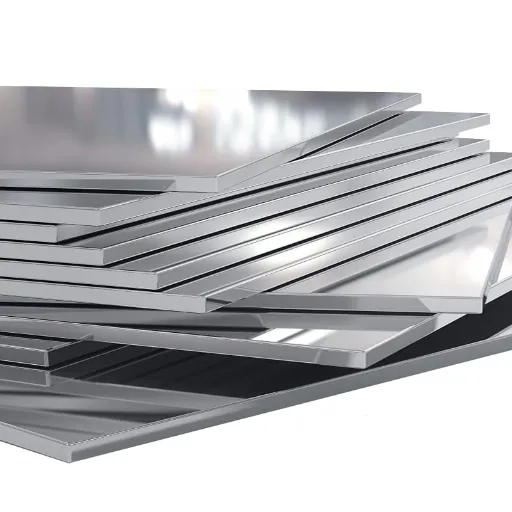

Stainless steel products are vital to our daily lives, found everywhere from building construction to automotive applications, kitchenware, and medical equipment. Their popularity stems from exceptional longevity, damage resistance, and clean aesthetic appeal. However, with different grades and types available, selecting the right stainless steel is crucial for optimal performance.

This comprehensive guide explores the world of stainless steel, focusing on commonly used grades like 430, examining their advantages, limitations, and key applications. Whether you’re a newcomer or experienced professional, this manual provides valuable insights for informed decision-making.

Understanding Stainless Steel: An Overview

Stainless steel is an iron-based alloy renowned for outstanding corrosion resistance. The addition of chromium creates the “stainless” property by forming a protective oxide layer when exposed to oxygen. Additional elements like nickel, molybdenum, and manganese can be incorporated to enhance specific properties including strength, durability, and chemical resistance.

Popular Stainless Steel Grades

| Grade | Type | Chromium Content | Nickel Content | Key Features |

|---|---|---|---|---|

| 304 | Austenitic | ~18% | ~8% | Excellent corrosion resistance, versatile applications |

| 316 | Austenitic | ~18% | ~10% | Enhanced corrosion resistance with molybdenum (2-3%) |

| 430 | Ferritic | ~17% | 0% | Cost-effective, magnetic, good formability |

The Importance of Steel Grades

Steel grades determine specific properties and applications, ensuring materials meet industry-specific environmental requirements. Classification typically focuses on corrosion resistance, strength, and structural characteristics, with austenitic and martensitic grades being the most popular categories.

- Austenitic grades (304, 316): Excellent corrosion resistance and formability

- Ferritic grades (430): Cost-effective with magnetic properties

- Martensitic grades (410): High strength and wear resistance

- Duplex grades (2205): Superior strength and corrosion resistance

Types of Stainless Steel

1. Austenitic Stainless Steel

The most popular category, representing approximately 70% of worldwide stainless steel production. These non-magnetic steels offer excellent corrosion resistance and formability.

- Superior corrosion resistance

- Non-magnetic properties

- Excellent formability and weldability

- Common grades: 304, 316

2. Ferritic Stainless Steel

Contains 10.5-30% chromium with low carbon content. These magnetic steels offer good corrosion resistance at lower costs than austenitic grades.

- Magnetic properties

- Cost-effective alternative

- Good thermal conductivity

- Common grades: 409, 430

3. Martensitic Stainless Steel

Known for superior strength and hardness, containing 0.1-1.2% carbon and minimum 12% chromium. Ideal for high-wear applications.

- High strength and hardness

- Heat treatable

- Good wear resistance

- Common grades: 410, 420

4. Duplex Stainless Steel

Combines austenitic and ferritic structures, offering nearly double the strength of standard austenitic grades.

- High strength-to-weight ratio

- Excellent stress corrosion cracking resistance

- Superior pitting resistance

- Common grades: 2205

5. Precipitation-Hardening Stainless Steel

Achieves high strength through controlled addition of elements like aluminum or copper.

- Exceptional mechanical properties

- Heat treatable for increased strength

- Aerospace and defense applications

- Common grades: 17-4PH (630)

Grade 430 Stainless Steel: Practical Applications

Grade 430 is widely used in kitchen appliances, automotive trim, and interior architectural applications due to its corrosion resistance and attractive appearance. It’s particularly suitable for applications requiring basic corrosion protection with cost considerations.

