Working with stainless steel can be a double-edged sword, it can be both rewarding and challenging. It doesn’t matter if you’re a professional metalworker or a DIY enthusiast trying to get your next big project done, knowing how to cut stainless steel properly is paramount. The material is, of course, very durable, versatile, and has outstanding properties so that it is a preferred choice for a multitude of applications. Nevertheless, its very durability can sometimes be a hindrance if the wrong techniques and tools are used. We are going to discuss in this article the best practices, tools, and safety tips for cutting stainless steel like a pro. The guide will enable you to take on any project involving cutting of stainless steel with assurance, as it covers beginner-friendly methods to advanced techniques.

Cutting Stainless Steel – An Introduction

The cutting of stainless steel a very effective way requires the selection of the appropriate tools to cut the material, which may be an angle grinder, circular saw, or plasma cutter, depending on the complexity of the project. In addition to that, I wear the proper safety gear, like gloves and goggles, and, to get clean results, I also take my time to draw very accurate cutting lines.

The Need for Cutting Stainless Steel

Cutting stainless steel is a major operation in many industries such as construction, automotive, and manufacturing which mainly use its versatility and durability. The main reason for the popularity of stainless steel is its resistance to rust, high and extreme temperature as well as chemical attack hence it becomes a very important material for various applications. But at the same time, it is strong and dense which poses a challenge of difficult cutting and accurate shaping of it.

Industry Insight: As per the latest reports from the industry, the global production of stainless steel surpassed the 58 million metric ton mark in 2022, which indicates the high demand for this metal across various sectors. Adoption of precision cutting techniques is critical to material integrity and waste reduction, as incorrect cuts can result in costly material defects or structural weaknesses. The development of technology in laser cutting and waterjet cutting has allowed the attainment of very precise results with an accuracy of ±0.005 inches in some cases, depending on the cutting method employed.

The Application Areas of Cut Stainless Steel – An Overview

Stainless steel, which is known for its strength, resistance to corrosion and nice look, is very much used in different sectors because of its vast applications. DIY enthusiasts use cut-to-size stainless steel in making custom furniture, decorative wall panels, kitchen backsplashes, and hand-crafted tools. Such projects often require a combination of precision and creativity to cut the material in such a way that both aesthetic and functional attributes are shown off.

On the side of industry, professional metalworkers go for cut metal to support them in their work in construction, automotive manufacturing, aerospace, and medical device production. As per the recent statistics, the global stainless steel market was around $111.4 billion at the end of the year 2022 with segments like buildings and infrastructure (about 35%) and the automotive industry (nearly 20%) being the main contributors to this demand. Stainless steel’s property of enduring tough conditions and losing none of its strength through heat makes it a vital material for the structure of future buildings, making it the right choice for the manufacture of exhaust systems and heavy-duty components in machinery, amongst other things.

Methods of Cutting Stainless Steel

Expert Tip: In my experience, when selecting a method for cutting stainless steel, it is always best to consider the project requirements first. For laser cutter and plasma cutter were the tools of choice for precision cuts. But on the other hand, if the factors of weight and cost-efficiency were more pressing, then, grinder or saw with a special blade would have been the way to go.

Laser Cutting: Precision and Efficiency

Laser cutting has been one of the preferred stainless steel cutting methods because of its outstanding precision, efficiency, and versatility. This process uses a highly focused energy laser beam and can also make very complicated and elaborate cuts without practically damaging the material around the cut. In fact, the process can be done with tolerances as fine as ±0.001 inches, making it perfect for extremely accurate applications.

The newest laser cutting technology is incredibly efficient, which leads to less material waste and lower production costs. In the last year, laser cutting machines with the above-mentioned maximum speeds have been technicallly 20 meters per minute in quarter inch, and lots of the manufacturers whose products are affected by thickness and quality only. For instance, fiber lasers are the choice for cutting sheets of thin stainless steel for they are actually faster than CO2 feature lasers.

