Knowing the melting point of stainless steel is of great importance for professionals operating in the industries of production, engineering, or metallurgy. This and many other features made stainless steel one of the most popular materials. So, what will happen if extremely high temperatures are applied? The article will give you a thorough explanation of melting point of stainless steel in Celsius, and at the same time it will reveal different factors that affect it and will also discuss the effect of various alloys and their composition through the process of melting under super heating conditions. A detailed professional in your area or just curious about the metal’s science, this all-round guide is for you.

Understanding the Melting Point of Stainless Steel

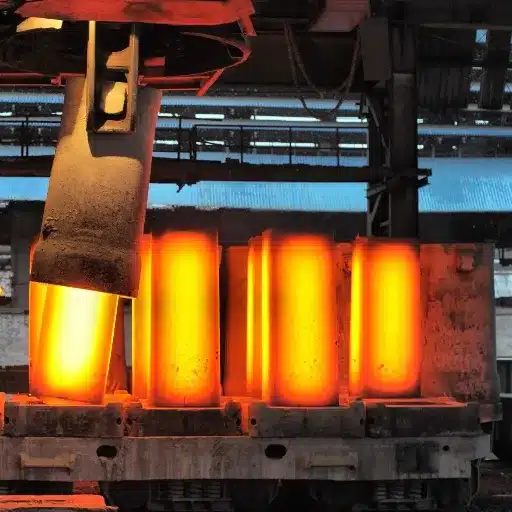

Stainless steel starts melting at a temperature of about 1,370°C to 1,530°C when extremely high temperatures are applied. The melting point of stainless steel in specific ranges depends on its alloying elements, particularly the amounts of chromium, nickel, and carbon in it.

Definition and Composition of Stainless Steel

Stainless steel is an alloy that is very versatile and very resistant to corrosion. Its main component is iron, and it has at least 10.5% of chromium by mass as the minimum. The presence of chromium is a significant factor in the creation of a protective layer of chromium oxide, which is impervious to rust and staining, on the surface of the material. Moreover, the composition of stainless steel may also include small amounts of other metals, such as nickel, molybdenum, carbide, and manganese, all of which are added to improve certain properties like strength, ductility, or extreme temperature resistance.

There are different types of stainless steel that are classified based on their chemical composition and crystalline structure:

Austenitic Stainless Steel

It has the highest level of chromium and nickel compared to others and also provides excellent resistance to rust and is very versatile. The most commonly used grades in this category are 304 and 316.

Ferritic Stainless Steel

It has more chromium and less nickel than the austenitic type, offering good corrosion resistance as well as higher thermal conductivity. Grades like 430 and 409 are typical for this type.

Martensitic Stainless Steel

This type is characterized by high carbon content, thus it is being considered for applications like cutlery and tools, which require hardness and strength.

Duplex Stainless Steel

This type has to mixtures of austenitic and ferritic properties, thus, it carries high strength and corrosion resistance, and is often used in chemical and marine environments.

Melting Point of Stainless Steel: Overview

The melting point of stainless steel is mainly dependent on its exact grade and alloy composition. In general, it is around 1,370 – 1,530°C (2,500 – 2,790°F) range. The exact melting temperature is determined by the mix of iron and the percentage of chromium, nickel, and carbon, as well as other additives which improve the stainless steel’s properties of strength, corrosion resistance, and durability.

| Stainless Steel Grade | Melting Point Range (°C) | Melting Point Range (°F) | Special Properties |

|---|---|---|---|

| 304 | 1,400 – 1,450 | 2,550 – 2,640 | Most commonly used grade |

| 316 | 1,375 – 1,400 | 2,507 – 2,552 | Contains molybdenum for harsh environments |

| 310 | Up to 1,500 | Up to 2,732 | Extreme temperature applications |

Factors Influencing the Melting Point

Alloying Elements and Their Impact

CrChromium (Cr)

Being one of the main components in stainless steel, chromium not only increases corrosion resistance but also expands oxidation resistance at high temperatures. The melting point of an alloy is elevated a little bit due to the presence of chromium, which helps in developing the protective oxide layer as well.

NiNickel (Ni)

Nickel fortifies durability and corrosion resistance all the more, especially in reduction environments. Even though nickel addition reduces the melting range, it remarkably increases ductility and the thermal expansion tolerance of the material.

MoMolybdenum (Mo)

Molybdenum is the element that transforms stainless steel into a more reliable material by imparting higher hardness and strength as well as allowing to pitting and crevice corrosion resistance in chloride environments. The melting points are slightly affected by its presence, however, molybdenum’s properties of resistance to corrosion at high temperatures make it a must-have in harsh conditions.

CCarbon (C)

Even minor amounts of carbon can have a huge impact on the hardness and strength of stainless steel especially in martensitic grades. On the contrary, higher carbon content leads to a decrease in melting point, as in carbon-rich steels.

