In today’s manufacturing and industrial fields, one core asset is materials. They seek to maintain high standards in how processes are carried out. Due to its strength, one of the core functional materials used wastefully is cold-rolled DC01 or Grade DD01 steel. However, the ability to fabricate and easy cleaning qualifications has made DC01 steel an indispensable element used in a wide range of applications in building, automotive, and furniture industries, among many others. This could explain the constrained in demand for its use. Where can we find technology that makes steel DC01 distinctly better than normal stocks in various ranges? DC01 is a premium grade steel in the automotive industry that performs selected functions of trim components, specifically in a domestic environment. This article aims to detail significant details about the grades of DC01 steel. This presents the readers with the reasons why DC01 is a necessity not only in engineering but also in design. The guide is aimed at manufacturers, designers, and enthusiasts interested in understanding DC01 steel: what it is good for and how it can be applied.

Introduction to DC01 Steel

The prevalence and popularity of DC01 steel grades all about the everyday applications of cold rolled steel, as characterized by an exceptional appearance, working properties and consistency. Applications such as automobile, construction, and homemakers use these steels because they are easy to form, weld, and include names. This steel is unfailingly flat and relatively stiff, which makes it ideal for most equipment and devices where precision and high strength are of the essence. The consequence of its sleek nature is that this steel grade permits painting and other surface finishes without compromising the application or the esthetic needs of the structure.

What is DC01 Steel?

Mild steel DC01 is a hard steel that has been cold rolled for tight tolerance and parts which require superior surface finish, thickness consistency and good formability properties that enable its versatility for bending, forming and also coatings processes.Typical Holdels of this grade are all about DC01 steel because this is an eastern central European organized country; therefore, it is pretty much self-explanatory. However, looking at the grades all about DC01 steel, as we go on, we act as a state-level registered too.

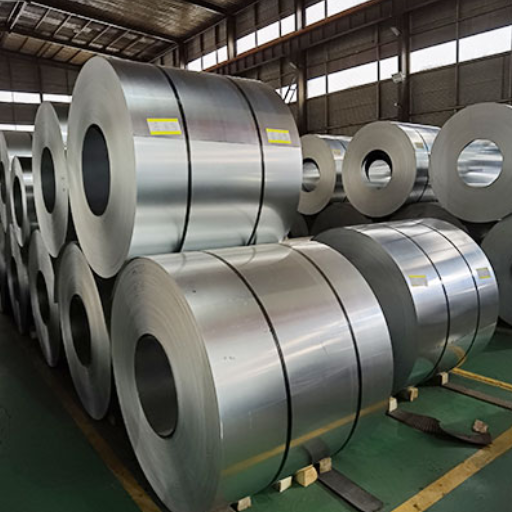

Overview of Cold Rolled Steel

There is a category of steel known as cold-rolled and hot-rolled. With cold rolled steel, the metal is subjected to an additional formative process after it has been hot rolled to make it more precise in dimensions, surface finish, and mechanical properties. While hot-rolled steel is formed at elevated temperatures, cold-rolled steel is not. Instead, cold rolling is achieved at ambient temperatures and any such deformation is done at room temperature. In this method, thinner sheets or strips are passed through pairs of rollers to compress and impose the tissue, causing stricter tolerance levels and some decent improvement in surface textures.

Important and distinguishing characteristics:

- Augmented Hardness: Cold working during the rolling process increases steel’s tensile and yield strength. This is particularly beneficial when the conditions of use include high strength requirements.

- Smoother Surface: Instead, this process results in a less rough surface, which is quite desirable for products such as automobiles, household appliances, and delicate apparatuses, where the appearance counts.

- Greater Dimensional Accuracy: Cold rolling allows manufacturers to control thickness evenly and achieve stiffer thickness tolerances than hot rolling, which is suitable for more advanced fabrications or assemblies.

- Flexible: It is readily surrogated manufactured, for example, by combining and covering, which shows its wide usability in different areas.

Examples of Where Cold-Rolled Steel Can Be Used

Cold rolled steel has numerous advantages and can be applied in such industries as:

- Automobile production includes body work, support parts for the doors and boots, and the frame section.

- Building – includes materials for roofs, beams, or walls.

- Manufacturing – includes enclosures, machine component manufacturing, and electrical cabinet fabrication.