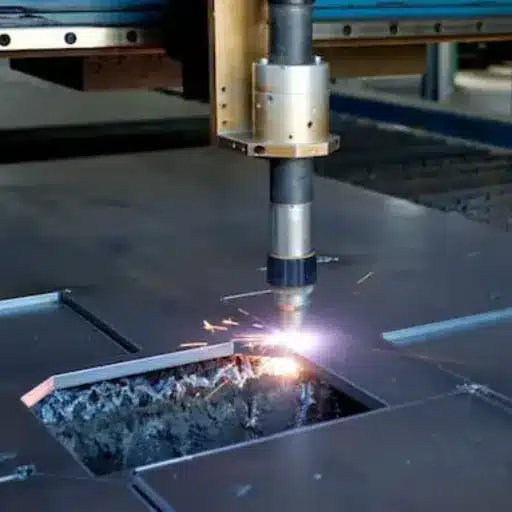

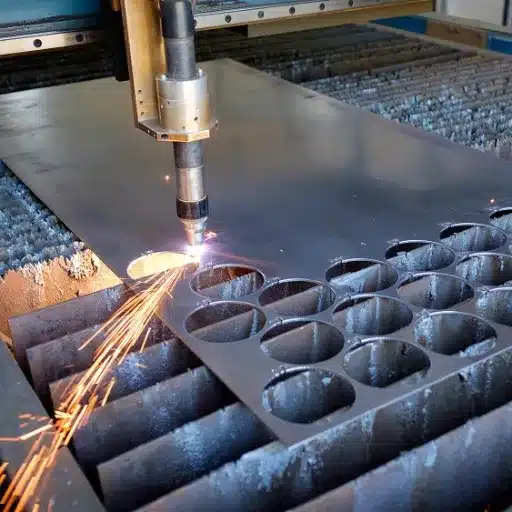

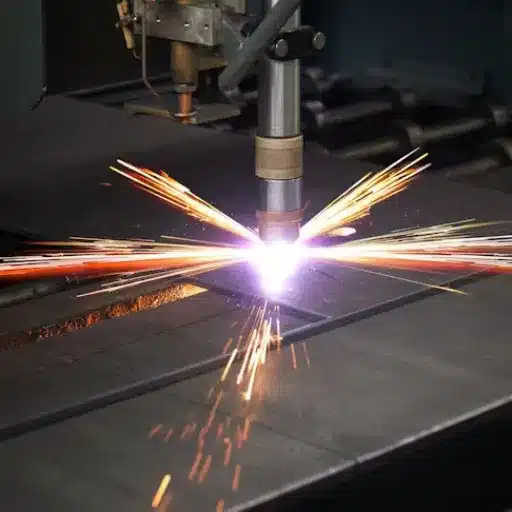

Plasma Cutting: Speed and Versatility

Plasma cutting is at the peak of the metal fabrication industry due to its high versatility and efficiency, and thus, it is very widely used. The method functions by blasting an electric current through a gas that is then cut by a hot high-velocity jet of plasma, which can dissolve such materials as stainless steel, aluminum, and mild steel. The process is fast and very efficient as one of the main advantages of plasma cutting, it can cut through materials, that are as thick as 50mm, at rates that are much faster than mechanical cutting methods. Thus, it is quite suitable for high-volume production environments.

Today’s plasma cutting systems are not only fast but very precise, as they can produce tight tolerances and clean edges which will short the further processing. Moreover, automated plasma cutting systems have increased cutting speeds and operators of expensive CNC-controlled plasma modern systems have developed economies in costs and gains in productivity. According to some reports, the current generation of plasma cutters can reach cutting speeds of 500 IPM (inches per minute) even on thin materials, thus keeping turnaround times short, even on intricate designs.

Pros and Cons of Each Cutting Technique

✓ Advantages of Laser Cutting

Laser cutting is a technology that is known for its precision and versatility and hence is a highly preferred option in the manufacturing sector from the automotive to the aerospace industry. One of the most important benefits of laser cutting is its ability to make very fine and smooth cuts with tolerances of as small as ±0.001 inches. The accuracy level that is so high makes it possible to save the costs of processing and recovering the waste that would be lost if laser cutting was not used.

Moreover, laser cutting is a process that can work with different kinds of materials like metals, plastics, wood, and glass, so it is very easy for the manufacturers to work with different applications. In comparison with the traditional cutting methods, laser cutters got the skill to go through complex geometries and intricate designs and pump out detailed components.

