Get in touch with us

Leave a message

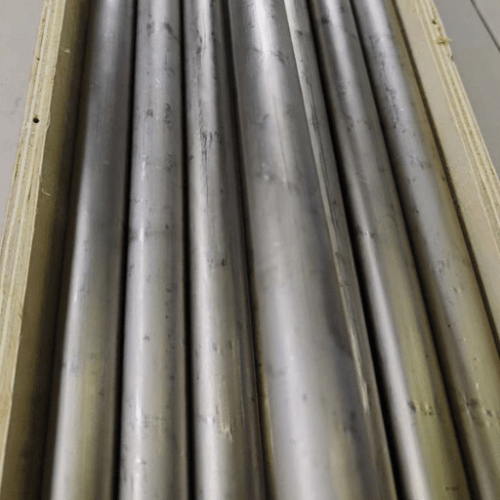

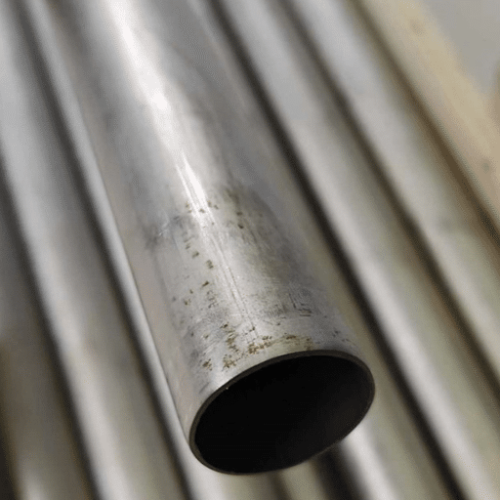

The TC6 Titanium Alloy Tube is a premium-grade material widely used in critical industries such as aerospace, medical, and automotive. Known for its exceptional strength-to-weight ratio, corrosion resistance, and high-temperature performance, TC6 is a versatile alloy suitable for demanding applications that require superior mechanical properties.

For pricing information and detailed quotes on TC6 Titanium Alloy Tubes, please contact us directly. Pricing terms depend on volume, specifications, and delivery requirements.

| Element | Percentage (%) |

|---|---|

| Titanium (Ti) | Balance |

| Aluminum (Al) | 5.5-6.5 |

| Molybdenum (Mo) | 2.0-3.0 |

| Chromium (Cr) | 1.0-2.0 |

| lron (Fe) | 0.3-0.7 |

| Silicon (Si) | 0.2-0.4 |

| Property | Value |

|---|---|

| Tensile Strength | >900 MPa |

| Yield Strength | >800 MPa |

| Elongation | ≥10% |

| Hardness | 300-340 HB |

| Density | 4.51 g/cms |

The TC6 Titanium Alloy Tube offers excellent resistance to a wide range of acids and alkalis due to its protective oxide layer. It performs exceptionally well in both neutral and mildly acidic environments but should be used with caution in highly chlorinated or fluoride-rich conditions. The alloy meets environmental restriction standards for industrial applications.

| Environment | Resistance Level |

|---|---|

| Atmospheric | Excellent |

| Seawater | High |

| Mild Acidic Solutions | High |

| Strong Acids | Moderate |

Contact us for detailed corrosion resistance data specific to your application.

As titanium tubing suppliers, this China factory delivered high-quality TC6 tubes for our aerospace project. Excellent service!

Suzy R.

Aerospace Engineer

The TC6 Titanium Alloy Tube exceeded expectations in our medical implant production. Reliable and biocompatible.

John Y.

Medical Manufacturer

Great value for titanium tubing price. Perfect for our marine application with superb corrosion resistance.

Johnson P.

Marine Contractor

A: TC6 titanium alloy contains aluminum and vanadium elements, enhancing its strength and thermal performance compared to pure titanium.

A: Yes, the TC6 Titanium Alloy Tube can be customized in terms of dimensions, surface finish, and other specifications.

A: Yes, it is biocompatible and meets the stringent requirements of the medical industry for implants and orthopedic devices.

A: TC6 titanium alloy offers a higher strength-to-weight ratio compared to stainless steel, making it a superior choice for weight-sensitive applications.

A: Lead times depend on order volume and specific requirements but typically range between 4-8 weeks.

Professional manufacturer of premium specialty alloys, offering stainless steel, Hastelloy, nickel-based alloys and processing services. Delivering superior metallurgical solutions for aerospace, petrochemical, marine engineering and other demanding industries.