- Appliance – which includes provisions for refrigerators and washers, amongst other appliances, for domestic or industrial use.

- Precision Engineering – where there is a need for precision and smoothness of specific details.

Market Analysis and Forecast

Based on the market analysis and conditions, the demand for cold-rolled steel is expected to increase at a CAGR of 6 – 7% within the next seven years from 2023 to 2030. This is due to their increased use in the automotive sector and manufacturing industry, which requires stronger materials and light weight. Of course, Asian countries, mainly China and India, take the leading role in consumption, taking more than half of the world, with fast economic growth, and the construction industry is active in these countries.

Again, steel can be recycled, which is why it is preferred by most manufacturers who are sensitive to environmental issues. Trend reports show that with improvements in manufacturing processes, for example, certain specialized rolling systems equipped with modernized rolling stock inspection, their perceived benefits will cause their demand curve to trend upwards within the foreseeable time frames.

Importance in Modern Manufacturing

Steel is widely used in manufacturing due to its various benefits, including strength, sustainability and adaptability. It is used in many different sectors to increase output as well as innovation. Here are five points to explain modern usage of steel and its irreplaceability in modern manufacturing;

- Developments in Motor Vehicles

Every car has some steel. Modern cars contain a high percentage of high-strength steel in their frames, usually upwards of 60 percent. These steels also help to make car body frames lighter, which in turn increases the vehicle’s fuel economy.

- Construction and Infrastructure

Over fifty percent of every steel produced presently is used to build structures such as high-rise buildings, bridges or even houses for people. As recycling and corrosion resistance are undeniable properties of steel, with the global trends of urban growth and environmental protection, the construction of steel buildings is justified.

- Energy Sector Uses

Steel is considered to be fundamental to almost all renewable energy programs. Every megawatt of power generated from windmills takes roughly 140 tons of steel, whereas oil and gas distribution systems rely on highly durable steel in the construction of pipelines for assured delivery.

- Kitchen and Other Household Products

Most kitchen appliances are composed of stainless steel because of its great looks and durability. Steel is highly preferred for such products, such as refrigerators or washing machines, because there will be no effect of excessive usage.

- Tools and Tooling Machine

It is used for industrial machines and tools in various manufacturers. Due to its high machinability, it can perform well in all the production processes as required.

Other steel applications and technological advances in steel grades, all about DC01 steel production, make these points clear that they will continue to exist and grow in modern manufacturing processes.

Chemical Composition of DC01 Steel

DC01 steel is a low-carbon grade of steel which is cold-rolled, and primarily used in form applications. Its typical chemical composition is, but not limited to, the following elements:

- No more than 0.12% of C (Carbon)

- No more than 0.60% of Mn (Manganese)

- No more than 0.045% of P (Phosphorus)

- No more than 0.045% of S (Sulfur)

Such precise composition allows DC01 steel to have a high-quality surface and sustain various mechanical processes, which always accompany these grades.

The composition of steel sheets cloud standards does not only concern DC01 steel; they can be applied to all deep-drawing steels and beyond, naturally hardened, non-alloyed, galvanized, or non-galvanised.

Elements in DC01 Steel

Steel grades are all about the balance of chemical compositions influencing the mechanical characteristics of the steel. So, DC01 is not an exception; its composition is also purposefully calculated. Look at the main components of the DC01:

- Carbon (C): Maximum 0.12%

Carbon is one of the most essential elements of steel; it serves the purpose of hardening steel. Because of the low carbon content in DC01, the steel is readily ductile and can be easily formed. Such applications are mainly intended for cold-forming operations as software, so no cracks are developed upon forming.

- Manganese (Mn): Maximum 0.60%

Manganese strengthens by acting as a deoxidizer and enhancing tensile strength. It also improves the wear resistance and ductility of the material, thus avoiding tearing or fracturing the part during forming. The Strict Contents of Manganese Achieve Maximum Life of the Parts without Sacrificing Formability.

- Phosphorus (P): Maximum 0.045%

Phosphorus increases steel strength, although too much of it makes steel more brittle. To achieve efficient forming of small-gauge steel, a low and controlled phosphorus content, as in the case of DC01, assures sufficient strength combined with ductility.

- Sulphur (S): Maximum 0.045%

Sulphur is mostly undesirable in steels; however, a minimal amount is necessary to ease machining. DC01 steel is optimized for the amount of Sulfur to prevent inconsistencies and defects on the surface, especially important for high-precision uses.

