Get in touch with us

Leave a message

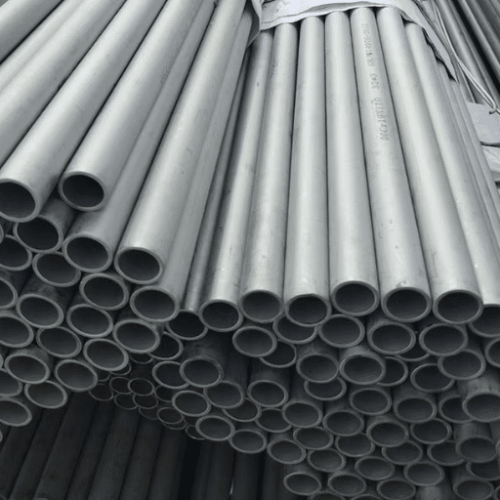

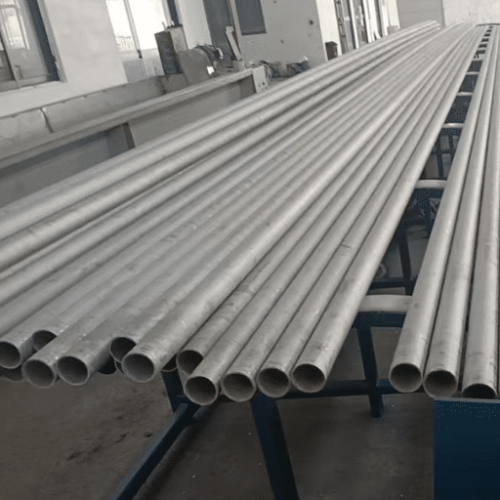

The TB6 Titanium Alloy Tube is a high-performance tubing solution renowned for its exceptional strength, lightweight characteristics, and corrosion resistance. Designed primarily for aerospace, marine, and medical applications, this titanium tubing is the ideal choice for industries requiring robust and durable materials. Perfect for environments with extreme conditions, it offers a blend of superior mechanical properties and reliability.

For pricing details regarding the TB6 Titanium Alloy Tube, please contact us directly for a custom quote. Pricing terms are flexible to meet your needs, and we ensure competitive rates for all order sizes.

| Element | Percentage (%) |

|---|---|

| Titanium (Ti) | 88-92 |

| Aluminum (Al) | 5.5-6.5 |

| Vanadium (V) | 3.5-4.5 |

| Property | Value |

|---|---|

| Tensile Strength | 895 MPa |

| Yield Strength | 825 MPa |

| Elongation | 10% |

| Density | 4.43 g/cm³ |

TB6 Titanium Alloy exhibits remarkable resistance to acids, alkalis, and marine environments, ensuring long-term durability even under demanding conditions. Its immunity to rust makes it suitable for exposure to water and chemical substances.

| Environment | Corrosion Rate (mm/year) |

|---|---|

| Saltwater (Seawater) | <0.01 |

| Mild Acid (pH 4-6) | <0.05 |

| Alkaline Solutions (pH 8+) | <0.03 |

Contact us for detailed corrosion resistance data specific to your application.

TB6 Titanium Alloy Tube is a game-changer for our hydraulic systems. Lightweight yet incredibly strong, it’s worth the titanium tubing price.

Victor P.

Aerospace Engineer

We use TB6 for medical implants. Its biocompatibility and durability are unmatched compared to other titanium alloys.

Anthony J.

Medical Manufacturer

As titanium alloy manufacturers, their quality control and customization options make sourcing TB6 seamless.

John M.

Industrial Buyer

A: TB6 offers a unique combination of high tensile strength, corrosion resistance, and lightweight properties, making it optimal for extreme environments.

A: Yes, the biocompatibility of TB6 makes it a preferred choice for medical devices and implants.

A: Aerospace, marine, medical, and power generation industries are the primary beneficiaries.

A: TB6 has enhanced strength and corrosion resistance, whereas pure titanium offers slightly lower strength but higher flexibility.

A: Yes, we offer tailored solutions to meet unique project requirements.

Professional manufacturer of premium specialty alloys, offering stainless steel, Hastelloy, nickel-based alloys and processing services. Delivering superior metallurgical solutions for aerospace, petrochemical, marine engineering and other demanding industries.