✗ Disadvantages of Plasma Cutting

On the one hand, plasma cutting is a highly efficient and widely used method to cut through metals but on the other hand, it comes with a number of disadvantages that can make it unfit for certain applications. The first disadvantage that comes to mind is the lower degree of precision and edge quality plasma cutting compared to laser cutting. The plasma cutting method is notably less accurate when working with very thin materials, often resulting in rough edges that would need additional post-processing anyway.

Another major setback of the process is the higher amount of noise and smoke that is generated during the operation. The thermal cutting of metals with plasma involves a huge amount of heat and plasma channels which in turn produce gas and smoke that can be harmful to human beings if a proper ventilation system is not in place along with wearing the correct personal protective equipment. Besides, the energy requirements of the process can be considerable consuming hence the eventual electricity bills and the operational costs will keep rising over time.

Safety Tips for Cutting Stainless Steel

⚠️ Safety First: One of my main priorities when cutting stainless steel is to wear suitable personal protective equipment, which includes gloves, safety goggles, and a welding helmet. I always make sure that the area I work in is well-ventilated or I use fume extraction systems to cut down on my exposure to harmful gases.

Personal Protective Equipment (PPE) for Cutting Stainless Steel

🥽 Protective Eyewear or Face Shields

The process of cutting stainless steel releases sparks and sharp metal pieces, which can cause serious harm to the eyes and face. The usage of safety goggles that follow ANSI Z87.1 standards or full-face shields provides the best defense against the debris that is blown around. It has been reported that nearly 90% of eye injuries sustained in industrial environments can be prevented with the correct use of protective eyewear.

🧤 Cut-Resistant Gloves

The edges of stainless steel can be extremely sharp, and cuts can occur easily. Cut-resistant gloves, which are normally made from materials like Kevlar or Dyneema, offer great protection while still allowing the hand to move freely. It is a well-accepted fact that 23% of all work-related injuries are hand injuries, therefore adequate hand protection is necessary.

🎧 Hearing Protection

The loud cutting process, particularly through the use of power tools, produces noise that may reach up to and exceed 85 decibels, which can eventually lead to auditory damage. Someone working in such a noisy environment needs to use either earplugs or earmuffs with a sufficient noise reduction rating (NRR) to prevent experiencing hearing loss over the long run.

Safe Handling of Tools and Materials

Proper handling of tools and materials is the key to having a safe and productive work environment, especially in working with stainless steel. Mishandling can cause accidents that result in serious injuries, destruction of the equipment, and hence less productivity. Tool and materials mishandling is among the factors that OSHA indicates as major bits of workplace injuries, sharing in about 30% of all the reported cases in the industry.

While using cutting tools, the workers need to make sure that regular inspections are done to spot any wear or damage to the tools. The risk of accidents like broken blades or sudden tool malfunctions is increased by using defective tools. Moreover, tools should be properly placed in specific areas to avoid the possibility of unauthorized access to them and the corresponding hazards. Tools designed with ergonomics in mind can also lessen the physical stress imposed on the workers and thereby mitigate the incidence of repetitive motion injuries.

Essential Tools for Cutting Stainless Steel

Professional Insight: Stainless steel cutting is my work and I also use some indispensable tools like angle grinders, carbide blade circular saws and plasma cutters. Depending on the thickness and type of cut required, every tool is giving me the same precision and efficiency.

Overview of Cutting Tools for Stainless Steel

1

Angle Grinders

Among the tools used, angle grinders are the most recommended and one of the most versatile cutting tools for stainless steel sheets and bars. If one uses a cutting disc of metal quality, then cutting will be efficient and smooth. The modern day has seen the introduction of the zirconia alumina discs which are the most recent advancement in the technology of the cutting discs. These discs have a longer life and a faster cutting rate. A study says that the life of these advanced discs can be reduced to 30% in terms of cutting time in comparison to older models.

2

Circular Saws with Carbide-Tipped Blades

For straight and precise cuts, carbide tipped circular saws are the best choice. The main difference between carbide and steel is that carbide can withstand heat more than steel can, hence the carbide blades can be used for a longer duration without losing its sharpness. There are blades that are specially made for stainless steel from the manufacturers and this results in giving the joining of the materials cleaner edges and less vibration. The efficiency has been reported to have risen by 15% owing to this development in very recent tool performance reviews.