- Minor Elements (Traces):

Traces of these elements improve steel properties. Silicon (Si) and Aluminum (Al) in minute amounts are found in the carbon steels. This usually serves as a deoxidant addition or stabilizing steel. Its presence in steel slightly increases the strength, whereas aluminum reduces the material’s thickness and grain size during cold rolling.

Mechanical Properties of DC01 Steel

Chemical content influences all mechanical parameters of the DC01 steel grade. This is precisely why such grades are used in manufacturing parts that require a very high-quality surface finish and exact measurements. The usual values are the following, based on the industry specification:

- Yield Strength ≤ 280 MPa and >140 MPa

- Tensile Strength ≤ 410 MPa and >270 MPa

Minimum Elongation in % at a Thickness of below 2.00 mm is 28% Add to these features, together with the proper chemistry of the material, this tool, MPS, also allows users in sectors like automotive, appliance, and general engineering. Its ability to retain surface quality and its form, regardless of the process used, presents several benefits to the industries where beautification processes or complex manufacturing approaches are carried out.

Understanding 1.0330

This low-carbon steel, rolled and normalized, or DC01, named 1.0330 according to the standard EN 10130, is a cold-rolled low-carbon grade of steel with good drawability and renewed surface. It has the strength of stretching and toughness applied to this type of consumer product, as in the automobile industry, household appliances, etc. I think the requirements given on the steel make sense because the steel grades all about DC01 steel are the ones that have almost similar contributions to both the mechanical properties and surface finish.

Comparison with Other Low-Carbon Steels

| Category | DC01 Steel | Other Low-Carbon Steels |

|---|---|---|

| Carbon Content | ≤ 0.12% | Typically ≤ 0.2% |

| Manganese Content | ≤ 0.60% | Up to 1.6% |

| Tensile Strength | 270–410 MPa | 370–510 MPa |

| Yield Strength | 140–280 MPa | Around 210–250 MPa |

| Elongation | ≥ 28% | Typically 20-25% |

| Hardness | 105 HV | Around 120 HB |

| Surface Quality | Smooth, ideal for coatings | Rough, industrial finish |

| Formability | Excellent, supports deep drawing | Moderate, less suitable for precise forming |

| Primary Applications | Automotive, appliances, furniture | Construction, machinery, general framework |

| Corrosion Resistance | Low, requires coatings | Slightly better with added copper |

| Weldability | Excellent for precision applications | Good for structural tasks |

| Cost | Higher due to cold-rolling process | Lower, standard manufacturing methods |

Mechanical Properties of DC01 Steel

There is no other type of steel that is as strong and as elastic as the DC01. Its yield strength often falls between 140 and 280 MPa, whereas its tensile strength ranges between 270 and 410 MPa. Moreover, DC01 steel has an elongation of up to 28%, which shows it is very ductile. This combination of properties makes this steel grade very useful for exacting forming operations and in situations where the part still needs to perform correctly. So many examples where such thin sections would be found include components for cars and such household appliances, which are made of DC01 steel, основатель those appliances.

Tensile Strength and Hardness

| Category | DC01 Steel | Comparison Steels |

|---|---|---|

| Tensile Strength | 270–410 MPa | 370–510 MPa (typical steels) |

| Yield Strength | 140–280 MPa | Around 210–250 MPa |

| Elongation | ≥ 28% | 20–25% |

| Brinell Hardness | 85–120 HB | 120–150 HB (structural steels) |

| Rockwell Hardness | 50–70 HRB | 60–80 HRB |

| Vickers Hardness | 90–130 HV | 120–150 HV |

| Formability | Supports deep shaping | Less forming flexibility |

| Industrial Usage | Precision parts, plating | Structural and heavy machinery |

Formability and Ductility

| Category | DC01 Steel | Comparison Steels |

|---|---|---|

| Elongation | ≥ 28% | Often 20–25% |

| Bending Properties | Excellent, resists cracking | Moderate, higher cracking risk |

| Deep Drawing | Ideal for complex shapes | Less suitable |

| Toughness | High due to low carbon | Moderate |

| Surface Quality | Smooth, allows precise shaping | Rougher, limits forming |

| Precision Forming | Superior with tight tolerance | Limited precision |

| Industrial Applications | Auto parts, furniture, appliances | Construction, heavy machinery |

Impact Resistance

The capacity of a solid to take a definite amount of energy until it breaks is known as its impact resistance. Materials with good impact properties are needed in applications where durability and safety remain key, such as infrastructure, aerospace, and automotive components.

