Get in touch with us

Leave a message

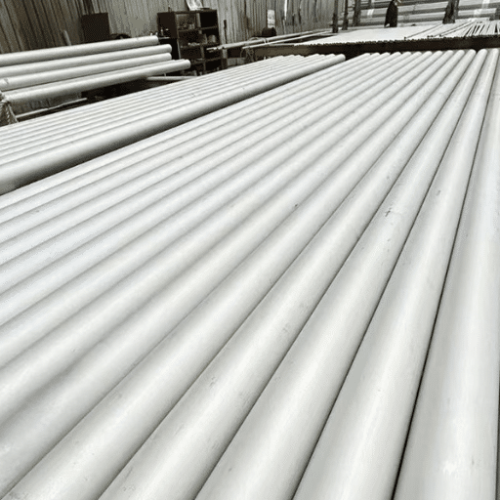

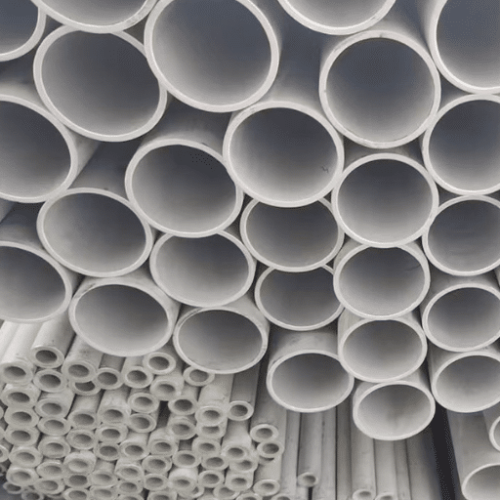

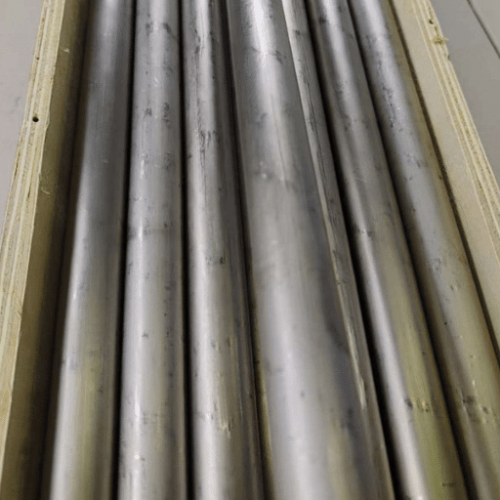

The TC21 Titanium Alloy Pipe stands out as a high-performance material widely utilized across various industries due to its exceptional strength, lightweight structure, and excellent resistance to corrosion. It is particularly favored in aerospace, medical, and marine applications, making it an indispensable choice for demanding environments.

For detailed pricing on TC21 Titanium Alloy Pipe, contact us today to request a customized quote. Pricing terms include size, quantity, and additional customization needs.

| Element | Percentage (%) |

|---|---|

| Titanium (Ti) | Balance |

| Aluminum (Al) | 5.5-6.5 |

| Tin (Sn) | 1.5-2.5 |

| Zirconium (Zr) | 1.5-2.5 |

| Molybdenum (Mo) | 2.5-3.5 |

| Chromium (Cr) | 0.8-1.2 |

| Niobium (Nb) | 1.5-2.5 |

| Property | Value |

|---|---|

| Tensile Strength | ≥1100 MPa |

| Yield Strength | >950 MPa |

| Elongation | ≥10% |

| Hardness (HB) | 320-360 |

| Density | 4.65 g/cm3 |

The TC21 Titanium Alloy Pipe offers exceptional resistance to acids and alkalis, making it ideal for highly corrosive environments. It also meets environmental standards for eco-friendly operations.

| Environment | Corrosion Rate (mm/year) |

|---|---|

| Atmospheric (Urban) | <0.01 |

| Seawater | <0.005 |

| Mild Acid (pH 4-6) | <0.02 |

| Strong Acid (pH <2) | 0.05-0.1 |

Contact us for detailed corrosion resistance data specific to your application.

Recommended welding methods include Tungsten Inert Gas (TIG) and Metal Inert Gas (MIG) welding. Fabrication requires specialized tools and slow processing speeds to ensure dimensional accuracy and prevent material damage.

TC21 Titanium Alloy Pipe outperformed our expectations in high-stress conditions. Perfect for aerospace components.

William K.

Aerospace Engineer

The biocompatibility and strength make it ideal for medical implants. Reliable titanium alloy composition.

Daniel W.

Medical Device Manufacturer

These pipes withstand harsh chemicals without corrosion. Great value for titanium tubing price.

Alice P.

Chemical Plant Manager

A: TC21 offers higher strength and thermal stability compared to standard titanium alloys like Ti-6Al-4V, making it ideal for critical applications.

A: Yes, TC21 Titanium Alloy is biocompatible and widely used in surgical implants and orthopedic devices.

A: Aerospace, medical, marine, and automotive industries are the primary users of TC21 Titanium Alloy Pipe.

A: TC21 ranks among the strongest titanium alloys, ideal for high-performance applications.

A: Pricing depends on factors like size, thickness, surface treatment, and order volume. We recommend contacting us for a detailed quote tailored to your requirements.

Professional manufacturer of premium specialty alloys, offering stainless steel, Hastelloy, nickel-based alloys and processing services. Delivering superior metallurgical solutions for aerospace, petrochemical, marine engineering and other demanding industries.