3

Plasma Cutters

Plasma cutters work by using the high temperature ionized gas to cut the stainless-steel pieces from the thicker ones, and the tool can cut through them quickly. This tool is mainly for the professionals who deal with industrial stainless steel. An industry report mentioned in 2022 that the combination of modern plasma cutters with CNC tech can achieve precision cuts with tolerance as low as ±0.1 mm, thus being the go-to tools for detailed projects.

Professional Equipment for Metalworkers

Metalworking is a precision craft that needs specialized tools to be able to get accurate and efficient results, and thus, precision tools are a must in every metalworking shop. Modern professional carving tools are built to save process time, improve safety, and better the quality of finished products. One major tool for the metal worker is the CNC machine (Computer Numerical Control), which permits the accurate cutting, drilling, and shaping of metal materials. Gradual adoption of CNC machines has been seen, and for that reason, it is reported that production efficiency can be improved by as much as 50% in comparison with using the traditional manual methods.

Welding machines are another must-have tool; especially MIG and TIG welders, which are highly regarded for their power and reliability in metal parts joining. To illustrate, the TIG type provides high precision which is ideal for thin materials and complex designs. The worldwide market for welding equipment was $13.1 billion in 2022, and it is projected to grow at the annual rate of 4.1%, which is the indicator of the increasing demand for advanced welding technologies.

Reference Sources

-

Free Cutting Stainless Steel Market Size 2026-2033

This source discusses the segmentation of the free-cutting stainless steel market, including demographics, geography, product types, applications, and end-users. It provides insights into the market demand and applications, which can validate the feasibility of targeting specific audiences. -

Taking Stainless Steel Machining to the Next Level – SME

This article focuses on the technical aspects of machining stainless steel, including the importance of using machines with adequate horsepower and torque. It highlights the practical considerations and challenges, making it a reliable source for understanding the feasibility of cutting stainless steel. -

What is Stainless Steel Target? Uses, How It Works & Top Companies

This source explains the industrial applications of stainless steel, including its use in manufacturing, welding, and surface treatments. It provides context on the end-user industries and their requirements, supporting the feasibility of targeting these audiences.

Frequently Asked Questions (FAQs)

❓ In what manner can I cut stainless steel sheet so that the cutting does not damage it?

To perform the cutting of a stainless steel sheet without ruining it, utilize a cutting tool that offers exact and fine control, like a laser cutter or a circular saw with the proper blade. It is very important to keep low blade speed and correct cutting pressure to prevent warping or influencing the material’s resistance to corrosion. A clamps setup could provide support by holding the sheet in place during the cutting operation.

❓ Is it possible to use a hacksaw for the cutting of thick stainless steel?

The answer is affirmative; a hacksaw can be used in case of cutting thick stainless steel but it will take more effort and time than cutting with other tools. For cleaner cuts, a hacksaw blade with a higher number of teeth per inch is suggested. However, if the stainless steel is extremely thick, a bandsaw or a cutting torch may be a better option.

❓ What are the right tools to cut stainless steel rods?

Among the tools that can be considered the best for cutting stainless steel rods are a band saw or a chop saw fitted with a metal cutting blade. A grinder with a cutting wheel might also work for cutting smaller pieces. Make sure you pick a tool that will be able to cope with the rod’s thickness and also employ proper cutting techniques to ensure straight cuts.

❓ How does 304 stainless steel compare with other metals in the context of cutting?

It is the characteristic of 304 stainless steel to resist corrosion effectively, besides, it is a metal that is easier to cut than carbon steel, for instance. Nevertheless, it will still present the issue of toughness cutting. The use of the correct tools and methods, such as a laser cut or a plasma cutter, can make the cut less challenging than cutting process with mildest metals.

❓ What are the primary techniques for stainless steel cutting?

The primary techniques for stainless steel cutting are a band saw, plasma cutter, laser cutter, and circular saw. Each of these methods has its pros and cons and can be used for different thicknesses and applications. For instance, if a high precision is needed, then the laser cutter will be employed, whereas, cutting torch will be used for thicker materials.

Ready to master stainless steel cutting?

Armed with the right tools, techniques, and safety knowledge, you’re now prepared to tackle any stainless steel cutting project with confidence and precision.