Get in touch with us

Leave a message

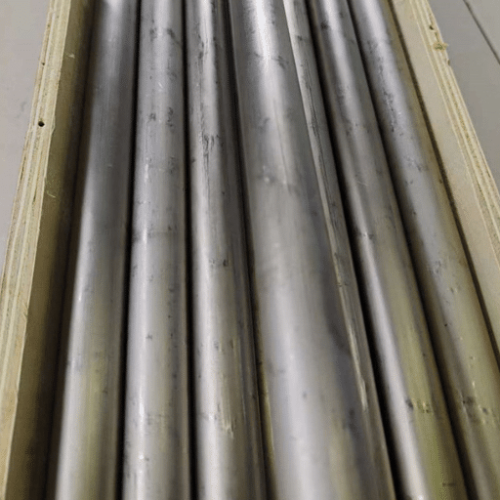

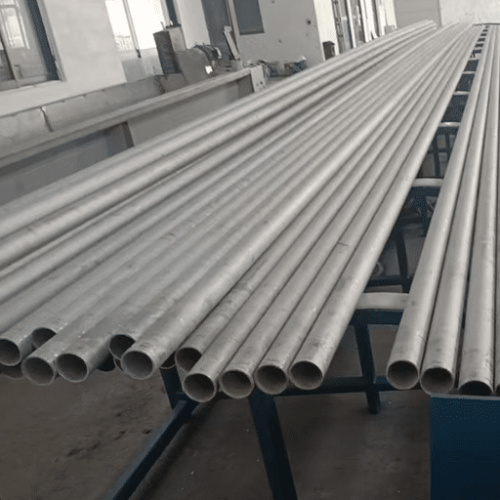

The TA15 Titanium Alloy Tube is a high-performance alloy known for its excellent strength-to-weight ratio and exceptional corrosion resistance. Widely used in aerospace, medical implants, and other demanding industries, this alloy combines robust mechanical properties with versatility in fabrication, making it indispensable for both structural and precision applications.

For pricing inquiries on TA15 Titanium Alloy Tube, contact our enterprise. Pricing terms are tailored to order specifications, and quotes include information on quantity, dimensions, and delivery terms.

Technical Specifications include:

TA15 Titanium Alloy Tubes are suitable for:

| Element | Percentage (%) |

|---|---|

| Titanium (Ti) | Balance |

| Aluminum (Al) | 6.0-7.0 |

| Zirconium (Zr) | 1.5-2.5 |

| Molybdenum (Mo) | 0.5-1.5 |

| Vanadium (V) | 0.5-1.5 |

| lron (Fe) | ≤0.25 |

| Oxygen (0) | ≤0.15 |

| Property | Value |

|---|---|

| Tensile Strength | ≥900 MPa |

| Yield Strength | ≥830 MPa |

| Elongation | ≥10% |

| Hardness (HB) | 280-320 |

| Environment | Corrosion Rate (mm/year) |

|---|---|

| Atmospheric Conditions | < 0.01 |

| Seawater | < 0.02 |

| Mild Acid Solutions | < 0.05 |

Contact us for detailed corrosion resistance data specific to your application.

As titanium tubing suppliers, this company delivered high-quality TA15 tubes for our aerospace project. Excellent service!

Tom A.

Aerospace Engineer

The TA15 Titanium Alloy Tube outperformed expectations in our marine application. Highly recommend!

Sophia K.

Marine Equipment Manufacturer

Reliable titanium alloys for medical implants. Fast delivery and great support.

Jack P.

Medical Device Company

A: TA15 offers superior strength-to-weight ratio and high-temperature resistance compared to standard titanium grades.

A: Yes, its biocompatibility and resistance to body fluids make it an excellent choice for medical applications.

A: TA15 exhibits exceptional performance in seawater, maintaining stability and strength.

A: Yes, with proper techniques like TIG and MIG welding, excellent results can be achieved.

A: They are extensively used in aerospace, medical, automotive, and industrial sectors.

Professional manufacturer of premium specialty alloys, offering stainless steel, Hastelloy, nickel-based alloys and processing services. Delivering superior metallurgical solutions for aerospace, petrochemical, marine engineering and other demanding industries.