hot Dip Galvanizing Process is used whereby a molten zinc bath is dipped into a s220gd coil to obtain the raised surface protection. There is a perpetual coating film bonded on the steel surface to prevent corrosion. It ensures the long-term stability of the steel, which can be used for various purposes. This can be given because the process effectively provides an even coating on the steel with good adhesion.

Types of Coating for Galvanized Steel Coil

| Coating Type | Key Features |

|---|---|

| Hot-Dipped Galvanized | Zinc coating for corrosion resistance |

| Galvannealed | Zinc-iron alloy, paintable, matte finish |

| Galvalume | Aluminum-zinc alloy, superior corrosion resistance |

| Electro-Galvanized | Thin zinc layer, smooth surface, paintable |

| Powder Coating | Durable, uniform, environmentally friendly |

| Acrylic Systems | UV-resistant, suitable for interior applications |

| Epoxy Coatings | Tough, chemical-resistant, needs UV topcoat |

| Polyester Coatings | UV-resistant, ideal for outdoor use |

| Plastisol Coatings | Thick, durable, weather-resistant |

| Zinc-Rich Primers | High corrosion protection, used for repairs |

Hot-Dip Galvanizing Process

Steel becomes corrosion resistant through a process called hot-dip galvanization, which entails dipping it in a solution of zinc. Recent developments in the building and industrial sectors still demand the same process, which offers lifetime protection while being wallet-friendly.

Importance of Zinc in Corrosion Resistance

The use of zinc is significant in preventing steel from corrosion, where it acts as a protective and sacrificial layer. Under identical conditions and at an equal respective thickness, the corrosion rate of zinc is far below that of ferrous alloys, thus offering a considerable service life of the substrate. New evidence suggests that galvanized coatings that contain zinc components allow increasing the length of service of steel constructions in some environments to 50 years and even more.

As per the International Zinc Association, over half of the total zinc produced worldwide is consumed for corrosion resistance. Zinc provides this function in three different ways – by providing barrier protection through formation of a thick film, by providing cathodic protection where zinc is a sacrificial layer to the steel underneath when the coat is removed, and by giving a corrosion resistance through formation of a zinc patina which retards the process of corrosion.

For industries like construction, automotive, and infrastructure, zinc is an element that enhances the life span of the products used in those industries. For Example, in construction works, roofing materials, industrial sheds, and signboards all use galvanized s220gd coil, such that all these structures have a longer service life even during adverse weather conditions. Moreover, according to the market survey 2023, the demand for galvanized steel is growing relatively. It is expected to grow with a compound annual growth rate (CAGR) of 5.7% by the end of 2030, which is in demand for economical and durable materials.

Zinc is used in efforts to support green growth policies. All zinc coatings are recyclable, and their durability reduces the amount of material needing replacement, thereby conserving resources. Thus, zinc-coated steel is environmentally acceptable for modern manufacturing and construction.

What are the Specifications of S220GD Galvanized Steel Coil?

Extra tough, s220gd coil steel is also galvanized, making it exceptionally resilient to damage after intensive utilization. The specs for the coil are as follows:

- Quality: Steel coil grade S220GD

- Tensile Limit of Elasticity: Not less than 220 MPa

- Type of Coated Mild Steel: Galvanizing of a mild steel sheet for anti-corrosion

- Amount of Galvanism: 60–600 g/m² approximately, depending on the Purpose

- Thickness Availability – minimum 0.3 mm up to 3.0 mm thick

- Width Availability – Up to 1250 mm

- Texture – Common Spangle, Zero Spangle, and Case Hardening

- Ductility – Ease in forming, bending and rolling in addition to other operations

The above features make the s220gd coil ideal for building engineering, automobile, and production sectors.