Latest Figures on Impact Property

- Charpy Impact Results

- Generally, steels exhibit negligible ductility in the ordered structures, with 20–30 J energy absorption at ambient conditions.

- Alloyed steels for specific thickness categories achieve 40–60 J energy levels at the same temperature of test.

- Effects of Temperature

- The impact resistance of structural steel naturally degrades at negative temperatures, reducing by 30 – 50% (depending on the alloy) at some extent.

- They are known to absorb a smaller amount of energy (10%—20%) after undergoing elaborate treatment. High-grade tuning for low-temperature applications, developed alloys retain their properties better.

- Causes of the Impact Materials Resist Steps Applied to Understand the Impact Resistance

- The phases had an intense effect on mechanical behavior. Specifically, toughness and ductility improved with an APB decrease in grain size.

- The reduction of the corner material thickness causes an increase in the impact knockout values, for example, with the induction of heat treatments such as quenching, which aims to achieve a tempered martensitic structure.

- Norms on the presence of impurities: Additional difficulties arise as impurities and nickel-to-vanadium additions influence temperature toughness.

- Application Areas

- Car Manufacturing: High-impact steels are used to make able parts in crush zones that absorb impact energy to protect bench passengers in a crash.

- Design for Performance: Materials engineered for seismic areas are used in these areas to protect against shocks.

- Aviation: Implemented materials to protect without breaking the structure from impact or even sudden pressure.

Thanks to the current burning need for materials that do not pose impact resistance problems, the effort is on the use of living forces within the element, dubbed compatible chemical compositions, offering more safety and efficiency of materials in the most unfavorable conditions.

DC01 Steel Equivalent Grades

But what are the other grades all about when it comes to DC01 steel?

- EN 10130(Named-Germany)- DC01 <br>

- ASTM A1008(United States) Joint – CS Type A <br>

- Japanese Industrial Standard JTHOME G3141 – SPCC <br>

- Standard Used By All Countries In The World – ISO 3574(Drawinggrade) – CR1 – <br>

The above equivalencies address the need for harmonization in different markets, but at the same time, they allow for slight differences in mechanical and chemical characteristics.

DIN EN 10130 and DIN EN 10152

| Category | DIN EN 10130 | DIN EN 10152 |

|---|---|---|

| Application | Cold-rolled uncoated steel sheets | Electro-galvanized steel sheets |

| Material Type | Non-alloy and alloy steel grades | Electro-coated cold-rolled steels |

| Coating | No surface coating specified | Zinc coating for corrosion resistance |

| Forming Capability | Excellent for drawing and shaping | Good for coating-required forming |

| Mechanical Properties | Controlled strength, high elongation | Similar, with a galvanization focus |

| Surface Quality | Ideal for painting or surface use | Enhanced for coated environments |

| Main Industries | Automotive, appliances, furniture | Automotive, construction, appliances |

Comparative Analysis with Equivalent Grades

| Category | DC01 Steel | Equivalent Grades |

|---|---|---|

| Chemical Composition | ≤ 0.12% C, ≤ 0.6% Mn | Similar low-carbon content |

| Tensile Strength | 270–410 MPa | Comparable across equivalents |

| Yield Strength | 140–280 MPa | Slightly varying by standard |

| Elongation | ≥ 28% | Typically 20–30% |

| Hardness | 85–120 HB | Matches within equivalent range |

| Applications | Automotive, appliances, furniture | Similar industrial uses |

| Standard Compliance | EN 10130 | SAE 1008, JIS SPCC, St12 |

| Surface Quality | Smooth, suited for coatings | Similar finish conditions |

| Weldability | Excellent due to low carbon | Consistently high |

| Formability | Deep drawing and shaping | Matching formability levels |

Choosing the Right Equivalent Grade for Your Needs

Finding the right substitute grade to use additionally varies with the applications specified since functionality, longevity, and cost-effectiveness are subjects that are best addressed in the right choice of raw materials. The following will give an overview of a different set of equivalent grades widely used today, as well as their main properties and utilization:

- Grade A992 (High Strength Low Alloy Steel)

- Main properties: excellent toughness, weldability & machined fairly easily.

