Get in touch with us

Leave a message

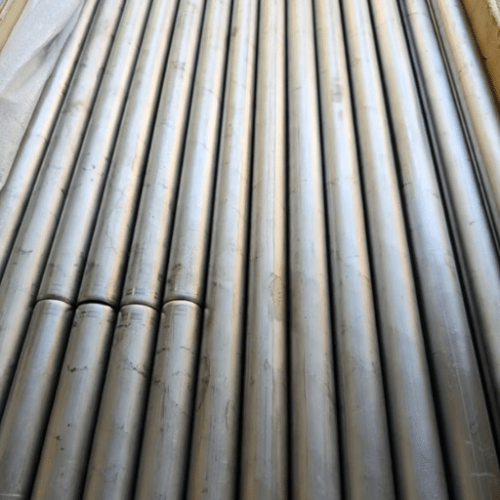

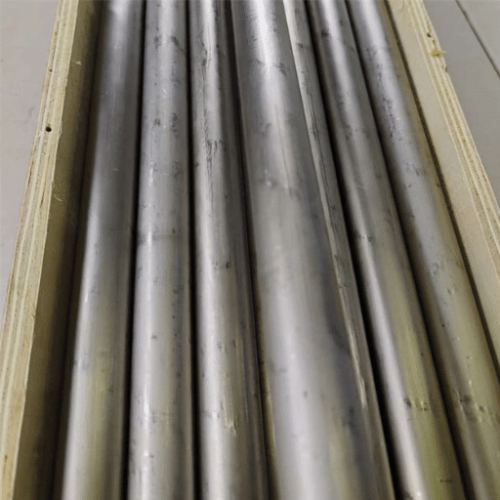

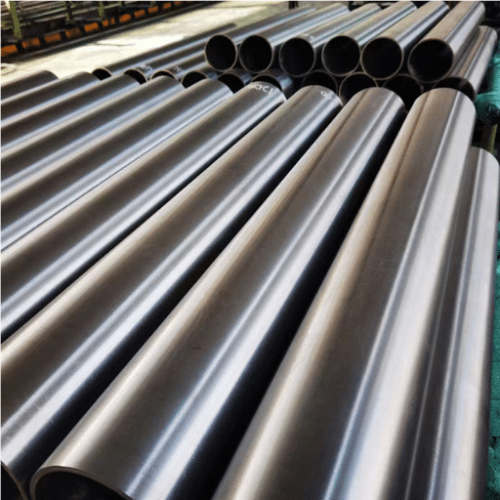

The 4J78 Iron Nickel Alloy Tube, a precision-engineered nickel-iron alloy, offers exceptional thermal stability and corrosion resistance. Known as an Invar material, it is ideal for applications requiring minimal thermal expansion, such as aerospace components and electronic devices. This high-performance alloy, produced by our trusted China manufacturer, ensures reliability in demanding environments.

For competitive pricing on 4J78 Iron Nickel Alloy Tube, contact our sales team for a personalized quote. Flexible terms available to meet your project needs.

The 4J78 Iron Nickel Alloy Tube excels in industries such as:

| Element | Percentage (%) |

|---|---|

| Nickel (Ni) | 35-80 |

| lron (Fe) | 20-65 |

| Molybdenum (Mo) | 0-5 |

| Copper (Cu) | 0-2 |

| Others | Trace |

| Property | Value |

|---|---|

| Tensile Strength | 550-750 MPa |

| Yield Strength | 200-400 MPa |

| Elongation | 30-40% |

| Hardness (HV) | 80-90 HV10 |

| Density | 8.1 g/cm³ |

| Environment | Corrosion Rate (mm/year) |

|---|---|

| Atmospheric (Urban) | <0.01 |

| Seawater (Flowing) | 0.02-0.05 |

| Sulfuric Acid (10%) | 0.01-0.03 |

| Phosphoric Acid (Commercial) | <0.02 |

Contact us for detailed corrosion resistance data specific to your application.

The 4j78 Iron Nickel Alloy Tube matched all our specifications and performed beyond expectations. Great quality!

John D.

Aerospace Engineer

This material has excellent magnetic properties. A reliable option for precision manufacturing.

Emily R.

Instrument Manufacturer

Consistent quality and durable—perfect for our electronic components production.

Li Q.

Electronics Supplier

A: Its high nickel content enhances magnetic and thermal properties, setting it apart from other alloys.

A: It is used in aerospace, electronics, and as magnetic shielding in various applications.

A: Yes, it can be manufactured to specific dimensions to meet various industrial needs.

A: Its chemical composition provides resistance against atmospheric and mild chemical exposure.

A: The approximate melting point is 1400°C, contributing to its impressive thermal resistance.

Professional manufacturer of premium specialty alloys, offering stainless steel, Hastelloy, nickel-based alloys and processing services. Delivering superior metallurgical solutions for aerospace, petrochemical, marine engineering and other demanding industries.