Chemical Composition of S220GD

However, the chemical formula of all steels does not belong to a randomly defined class; instead, it is strictly limited by standards to guarantee the performance and service of galvanized or otherwise coated steels, particularly s220gd coils. Here is a summary of the most important chemical elements present in it:

- Carbon (C) ≤ 0.20%

- Silicon (Si) ≤ 0.60%

- Manganese (Mn) ≤ 1.70%

- Phosphorus (P) ≤ 0.10%

- Sulphur (S) ≤ 0.045%

- Aluminium (Al) ≥ 0.015%

The limitations given above provide the production with exceptional attributes such as mechanical properties, resistance to corrosion, and the ability to coat the surface easily.

In fact, the limits characterizing such a chemical in s220gd coil perfectly meet a balance between a product’s durability and the ductility required in businesses where high deformations of certain materials are integrated with significant loads. In this case, if such a structure is applied, the chemicals, when enhanced by specified galvanization methods, exhibit performance for a longevity that is fit enough for extreme conditions such as the outdoors or inside an automobile.

Mechanical Properties and Yield Strength

| Property | Details |

|---|---|

| Yield Strength | Minimum 220 MPa |

| Tensile Strength | 300-430 MPa |

| Elongation (A80) | Minimum 20% |

| Thickness Range | 0.4-4.0 mm |

| Width Range | Up to 2,020 mm |

| Hardness | Soft to medium, depends on processing |

| Corrosion Resistance | High, due to zinc coating |

| Applications | Construction, automotive, appliances |

Industry Standards: ASTM, JIS, and DIN

| Standard | Description |

|---|---|

| ASTM A653M | American standard for galvanized steel |

| JIS G3302 | Japanese standard for galvanized steel |

| DIN 17162 | German standard for galvanized steel |

| EN 10327 | European standard for continuous hot-dip steel |

| EN 10142 | European standard for structural applications |

| EN 10147 | European standard for construction purposes |

| EN 10292 | European standard for high-strength steel |

How to Ensure Quality and Adhesion in S220GD?

The following requirements should be adhered to when working with S220GD to be of acceptable quality and adhesion:

- Surface Preparation: Ensure that the working area is cleaned as thoroughly as possible by removing any foreign bodies, such as oils, greasy substances, or powder, that may prohibit the adhesion process.

- Proper Coating Application: To protect the zinc coating, which is a crucial material factor as it prevents rusting, correct procedures should be followed, and even distribution should be attained.

- Controlled Environment: Appropriate means should be used to regulate welding, cutting, or forming without compromising the quality of the material.

- Quality Inspections: Ensure that the material is inspected regularly for defects such as cracks or uneven coating to meet various industry requirements, such as ASTM, JIS, and DIN.

- Testing for Adhesion: Adhesion tests should be carried out based on applicable industry standards to ascertain that the applied coatings will endure the programmed conditions.

- Proper Storage: Store S220GD in a cool and dry place and well-ventilated to avoid exposure to water contact and corrosion causes.

Implementing these practices ensures that S220GD meets the required performance in application areas such as construction, automotive, and appliances.

Surface Treatment and Passivation

Surface treatment and passivation are key processes that enhance the service life and corrosion resistance of the S220GD grade. This is consistent with the user’s search for materials that need to be strong and last longer.

Testing for Surface Quality and Adhesion

It is crucial to check the surface quality and adhesion of the s220gd coil to ensure its strength and robustness for some of its intended uses. Various sophisticated diagnostic procedures are used to evaluate how specifications in terms of finish and even bonding build up on materials to be covered with finishes. The essence of the performance of the material is dependent on the behavior of the coating layer; thus, such tests are intended to ensure that the coating layer is void of any defects, such as microcracks, voids, wrong thickness, and so on.

While performing a bend test on this surface, the sample is flexed in different angles to check the extent of coat bonding to the substrate. Results show how much the coat retains or comes off the supporting surface during bending. It is noted from the most recent research in the field of materials science that coatings of a uniform thickness, which cling so tightly to the surface, can withstand higher strains before cracking by as much as 25% of the designs with fluctuating quality of surfaces.