SiSilicon (Si)

Silicon, which is mostly used in top-quality steels, plays the role of a deoxidizer and is the one that gets rid of oxygen from metal making it more resistant to rust and it can even slightly increase the melting range with its presence. That is definitely the case for the alloys that will be subjected to high-temperature applications.

MnManganese (Mn)

Manganese enhances the hot working properties and it plays the role of deoxidizing during steel production at the same time. Its presence in the alloy invariably reduces the melting point but at the same time, it endows the steels with toughness and wear resistance.

NNitrogen (N)

Nitrogen continues to be the element that strengthens austenitic stainless steels by allowing for the creation of stronger bonds, even under harsh conditions. The presence of nitrogen does not have a significant impact on melting temperature; however, it does boost resistance to localized corrosion.

The Importance of Chromium and Other Metals

Among the metals, chromium is the one that significantly improves the overall quality of the alloy, particularly in the area of resistance to corrosion and oxidation where it is mainly the case. The oxidation and corrosion resistance of the alloys are made by the oxides that are formed on the surface of the alloys that are well protected from degradation by the environment. At least 10.5% chromium content in stainless steels which is the minimum is required to get their claim to fame—their being rust-proof and stain-free—great resistance to rust and staining. Besides, chromium is also included in the hardness of the alloys and is credited with the high-temperature strength of the alloys, thus it being a structural application where the extreme conditions are the part getting best out of it.

Chromium is often used with other metals like nickel and molybdenum for superior performance. On the one hand, nickel mainly improves toughness and ductility, which means that the alloy can withstand the applied stress without being damaged. On the other hand, molybdenum improves the resistance to pitting and crevice corrosion, in particular, environments that are rich in chlorides. For example, in the case of superalloys for aerospace turbines, a combination of up to 20% nickel and 6% molybdenum with chromium is quite common in order to achieve the ultimate temperature of 1,000°C (1,832°F) while at the same time being able to support an enormous amount of mechanical load.

Melting Points of Metals: A Comparative Analysis

I am sure that the mix of nickel and molybdenum brings a lot of superalloys up to the notch. Nickel is important for its toughness and ductility, which are the main characteristics at the point of maximum stress, while molybdenum particularly in the harshest environments offers the best resistance to corrosion.

Melting Temperature Range of Common Metals

| Metal | Melting Point (°C) | Melting Point (°F) | Common Applications |

|---|---|---|---|

| Aluminum (Al) | 660 | 1,220 | Aerospace, automotive, casting |

| Gold (Au) | 1,064 | 1,947 | Electronics, jewelry |

| Copper (Cu) | 1,084 | 1,983 | Electrical, thermal conductivity |

| Stainless Steel (304) | 1,400 – 1,450 | 2,552 – 2,642 | Construction, food industry |

| Nickel (Ni) | 1,455 | 2,651 | Gas turbines, aircraft engines |

| Iron (Fe) | 1,538 | 2,800 | Steel production |

| Titanium (Ti) | 1,668 | 3,034 | Aircraft, medical applications |

| Tungsten (W) | 3,422 | 6,192 | Light bulbs, high-temp furnaces |

Practical Applications of Melting Point Knowledge

Melting points play a great role in my selection of materials for different applications where the resistance against high temperatures is a necessity. For example, by knowing the melting points of molybdenum and iridium, I can use them in very hot places like furnace parts or electrical contacts which will be both durable and performing well.

Importance in Industrial Processes

The melting point of a substance is one of the key characteristics that greatly influence its various industrial applications. For example, the aerospace industry mainly uses metals with melting points that are incredibly high, such as tungsten (3422°C) and molybdenum (2623°C), because of their capability of keeping the structural integrity even in very high-temperature conditions. The use of such substances for the production of rocket nozzles and heat shields exemplifies the fact that sometimes in an industry heat resistance is paramount, and these metals have the desired qualities to withstand such conditions.

Depending on the alloy, stainless steel has a melting range of approximately 1370-1530°C and is differentially used in the construction of infrastructure, the manufacturing of machines, and even the production of utensils in the kitchen. The melting point height along with corrosion resistance has made it one of the prime materials for the aforementioned applications carrying the benefits of durability and cost-effectiveness. On the contrary, aluminum with a relatively low melting point of around 660°C has found application mostly in the automotive and packaging sectors where lightweight yet strong materials are required.

Applications in Stainless Steel Products

Stainless steel, a material that is highly resistant to corrosion and has a long life, is very versatile due to the control of its melting point during production. The melting points of different types of stainless steels range from 2,500°F to 2,800°F (about 1,370°C to 1,540°C) and this depends on the alloy composition. Ther e m ore, world-class metal companies take advantage of the latest metallurgical techniques and improve the melting and casting processes of stainless steel, so as to make the best quality products for different industries.

One of the first industries is construction, where stainless steel is extensively used for structural members, facades, and reinforcements. The material’s high melting point allows it to retain its strength in harsh conditions. The food and drink industries are also getting benefits from low maintenance stainless steel products such as kitchenware and equipment; thanks to its hygienic properties and resistance to dying through sterilization.

