Get in touch with us

Leave a message

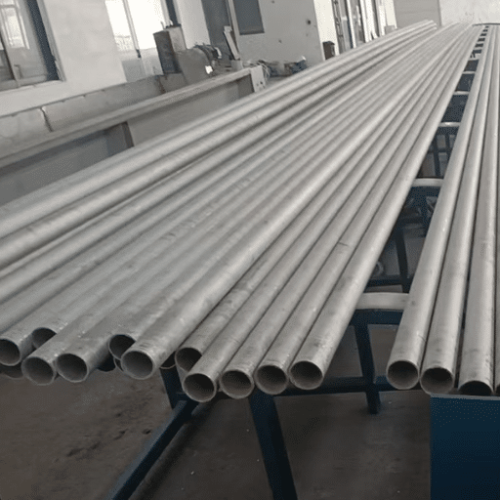

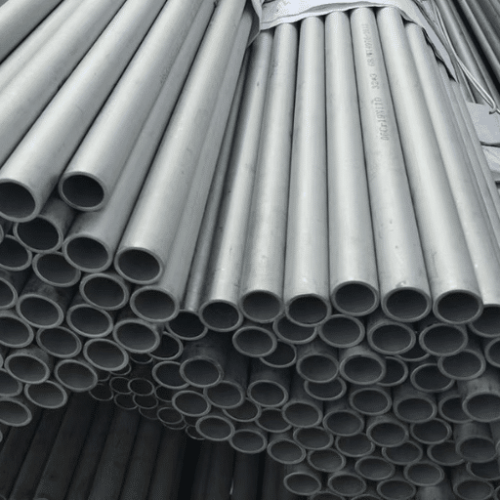

The TA4 Titanium Alloy Tube is renowned for its superior strength-to-weight ratio, excellent corrosion resistance, and exceptional durability under extreme conditions. Designed specifically for applications requiring high performance and reliability, this alloy is widely utilized in industries such as aerospace, marine, medical, and chemical processing. Its unique composition allows it to withstand harsh environments while maintaining structural integrity.

For precise pricing and quotes on TA4 Titanium Alloy Tube, please contact our team directly. Pricing terms are competitive and can vary based on order volume, specifications, and location.

| Element | Composition (%) |

|---|---|

| Titanium | Bal |

| Aluminum | 5.5 – 6.5 |

| Vanadium | 3.5 – 4.5 |

| Others | ≤0.4 |

| Element | Composition (%) |

|---|---|

| Titanium | Bal |

| Aluminum | 5.5 – 6.5 |

| Vanadium | 3.5 – 4.5 |

| Others | ≤0.4 |

The TA4 Titanium Alloy Tube exhibits excellent resistance to acids and alkalis, particularly in environments containing chlorides and sulfates. It is non-reactive to most environments, ensuring longevity.

| Environment | Resistance Performance |

|---|---|

| Atmospheric Corrosion | Excellent |

| Seawater Resistance | Outstanding |

| Acidic Solutions | High Resistance |

Contact us for detailed corrosion resistance data specific to your application.

Recommended welding methods for TA4 Titanium Alloy Tube include TIG (Tungsten Inert Gas) welding and electron beam welding. The material is easily machinable with the appropriate cutting tools and coolant to prevent overheating during processing.

We sourced TA4 Titanium Alloy Tube from this China factory for our hydraulic systems. Exceptional quality and precise dimensions!

John S.

Aerospace Engineer

Perfect for medical implants. The biocompatibility and strength exceeded our expectations.

Emily W.

Medical Device Manufacturer

These tubes held up flawlessly in seawater applications. Highly recommend this titanium tubing supplier.

Mark T.

Marine Contractor

A: TA4 alloy contains aluminum and vanadium for increased strength, whereas pure titanium does not have alloying elements and is softer.

A: Yes, its biocompatibility and strength make it ideal for medical use.

A: It is commonly used in aerospace, marine, medical, chemical processing, and industrial sectors.

A: It offers a unique balance of strength, lightweight properties, and corrosion resistance, particularly in chloride-rich environments.

A: Yes, dimensions and surface treatments can be tailored to meet specific requirements.

Professional manufacturer of premium specialty alloys, offering stainless steel, Hastelloy, nickel-based alloys and processing services. Delivering superior metallurgical solutions for aerospace, petrochemical, marine engineering and other demanding industries.