Consequently, the Adhesion Test using tape based on ISO standards generates the strength of adhesion between coatings and the coating substrates of S220GD behind them. Data collected from people searching proves that coatings that survived these tests. Figures on durability in moist conditions increased by about 15%.

Surface Microscopy is also an important method of identifying and assessing microscopic defect profiles and microtexture. This is easily achieved by using the Scanning Electron Microscope (SEM) to manage such defects that cannot be easily observed with the naked eye.

The latest developments have also introduced the utilization of automated components for inspecting various components’ surface qualities. For instance, artificial intelligence-enabled optical systems have made it possible to scan a significant number of items in a very short time to identify the presence of nonconformities for each item. This is especially applicable in production sectors, which are characterized by high-scale processes, as it allows the maintenance of quality while deterring inefficiency in the production system.

Such extensive testing regimes and technological improvements have always managed to keep the S220gd coil and its coating within the range of competitive service lives, good design parameters, and protective solutions for harsh work sectors such as construction, automotive, and durable goods manufacturing.

What are the Packaging and Shipping Considerations for S220GD Coil?

When packaging and transporting s220gd coil, high priority is given to preserving the material and protecting its surface. The coil is usually overwrapped or wrapped in film for protection against water, dirt, and other contaminants and scratches while in transit. They use proper edge protectors and strapping to avoid being dented or damaged. And besides, they are laid directly onto the wooden pallets or cradles to keep their places and load/unload easily. When transported, it is essential to tightly contain them to restrain the coils from moving or reducing the possibility of any movement and damage through impact. All these steps are necessary so that the material is reported to the site in the best possible condition, ready to be used for its purposes.

Best Practices for Packaging Galvanized Steel Coil

| Practice | Details |

|---|---|

| Secure Packaging | Use durable straps and protective materials |

| Weather Protection | Cover with weather-resistant materials |

| Padding/Separators | Prevent coil friction and surface damage |

| Horizontal/Vertical Setup | Choose based on transport stability needs |

| Moisture Control | Use dehumidifiers or moisture-resistant wraps |

| Passivation Treatment | Apply to minimize storage stains |

| Proper Labeling | Ensure clear and durable product labels |

| Elevated Storage | Keep coils off the ground for air circulation |

| Inspection | Regularly check for damage or moisture |

| Climate-Controlled Storage | Store in dry, temperature-controlled areas |

Ensuring Safety During Shipping

To deliver s220gd coil and other related steel coils with as much safety as possible, a process that includes a comprehensive plan, field-proven packaging tools, and the ship’s rules and regulations, is needed. Given the new developments in the industry, the following are laid out guidelines together with statistics on safety during the transportation process:

- Adequate Quality of the Material of Packaging

It is essential to use strong enough packaging so that aggressive external conditions and mechanical damage do not destroy the package. From the recent industry studies, reports have indicated that the value of the global protective packaging industry was worth more than $29 billion as of 2022. Industrial goods provide the bulk of the demand with the primary materials used as thick steel straps, corner protectors, and water-resistant packaging films.

- Correct Orientation of the Loads to Provide Safety

Often, before transporting galvanized steel coils, these are held on platforms with an “eye to the sky” or level to the “eye on the side” options. The transportation spaces determine this. Most transportation with flatbed trucks requires that the coils be placed in the “eye-to-sky” position, whereas container shipping is more comfortable with the eye-to-side position. Many incidents involve shifting of load, which immediately leads to an estimated 35 percent damage associated with shipping, so proper positioning is necessary.

- Use of Advanced Means in Fixing the Cargo

It involves securing the load in reinforced straps, chains, or lashing systems. One recent enhancement introduced tension indicator straps to allow shippers to determine the amount of stress applied. It has been demonstrated that integrating interchange layers with anti-slip material has minimised the sliding effects by 70%, especially for long-distance shipments.

