Get in touch with us

Leave a message

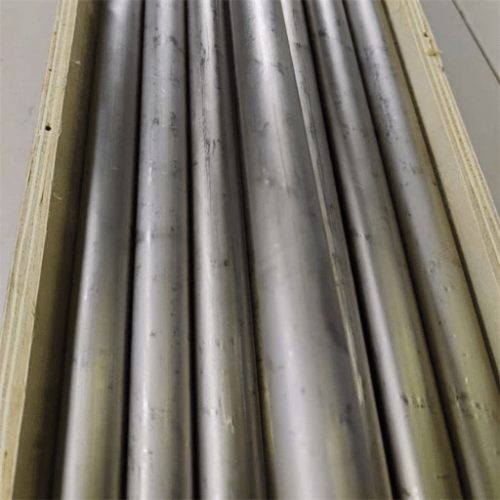

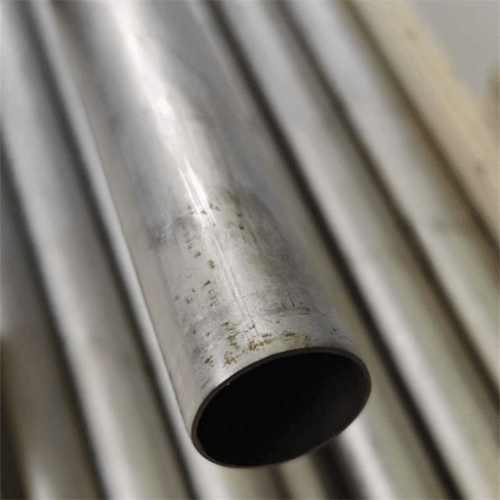

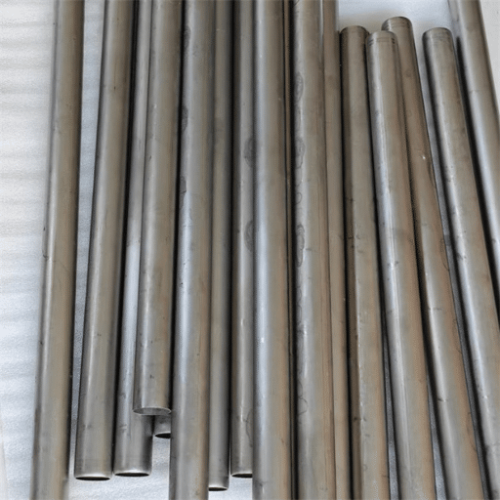

The 4j29 Iron Nickel Alloy Pipe, also known as Invar material, is a precision-engineered nickel-iron alloy renowned for its low thermal expansion and exceptional dimensional stability. Manufactured in China, this alloy pipe is ideal for applications requiring high precision and resistance to environmental changes. Its unique nickel iron alloy properties make it a top choice for industries like aerospace, electronics, and scientific instrumentation.

For pricing information regarding the 4j29 Iron Nickel Alloy Pipe, please reach out to us directly to receive a customized quote. Pricing terms and conditions can vary depending on specifications and order volumes.

The 4j29 Iron Nickel Alloy Pipe is widely used across industries:

| Element | Percentage (%) |

|---|---|

| Nickel (Ni) | 35.0-37.0 |

| lron (Fe) | Balance |

| Manganese (Mn) | ≤0.5 |

| Silicon (Si) | ≤ 0.3 |

| Carbon (C) | ≤ 0.05 |

| Sulfur (S) | ≤ 0.02 |

| Phosphorus (P) | ≤ 0.02 |

| Property | Value |

|---|---|

| Tensile Strength | 450-550 MPa |

| Yield Strength | 240-300 MPa |

| Elongation | ≥30% |

| Hardness (HB) | 120-150 |

| Density | 8.1 g/cm³ |

| lron Nickel Alloy Melting Point | 1427°C |

| Environment | Corrosion Rate (mm/year) |

|---|---|

| Atmospheric (Rural) | <0.01 |

| Atmospheric (Marine) | 0.01-0.03 |

| Mild Chemical (pH 5-9) | <0.02 |

| Dilute Acid (10% H₂SO₄) | 0.05-0.1 |

Contact us for detailed corrosion resistance data specific to your application.

For welding, the 4j29 Iron Nickel Alloy Pipe is compatible with TIG and MIG welding techniques. It supports conventional machining and forming processes, making it versatile for various fabrication needs. Preheating and post-weld heat treatment are recommended to ensure optimal performance.

The 4j29 Iron Nickel Alloy Pipe from this China manufacturer exceeded expectations. Its low thermal expansion is perfect for our satellite components.

John S.

Aerospace Engineer

Reliable and easy to machine into Invar bar. The corrosion resistance is a game-changer for our circuit supports.

Emily R.

Electronics Manufacturer

These pipes handle harsh pipeline conditions well. Great quality from a trusted distributor.

Michael T.

Energy Sector

A: Its primary uses include housing and sealing in electronics, aerospace components, and precision medical device manufacturing.

A: The 4j29 alloy features a specific nickel-iron balance that ensures low thermal expansion, making it ideal for high-precision applications.

A: It holds up well in mild corrosive environments but is not recommended for use in highly acidic or harsh chemicals without protective measures.

A: The thermal expansion rate is approximately 9.2 x 10⁻⁶/°C between 20°C and 200°C, ensuring stability over temperature variations.

A: Please contact us directly with your specific requirements, and our team will assist you in customizing the product to meet your needs.

Professional manufacturer of premium specialty alloys, offering stainless steel, Hastelloy, nickel-based alloys and processing services. Delivering superior metallurgical solutions for aerospace, petrochemical, marine engineering and other demanding industries.