Get in touch with us

Leave a message

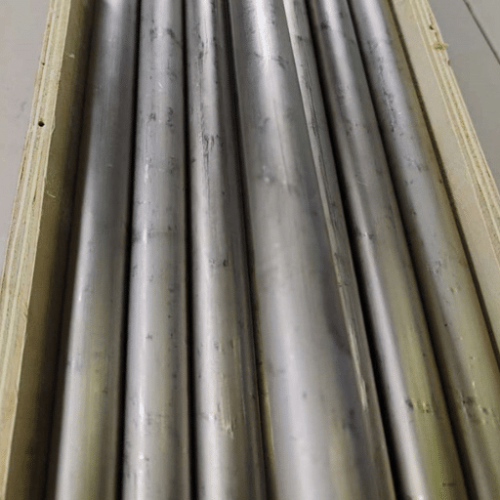

The TA2 Titanium Alloy Tube is a high-quality titanium product renowned for its exceptional corrosion resistance, lightweight structure, and impressive mechanical properties. Widely used in industries such as aerospace, medical, chemical processing, and marine engineering, this alloy combines strength and durability with unparalleled performance in extreme environments. Its biocompatibility and resistance to harsh chemicals make it ideal for critical applications, such as medical implants and heat exchangers.

To obtain a quote for TA2 Titanium Alloy Tube, please contact our sales team. Pricing terms are available upon request and depend on order volume and specifications.

| Element | Percentage (%) |

|---|---|

| Titanium (Ti) | Balance |

| Iron (Fe) | ≤ 0.30 |

| Carbon (C) | ≤ 0.08 |

| Hydrogen (H) | ≤ 0.015 |

| Oxygen (O) | ≤ 0.25 |

| Property | Value |

|---|---|

| Tensile Strength | ≥ 345 MPa |

| Yield Strength | ≥ 275 MPa |

| Elongation | ≥ 20% |

| Hardness (HB) | 160 Max |

TA2 Titanium Alloy offers excellent resistance to acids, alkalis, and chlorides. This makes it an ideal choice for environments where chemical stability is crucial, such as chemical processing plants or marine applications.

| Environment | Corrosion Rate |

|---|---|

| Atmospheric | Negligible |

| Seawater | Excellent Resistance |

| Mild Acids (e.g., H2SO4, HCl) | Good Resistance (up to certain concentrations) |

| Alkalis | Excellent Resistance |

Contact us for detailed corrosion resistance data specific to your application.

TA2 can be welded using techniques such as TIG and MIG welding, taking care to minimize oxygen exposure during the process. It is suitable for both cold and hot forming, with annealing recommended after significant deformation.

As a titanium tubing supplier for aerospace, we found TA2 tubes to be reliable and easy to fabricate. Great product!

Emma L.

Aerospace Engineer

These tubes performed flawlessly in our chemical plant. Corrosion resistance is top-notch!

Jason W.

Plant Manager

Competitive titanium tubing price and excellent quality. Highly recommend this China manufacturer.

Sam A.

Procurement Specialist

A: TA2 is unalloyed titanium with a composition emphasizing durability and light weight, while pure titanium has no additional elements and is less strong.

A: Yes, it’s biocompatible and widely used in medical applications such as surgical implants and prosthetics.

A: TA2 offers excellent resistance to seawater corrosion, making it suitable for marine applications.

A: Aerospace, medical, marine, and chemical processing industries rely heavily on TA2.

A: TA1 is significantly lighter than steel while maintaining excellent strength.

Professional manufacturer of premium specialty alloys, offering stainless steel, Hastelloy, nickel-based alloys and processing services. Delivering superior metallurgical solutions for aerospace, petrochemical, marine engineering and other demanding industries.