Get in touch with us

Leave a message

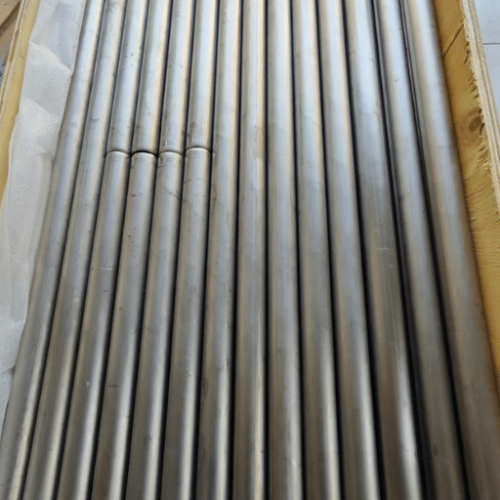

The TC11 Titanium Alloy Tube is a high-performance material designed for demanding applications across various industries. This advanced titanium alloy offers exceptional strength, corrosion resistance, and high-temperature stability, making it an ideal choice for aerospace, marine, and chemical applications. Featuring precise manufacturing standards, the TC11 Grade tubing ensures reliability and durability even under extreme conditions.

For pricing inquiries regarding the TC11 Titanium Alloy Tube, please contact us directly to receive a personalized quote based on your specific requirements. Pricing terms include bulk orders and lead times, ensuring competitive market rates for high-quality titanium products.

The TC11 Titanium Alloy Tube is highly versatile and commonly used in the following industries and applications:

| Element | Composition (%) |

|---|---|

| Titanium (Ti) | Balance |

| Aluminum (Al) | 6.0 - 7.0 |

| Zirconium (Zr) | 4.5 - 5.5 |

| Molybdenum (Mo) | 1.5 - 2.5 |

| Property | Value |

|---|---|

| Tensile Strength | ≥ 950 MPa |

| Yield Strength | ≥ 860 MPa |

| Elongation | ≥ 10% |

| Reduction of Area | ≥ 25% |

The TC11 Titanium Alloy exhibits excellent resistance to a wide range of acids and alkalis, providing superior durability in aggressive chemical environments. This makes it particularly effective in applications requiring prolonged exposure to corrosive agents.

| Environment | Corrosion Rate (mm/year) |

|---|---|

| Seawater | 0.008 |

| Chloride Solutions | 0.01 - 0.025 |

| Atmospheric Exposure | Negligible |

Contact us for detailed corrosion resistance data specific to your application.

For welding TC11 Titanium Alloy Tubes, methods such as TIG (Tungsten Inert Gas) welding are highly recommended due to their precision and control. Preheating is not necessary, and post-weld heat treatment can optimize mechanical properties. The material is also suitable for cold forming and bending, provided proper tooling is employed to prevent deformation.

The TC11 Titanium Alloy Tube from this titanium alloy manufacturer is top-notch. Perfect for our engine components, with consistent quality and fast delivery.

David P.

Aerospace Engineer

We use these tubes for medical implants. The biocompatibility and precision are unmatched. Highly recommend this titanium tubing supplier.

Peter L.

Medical Device Manufacturer

Great corrosion resistance in our reactors. The titanium tubing price is competitive, and the supplier’s support is excellent.

Jessica F.

Chemical Plant Manager

A: Its unique composition gives it higher strength, superior corrosion resistance, and better high-temperature performance compared to standard titanium grades.

A: Yes, its biocompatibility and corrosion resistance make it ideal for medical applications.

A: TC11 offers enhanced mechanical properties and thermal stability, making it more suitable for demanding industrial applications.

A: Tubes are highly customizable, with thickness, diameter, and length tailored to customer needs.

A: Yes, the product meets industry standards such as GB/T 3624 and ASTM B861.

Professional manufacturer of premium specialty alloys, offering stainless steel, Hastelloy, nickel-based alloys and processing services. Delivering superior metallurgical solutions for aerospace, petrochemical, marine engineering and other demanding industries.