Get in touch with us

Leave a message

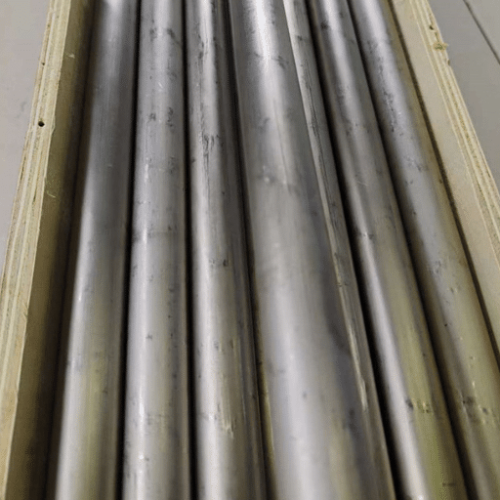

TA7 Titanium Alloy Pipe is a high-performance titanium alloy renowned for its exceptional strength, corrosion resistance, and lightweight properties. Suitable for demanding applications across aerospace, medical, and industrial sectors, this alloy delivers reliability under extreme conditions. The pipe is ideal for environments requiring durability, biocompatibility, and resistance to corrosive substances.

For precise pricing and quotes on TA4 Titanium Alloy Tube, please contact our team directly. Pricing terms are competitive and can vary based on order volume, specifications, and location.

| Element | Percentage (%) |

|---|---|

| Titanium (Ti) | Balance |

| Aluminum (Al) | 5.5 – 6.8 |

| Vanadium (V) | 3.5 – 4.5 |

| Iron (Fe) | Max 0.30 |

| Oxygen (O) | Max 0.20 |

| Property | Value |

|---|---|

| Tensile Strength | ≥ 895 MPa |

| Yield Strength | ≥ 825 MPa |

| Elongation | ≥ 10% |

| Hardness (HB) | 340 – 400 |

TA7 Titanium Alloy Pipe boasts outstanding resistance to chloride-induced stress corrosion, oxidation, and erosion in both acidic and alkaline environments. It complies with strict environmental and industry standards.

| Environment | Corrosion Rate (mm/year) |

|---|---|

| Seawater | Negligible |

| Hydrochloric Acid | 0.02 – 0.05 |

| Sodium Hydroxide | 0.01 |

Contact us for detailed corrosion resistance data specific to your application.

TA7 Titanium Alloy Pipe allows for TIG and MIG welding methods, with proper shielding gases to avoid contamination. Cold working and hot forming processes are possible, but specific equipment and expertise are recommended to achieve precision.

We used TA7 Titanium Alloy Pipe for jet engine components. Superb quality and durability!

Sarah L.

Aerospace Engineer

This pipe’s biocompatibility is perfect for medical implants. Highly reliable supplier!

Raj P.

Biomedical Engineer

Excellent corrosion resistance in seawater. Best titanium tubing supplier we’ve worked with.

Tom K.

Marine Contractor

A: TA7 is a titanium alloy with aluminum and vanadium for enhanced strength and corrosion resistance, unlike pure titanium which lacks these alloying elements.

A: Aerospace, medical, automotive, industrial, and energy sectors benefit most from its properties.

A: TA7’s high strength-to-weight ratio and corrosion resistance make it a preferred choice for aerospace components.

A: Yes, its biocompatibility and resistance to bodily fluids make it ideal for surgical implants and devices.

A: Lead times depend on order size and customization but typically range from 4 to 8 weeks.

Professional manufacturer of premium specialty alloys, offering stainless steel, Hastelloy, nickel-based alloys and processing services. Delivering superior metallurgical solutions for aerospace, petrochemical, marine engineering and other demanding industries.