- It is used in construction, bridges, and these grades are all about steel.

- The provision of grade 304 (stainless steel).

- Basic characteristics: contains corrosion resistant, dimensions, used.

- Applications: Kitchen appliances (especially attachments), medical tools, chemical manufacturing, etc.

- Grade G90 – Galvanized

- Key attributes: temperature resistant due to the respective thick zinc film G90.

- Use: Roofing, walls, and any outside architecture where the weather is not playing a positive role.

- EN 10149-2 Lean 2 grmn S355MC

- The most appropriate and useful characteristic of S355MC is its Ultra mobility – high strength form, lowering ABS load conversion – already thermal stability transition temperature becomes a critical challenge.

- It is used in industries such as the automobile and heavy equipment.

- Using mainly 6061 aluminum alloy extruded shapes.

- It has high strength-to-weight ratios, is lightweight, and is corrosion resistant.

- Applications in this range will mostly involve presence in some transport modes, aerospace infrastructure, or even where ‘the sea to the carrier’ defence context exists.

Another type of stress relief shrinks, making it unsuitable for premium grades of DC01 steel patterns.

Bulk density, purposely, is based on the homogeneity and presentability of the five Grade figures.

Trends and Advancements in the Steel Industry

Technology and sustainability are forcing significant change in the steel sector and the way it is produced. A few are listed below:

- Sustainability: Steel practitioners worldwide pay attention to novel ways to control emissions through innovative technologies such as green steel production, particularly renewable energies or recycling.

- Lightweight materials: More developed materials such as advanced high-strength steel or alloys for use in car engineering, building, and aircraft manufacture.

- Man as ‘steel’ free digital systems: Introducing innovative AI systems in the steel sector to increase the efficiency in packaging, quality control, and operations.

- Total Energy Dynamics: Steel powders to iron sheet, almost all parts of steel may be printed and also some innovative and green geometrical features may be achieved with such technologies.

- Close-the-Loop Concepts: Further enhancement of steel recycling and reuse to discourage production waste and steel wastage.

Due to such progress, increased productivity, and strategic global competition, the growth is aimed at environmental sustainability.

Recent Innovations in Cold Rolled Steel

Cold-fabricated steel is still one of the main materials used in the automotive and construction industries, and a few outstanding innovations force the material’s limits even further. An outline of the newest developments and relevant statistics for this critical material improvement follows:

- Aluminum and High-Strength Steel

Third-generation AHSS has been instrumental in the development of the automobile industry. Such steels have an optimum balance between strength and ductility, which allows the making of lighter vehicles without sacrificing safety. In recent studies, these materials have increased vehicle weight savings by about 15-25%, thus offering better fuel consumption and reducing C02 emissions.

- Surface Finish and Coatings Modifications

Cold-rolled steel is now subjected to revolutionary surface finishing processes. Moreover, the addition of coatings containing zinc-aluminium-magnesium (ZAM) protective alloys has enhanced steel anti-corrosion characteristics, increasing the service life of the component. To illustrate, the ZAM-coated cold-rolled steel proved to have almost ten times more corrosion resistance than common galvanised steel.

- Micro Model and Hi-tech Equipment

Recent advances in the design of rolling and annealing methods would also permit the creation of cold-rolled steel with much improved dimensional precision and a narrower thickness range. Evidence suggests that the modern set of equipments allows maintaining dimensional inconsistency below ±0.005 mm, which implies perfect suitability of such materials for such applications as electronics casings and domestic products, which require close tolerance levels.

- Energy Preservation and Recycling: Towards Sustainable Growth

In this regard, the steel sector, with the cold rolled steel into consideration, has made strides in energy efficiency. The production of cold-rolled steel is keen on saving the environment, like the use of electric arc furnaces recently adopted in the industry, which allows the smelting of scrap steel, reducing the energy used by nearly 50% compared to the blast furnace. It is estimated that more than 85% of steel is recycled in the world, making it the most recycled material in today’s processing industry.

- Digital Inclusion and Bespoke Products

Manufacturers are utilizing digital technology such as AI and IoT within the production process to offer custom cold-rolled steel production. These technologies enable the production process to be monitored and controlled in real time, leading to better products with less waste. It has been reported that AI application in steel production increased the yield by reducing the number of nonconforming products by even 30 %, which means cost savings and performance enhancement.

