Get in touch with us

Leave a message

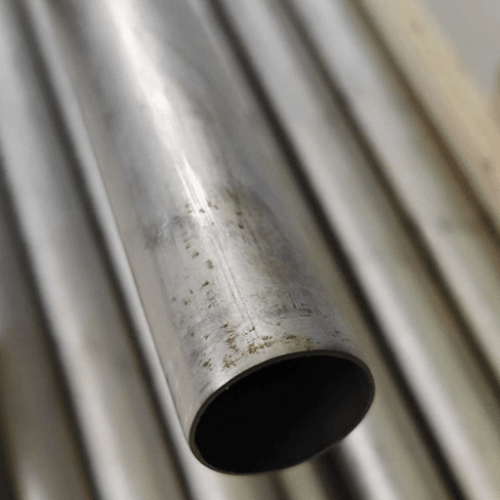

The TA15 Titanium Alloy Tube is a high-performance alloy known for its excellent strength-to-weight ratio and exceptional corrosion resistance. Widely used in aerospace, medical implants, and other demanding industries, this alloy combines robust mechanical properties with versatility in fabrication, making it indispensable for both structural and precision applications.

For pricing details on TC4 Titanium Alloy Pipe, please contact us to obtain a quote. Pricing terms and discounts may vary depending on the order size and specifications.

The TC4 Titanium Alloy Pipe is commonly used in the following industries and scenarios:

| Element | Percentage (%) |

|---|---|

| Titanium (Ti) | Balance |

| Aluminum (Al) | 5.5 - 6.75 |

| Vanadium (V) | 3.5 - 4.5 |

| Iron (Fe) | ≤ 0.30 |

| Oxygen (O) | ≤ 0.20 |

| Carbon (C) | ≤ 0.08 |

| Nitrogen (N) | ≤ 0.05 |

| Property | Value |

|---|---|

| Tensile Strength | ≥ 895 MPa |

| Yield Strength | ≥ 825 MPa |

| Elongation | ≥ 10% |

| Modulus of Elasticity | 110 GPa |

| Density | 4.43 g/cm³ |

TC4 Titanium Alloy Pipe exhibits excellent resistance to:

| Environment | Resistance Level |

|---|---|

| Marine Water | Excellent |

| Sulfuric Acid (10%) | Good |

| Hydrochloric Acid | Moderate |

| Atmospheric | Excellent |

Contact us for detailed corrosion resistance data specific to your application.

The recommended welding methods for TC4 Titanium Alloy Pipe include TIG (Tungsten Inert Gas) and plasma arc welding. Cold forming is ideal for shaping, and annealing may be prescribed to enhance ductility and reduce residual stress.

These TC4 pipes are perfect for our airframe projects. The titanium alloy composition ensures durability and lightweight performance.

Marco P.

Aerospace Engineer

We rely on these pipes for medical implants. Excellent biocompatibility and consistent quality from this titanium tubing supplier.

Kelly W.

Medical Device Manufacturer

Reliable titanium alloys for medical implants. Fast delivery and great support.

Anthony F.

Medical Device Company

A: TC4 offers higher strength and structural integrity, making it more suitable for demanding applications.

A: Yes, it is highly resistant to marine corrosion, making it ideal for offshore and marine applications.

A: The melting point is approximately 1,660°C.

A: Yes, its biocompatibility and resistance to body fluids make it widely used in medical applications.

A: TC4 (Ti-6Al-4V) is one of the strongest and most versatile titanium alloys, offering an excellent balance of durability and weight.

Professional manufacturer of premium specialty alloys, offering stainless steel, Hastelloy, nickel-based alloys and processing services. Delivering superior metallurgical solutions for aerospace, petrochemical, marine engineering and other demanding industries.