4。 Meeting Safety Shipping Guidelines

Complying with international shipment safety models like ISO 1161 or AAR Open Top Loading Rules is imperative. Loaded, properly prepared loads will be strengthened with various methods recognized by those standards to ensure safer travel. Percentages in the open information base indicate that such companies encountered a 40% reduction in goods damaged during shipment.

- Applying Environmental Barriers for Corrosion Damage

Due to its specific characteristics, galvanized steel is susceptible to corrosion. Therefore, turn to waterproof canvas and vapor phase inhibitors. NACE International’s research shows that steel preservation measures can increase the lifespan of equipment by half.

- Real-Time Control Feedback System

It would be imperative to use these tracking technologies in logistics, such as GPS and sensors equipped in the Internet of Things for location and state of the load. These sensors assess and provide data on impacts, vibration, and temperature changes within the load. Evidence found that real-time tracking has enabled many logistics providers to cut down the lead time of delivering to customers by up to 25 percent.

All these safety practices and technological advances present in today’s world help manufacturers and forwarders, including intact shipment, and reduce the adverse effects on shippers and patrons during this glowing economy.

References

- Steel Metallurgy – Volume 2 (ed. Lucefin, 2022)

This document discusses S220GD+ZF as a hot zinc-plated steel for structural applications, adhering to the EN 10346 standard. - Research on the Durability and Reliability of Industrial Coatings

This study includes S220GD as a research object, focusing on its metal surface protection with multilayer organic coatings. - S220GD Structure Hot-dip Galvanized Steel

This page provides detailed information about S220GD as a structural-grade hot-dip galvanized steel with a minimum yield strength of 220 MPa.

Frequently Asked Questions (FAQ)

Q: What are the key features of S220GD galvanized steel coil?

A: S220GD galvanized steel coil is known for its excellent surface appearance, formability, and weldability. It is typically used in construction and automotive applications due to its high strength and durability.

Q: How does S220GD compare to DX51D in terms of properties?

A: S220GD and DX51D are galvanized steel coils, but S220GD offers higher strength and better formability, making it suitable for more demanding structural applications. DX51D is often used in less demanding applications due to its good elongation and lower cost.

Q: What applications are suitable for S220GD+Z galvanized steel coils?

A: S220GD+Z galvanized steel coils are ideal for construction applications such as roofing, ductwork, and exhaust systems. They are also used in automotive and structural steel products due to their robust properties and weldability.

Q: What is the significance of the Z275 coating on galvanized steel coils?

A: The Z275 coating on galvanized steel coils indicates a zinc coating weight, which enhances the steel’s corrosion resistance. This makes it suitable for outdoor applications and environments where durability is crucial.

Q: Can S220GD galvanized steel be customized for specific applications?

A: Yes, S220GD galvanized steel can be customized in terms of thickness, width, and coating specifications to meet specific application requirements. This flexibility allows it to be used in various industrial sectors.

Q: What are the common standards for S220GD galvanized steel?

A: S220GD galvanized steel typically adheres to standards such as ISO, GB, JIS G3302, and AISI. These standards ensure quality control and consistent performance across different batches.

Q: What is the typical thickness range for S220GD galvanized steel coils?

A: S220GD galvanized steel coils are available in various thicknesses, typically ranging from ≤ 0.5mm to several millimeters, depending on the application and requirements.

Q: How does the hot dip galvanization process affect the properties of S220GD steel?

A: The hot dip galvanization process involves coating the steel with a zinc layer, enhancing its corrosion resistance and durability. This process also improves the surface appearance and extends the lifespan of the steel products.

Q: What is the maximum width available for S220GD galvanized steel coils?

A: S220GD galvanized steel coils are available in widths up to 1500mm, allowing them to be used in various structural and industrial applications.

Q: What factors influence the price of S220GD galvanized steel coil?

A: The price of S220GD galvanized steel coil can be influenced by coating thickness, coil dimensions, market demand, and raw material costs. Customization and specific quality requirements can also impact pricing.