Get in touch with us

Leave a message

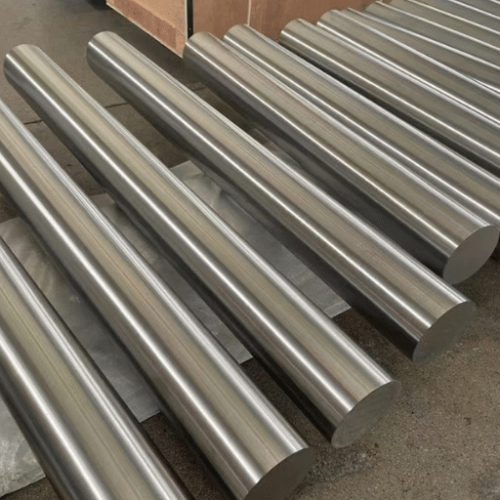

The TC21 Titanium Alloy Rod is a premium-grade titanium alloy product widely used in aerospace, automotive, and chemical industries for its exceptional mechanical properties and high corrosion resistance. Engineered to deliver superior performance, the rod is tailored for applications requiring lightweight yet durable materials that can withstand extreme environments.

For detailed pricing and specific terms regarding the TC21 Titanium Alloy Rod, please get in touch to request a quote. Pricing terms and customized solutions are available upon inquiry.

| Element | Percentage (%) |

|---|---|

| Titanium (Ti) | Balance |

| Aluminum (Al) | 5.5 - 6.75 |

| Vanadium (V) | 4.5 - 5.3 |

| Zirconium (Zr) | 2.0 - 3.0 |

| Molybdenum (Mo) | 0.8 - 1.2 |

| Iron (Fe) | ≤ 0.25 |

| Property | Value |

|---|---|

| Tensile Strength | ≥ 1100 MPa |

| Yield Strength | ≥ 1050 MPa |

| Elongation | ≥ 10% |

| Reduction of Area | ≥ 25% |

The TC21 Titanium Alloy Rod exhibits excellent resistance to acids, alkalis, and other corrosive substances. It is designed to operate effectively in both acidic and neutral saline environments.

| Environment | Corrosion Rate (mm/year) |

|---|---|

| Saltwater | < 0.1 |

| Mild Acidic Solution | < 0.2 |

| Atmospheric Environment | Negligible |

Contact us for detailed corrosion resistance data specific to your application.

The TC21 Titanium Alloy Rod is highly weldable using TIG welding and electron beam methods. Precision machining and heat treatments can further enhance its performance for tailored applications.

The TC21 titanium rod we sourced from this China manufacturer exceeded our expectations for aerospace components. Highly reliable!

Taylor L.

Aerospace Engineer

Great quality titanium bars for sale. Perfect for our medical implants with excellent biocompatibility.

Annie W.

Medical Devices

Consistent delivery and top-notch titanium industrial bar for our marine projects.

Charlie B.

Marine Equipment Supplier

Professional manufacturer of premium specialty alloys, offering stainless steel, Hastelloy, nickel-based alloys and processing services. Delivering superior metallurgical solutions for aerospace, petrochemical, marine engineering and other demanding industries.