Advancements in cold-rolled steel are meant to satisfy the growing market needs and improve performance and sustainability.

The Role of Zinc Coating in DC01 Steel

| Category | Details |

|---|---|

| Corrosion Resistance | Protects steel from rust and wear |

| Coating Types | Electro-galvanized, hot-dip |

| Thickness Levels | Ranges from 25 to 100 µm |

| Durability | Prolongs steel lifespan |

| Surface Finish | Enhances smoothness for coatings |

| Key Applications | Automotive, appliances, construction |

| Environmental Benefits | Reduces need for replacements |

| Adhesion Quality | Ensures strong paint bonding |

| Moisture Protection | Shields steel from humid conditions |

| Cost Efficiency | Balances quality and longevity |

Future Outlook for DC01 Steel in Manufacturing

I see many prospects in the manufacturing industry that will involve DC01 steel shortly. Due to its excellent buildability and flexibility, this steel has succeeded in coping with different uses, such as the automotive industry and construction purposes. The scope for the efficiency of DC01 rolled steel can be increased with the improvement of coating techniques and the use of sustainable technologies, thus increasing its durability and making the steel more eco-friendly to supply the high demand of efficient and green manufacturing.

References

- Effect of Processing Route on Microstructure and Microhardness of Low-Carbon Steel Subjected to Drece Process

Read the paper here - Influence of Variability of Mechanical Data on Forming Limits Curves

Read the paper here - Laser Assisted Joining of Dissimilar Materials

Read the paper here

Frequently Asked Questions (FAQ)

What is DC01 Steel and its Chemical Composition?

DC01 steel is a non-alloy cold-rolled steel that falls under the category of low carbon steel, characterized by a carbon content of 0.06% to 0.12%. It is primarily used in the production of flat products. It is known for its excellent cold formability and strength, making it suitable for various applications across industries, particularly in the automotive sector.

How Does the Yield Strength of DC01 Steel Compare?

DC01 steel’s yield strength typically ranges from 270 to 410 MPa, making it a reliable choice for applications requiring good mechanical properties. Its lower yield strength compared to other steel grades allows for easier cold forming processes, which is beneficial in manufacturing complex shapes without cracking.

What are the Surface Quality Standards for Cold-Rolled Flat Steel?

According to DIN EN 10130 standards, the surface quality of cold-rolled flat steel, including DC01, is critical for ensuring the durability and aesthetic appeal of the final product. High surface quality is achieved through careful processing and quality control measures, which help prevent rust and surface imperfections.

What Advantages Does DC01 Steel Offer for the Automotive Industry?

DC01 steel provides significant advantages for the automotive industry due to its combination of low carbon content, high tensile strength, and excellent elongation properties. These attributes ensure that it can withstand the stresses of cold forming processes while maintaining the strength and toughness required for automotive components.

How Does the Corrosion Resistance of DC01 Steel Compare to Galvanized Steel?

While DC01 steel has some corrosion resistance due to its low carbon content, it is generally less resistant than galvanized steel coated with electrolytic zinc. The galvanization process significantly enhances the service life of steel products by providing an additional layer of protection against rust and other environmental factors.

What is the Minimum Elongation Required for DC01 Steel?

The minimum elongation at fracture for DC01 steel is specified to ensure the material can be effectively formed into complex shapes without failure. Typically, the minimum elongation is around 28%, allowing sufficient ductility during the cold forming.

What Technical Delivery Conditions Apply to DC01 Steel?

DC01 steel is governed by various technical delivery conditions specified in the EN 10130 standard. These conditions include the requirements for chemical composition, mechanical properties, and surface quality, ensuring that the steel products meet industry standards and customer expectations.

How is the Surface Finish of Cold-Rolled Steel Achieved?

The surface finish of cold-rolled steel, including DC01, is achieved through a combination of the cold rolling process and subsequent treatments. These treatments may include annealing and pickling, which enhance the surface quality and prepare the steel for further applications, such as galvanization or painting.

What is the Role of Electrolytic Zinc in Steel Products?

Electrolytic zinc plays a crucial role in protecting steel products from corrosion. When applied as a coating to DC01 steel, it significantly enhances the material’s resistance to rust and other forms of corrosion, thereby prolonging the service life of the steel in various applications.