Industries Utilizing 430 Stainless Steel

1. Automotive Industry

Applications: Exhaust systems, trim components, decorative elements

Benefits: Excellent oxidation resistance, durability, low maintenance requirements

Market Outlook: Demand projected to grow over 5% by 2030

2. Home Appliances

Applications: Refrigerator doors, oven liners, dishwasher interiors

Benefits: Attractive finish, easy cleaning, heat resistance

Market Share: Approximately 20% of global stainless steel consumption

3. Construction and Architecture

Applications: Building cladding, roofing systems, architectural features

Benefits: Corrosion resistance, polished finish, structural integrity

Market Growth: 4% annual growth rate in construction applications

4. Industrial Equipment

Applications: Mild chemical environments, moderate-temperature applications

Benefits: Good machinability, scaling resistance, cost-effectiveness

5. Electronics

Applications: Component enclosures, transformer casings

Benefits: Magnetic properties provide additional utility

Case Studies: 430 Stainless Steel Success Stories

Case Study 1: Automotive Exhaust Systems

Challenge: Reduce production costs while maintaining performance standards

Solution: Implementation of 430 stainless steel in exhaust systems

Results:

- 15% reduction in production costs

- Maintained rigidity and performance standards

- Enhanced sustainability goals achievement

Case Study 2: Kitchen Appliance Manufacturing

Challenge: Balance affordability with durability in consumer appliances

Solution: Transition to 430-grade stainless steel for key components

Results:

- 20% increase in demand since 2022

- 12% cost savings compared to traditional steels

- Improved manufacturing efficiency

Case Study 3: Commercial Building Cladding

Challenge: Achieve contemporary aesthetics with long-term durability

Solution: 430 stainless steel cladding system implementation

Results:

- 30% reduction in maintenance costs over 20 years

- Superior weather resistance performance

- Enhanced building aesthetic appeal

Benefits and Limitations of 430 Stainless Steel

✅ Advantages

- Cost-Effective: Up to 25% less expensive than 304 grade

- Good Corrosion Resistance: Suitable for moderate environments

- Magnetic Properties: Useful for specific applications

- Easy Formability: Good ductility for manufacturing

- Attractive Finish: Polished surface appeal

❌ Limitations

- Lower Corrosion Resistance: Compared to austenitic grades

- Welding Challenges: Prone to cracking and heat-affected zones

- Limited Ductility: Less formable than austenitic steels

- Temperature Limitations: Not suitable for high-temperature applications

- Marine Environment Issues: Susceptible to pitting in coastal areas

Technical Specifications

| Property | Grade 430 | Grade 304 | Grade 316 |

|---|---|---|---|

| Yield Strength | 205 MPa | 205 MPa | 205 MPa |

| Tensile Strength | 450 MPa | 515 MPa | 515 MPa |

| Magnetic Properties | Magnetic | Non-magnetic | Non-magnetic |

| Corrosion Resistance | Good | Excellent | Superior |

| Cost Relative to 304 | 75% | 100% | 125% |

Reference Sources

- The Federal Group USA: Different Types of Stainless Steel

This source discusses the properties of Grade 430 stainless steel, including its resistance to nitric acid and its applications in various industries.

Source - SPP USA: Types and Grades of Stainless Steel

This article provides an overview of Type 430 stainless steel, highlighting its corrosion resistance and suitability for specific applications.

Source - MetalsCut4U: Types of Stainless Steel

This blog explains the common uses of Grade 430 stainless steel, such as in appliance trim, automotive trim, and architectural panels, emphasizing its good corrosion resistance.

Source

Frequently Asked Questions (FAQ)

Grade 430 is a ferritic stainless steel known for excellent corrosion resistance, adequate strength, and superior formability. Chromium serves as the principal alloying element, providing corrosion-resistant properties ideal for applications balancing aesthetic appeal with functionality.

Grade 430 is ferritic while 304 is austenitic. Grade 304 contains nickel, providing better corrosion properties and superior ductility, making it suitable for food processing and chemical applications. Grade 430 is more cost-effective for less corrosive environments.

Yes, stainless steels include ferritic, martensitic, duplex, and austenitic types, each with distinguishing features. Austenitic grades (304, 316) showcase excellent corrosion resistance, while ferritic grades (430) are magnetic with good formability at lower costs.

430 stainless steel features a yield strength of approximately 205 MPa and tensile strength of about 450 MPa. It exhibits acceptable ductility and formability, making it suitable for diverse fabrication processes.

Yes, but welding grade 430 requires specific techniques to maintain corrosion resistance and prevent cracking. It’s advisable to use appropriate filler materials and consider passivation treatment to preserve the material’s corrosion resistance properties.

Grade 430 is widely used in automotive, kitchen equipment, industrial design, cutlery manufacturing, and decorative applications. Its combination of mild corrosion resistance, aesthetic appeal, and cost-effectiveness makes it ideal for these industries.

Conclusion

Grade 430 stainless steel represents an excellent balance of performance, cost-effectiveness, and versatility across multiple industries. While it may not offer the superior corrosion resistance of austenitic grades like 304 or 316, its unique combination of properties makes it an ideal choice for applications where moderate corrosion resistance, magnetic properties, and cost considerations are paramount.

Understanding the specific requirements of your application—including environmental conditions, mechanical stress, and budget constraints—is crucial for making informed decisions about stainless steel grade selection. As industries continue evolving toward more sustainable and cost-effective solutions, Grade 430 stainless steel remains a valuable option in the comprehensive stainless steel family.