Melting Points: Misconceptions That Should Be Corrected

Common Misconception: One of the most common misconceptions about melting points is that a high melting point always indicates an invincible material or one that cannot be damaged at all. Certainly, a high melting point is an indicator of the material’s being less affected by heat, but it does not necessarily suggest that heat is the only factor the material is resistant to; it may also be resistant to other factors such as corrosion, mechanical wear, and chemical reactions.

Steel and Its Corrosion Resistance: Major Misunderstandings

One of the widespread misconceptions is that, in every situation, stainless steel is stronger than carbon steel. Though the former is excellent in resisting rust, the latter is often more resilient in terms of hardness and strength. For instance, the tensile strength of high-carbon steel can be as high as 1,200 MPa (megapascals), whereas the strength of standard stainless steels like 304 or 316 grades usually falls between 485 and 620 MPa averaging. This makes carbon steel a material of choice wherever extreme hardness is required, e.g., in cutting tools or machinery components.

Another misconception is regarding their high-temperature performance. Stainless steel, being able to withstand higher melting temperatures, usually between 1,375 and 1,530°C (2,507 to 2,786°F), may still lose its mechanical characteristics after being subjected to that heat for long periods. On the other hand, carbon steel, which has a melting point of about 1,425 to 1,505°C (2,597 to 2,741°F), may lose its shape or start to oxidize faster in such heat, yet it stands the same amount of stress directly better than steel does.

Ductility and Rust: Myths That Need to Be Clarified

The selection of materials for different applications often involves confusion due to the misconceptions about metal ductility and rust susceptibility. One of the major myths is that copper, aluminum, and other ductile metals are always rusty-free or rustless. But it is important to make clear that “rust” applies only to the oxidation of iron and its alloys (such as steel) and that, while metals like copper or aluminum do not rust, they can corrode under certain conditions, such as exposure to saltwater or acidic environments.

The other common misunderstanding is about stainless steel. Although its chromium content gives it enhanced resistance to rust, it is not totally immune to corrosion. Studies indicate that the 304 grade of stainless steel is quite resistant to general rust but may not be able to cope with the very specific conditions of high chloride levels, as in marine environments. In case of higher resistance to pitting and crevice corrosion, grade 316, which has molybdenum, is the one to go for. Studies indicate that the corrosion resistance of 316 stainless steel is approximately 20% greater than that of 304 in saltwater.

Reference Sources

-

Hydraflu

- Title: Stainless Steel Melting Point: Key Considerations for …

- URL: https://www.hydraflu.com/stainless-steel-melting-point/

- This source discusses the melting point of stainless steel and its variations based on different types of steel.

-

Hy-Proto

- Title: Stainless Steel Melting Point: Essential Guide for B2B

- URL: https://hy-proto.com/stainless-steel-melting-point-essential-guide-for-b2b

- This guide provides insights into the melting points of various stainless steel types, focusing on B2B applications.

-

SteelPro Group

- Title: Stainless Steel Melting Point: Measurement, Influencing …

- URL: https://steelprogroup.com/stainless-steel/properties/melting-point/

- This source offers technical details about the melting points of precipitation hardening stainless steel and other types.

Frequently Asked Questions (FAQs)

❓ What is the melting point of stainless steel?

Stainless steel is usually melted at the temperature range of 1400 °C to 1450 °C (2552 °F to 2642 °F) approximately. The exact melting point depends on the specific alloy and its chemical and physical properties, including the proportion of chromium and nickel.

❓ How does the melting point of stainless steel compare to carbon steel?

Steel’s melting point is generally lower than that of stainless steel. Carbon steel, for instance, has a melting point of around 1425 °C to 1540 °C (2600 °F to 2800 °F) varying with carbon content, whereas the melting point of stainless steel always lies in the high temperature range because of the addition of alloying elements.

❓ What factors affect the melting point of stainless steel?

The melting point of stainless steel can vary due to its grade, specific alloying additions, and overall chemical composition. For example, high carbon stainless steel will have a different melting temperature compared to the low carbon grades.

❓ What are stainless steel alloys and their melting points?

Stainless steel alloys are different types of stainless steel with the addition of different alloying elements that give the required properties like corrosion resistance and hardness. Each alloy can have a specific melting point; for example, austenitic stainless steel usually has a melting point of approximately 1400 °C, whereas martensitic types may vary slightly.

❓ What is the significance of the solidus and liquidus in stainless steel?

The solidus and liquidus lines represent the temperature intervals during which a metal changes from solid to liquid. In case of stainless steel, the liquidus is the stage at which it is fully melted, while the solidus is the temperature under which the alloy remains completely solid. Recognizing these temperatures is very important for processes like welding and casting.

❓ How does the melting point of stainless steel relate to service temperatures?

The melting point of stainless steel is very much higher than the usual service temperatures, which are typically from 300 °C to 600 °C (572 °F to 1112 °F) for various applications. This very high melting point enables stainless steel to retain its integrity and strength even at high temperatures.