Get in touch with us

Leave a message

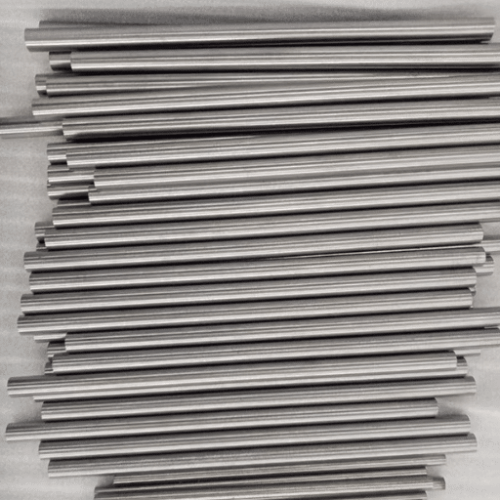

The 4j50 Iron Nickel Alloy Rod, also known as an invar rod, is recognized for its excellent thermal expansion properties and outstanding mechanical stability. It is primarily used in applications that demand minimal thermal expansion, such as precision instruments and aerospace components. Manufactured with high-quality materials, this alloy rod ensures reliability in critical industrial environments.

To inquire about pricing for our 4j50 Iron Nickel Alloy Rod, please contact us directly to receive a detailed quote. Pricing terms include bulk and custom orders.

The 4j50 Iron Nickel Alloy Rod serves a variety of industries, including but not limited to:

| Element | Percentage(%) |

|---|---|

| Nickel (Ni) | 49.5-50.5 |

| lron (Fe) | Balance(~48%) |

| Manganese (Mn) | ≤0.4 |

| Silicon (Si) | ≤0.3 |

| Carbon (C) | ≤0.05 |

| Phosphorus (P) | ≤0.02 |

| Sulfur (S) | ≤0.02 |

| Property | Value |

|---|---|

| Tensile Strength | 450-600 MPa |

| Yield Strength | ≥260 MPa |

| Elongation | ≥25% |

| Hardness | ≤200 HB |

| Environment | Corrosion Rate (mm/year) | Notes |

|---|---|---|

| Atmospheric | <0.01 | Excellent resistance to rust |

| Mild Acidic | 0.02-0.05 | Good performance in dilute acids |

| Alkaline | <0.01 | Highly resistant to alkalis |

| Seawater | 0.1-0.3 | Moderate, pitting risk in high chloride |

Contact us for detailed corrosion resistance data specific to your application.

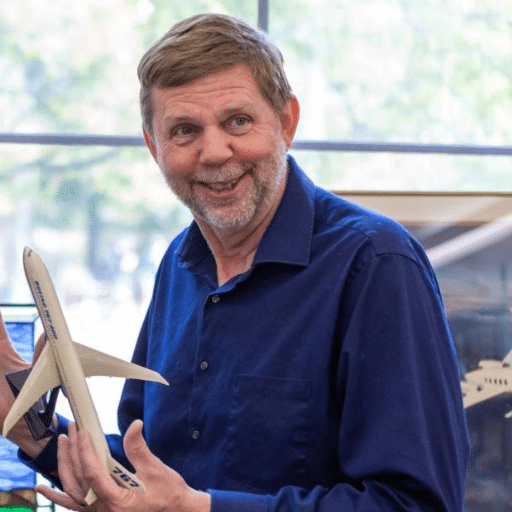

The 4J50 Iron Nickel Alloy Rod from this China manufacturer exceeded our expectations for precision and durability in satellite components.

John M.

Aerospace Engineer

Excellent invar bar for our relay production. Consistent quality and great corrosion resistance.

Sarah L.

Electronics Supplier

The alloy nickel and iron composition is spot-on, ensuring stable performance in our optical devices.

Mike T.

Precision Instrument Maker

A: The 4j50 alloy rod has a unique low thermal expansion property, making it ideal for precision applications compared to standard alloys.

A: Key industries include aerospace, electronics, and precision instruments manufacturing.

A: The alloy has a melting point of approximately 1430°C (2606°F).

A: Yes, we provide custom thicknesses, diameters, and lengths to meet unique requirements.

A: It offers good resistance to mild acids and atmospheric conditions, but prolonged exposure to harsh chemicals should be avoided.

Professional manufacturer of premium specialty alloys, offering stainless steel, Hastelloy, nickel-based alloys and processing services. Delivering superior metallurgical solutions for aerospace, petrochemical, marine engineering and other demanding industries.