Cutting stainless steel is one of the most essential tasks in many DIY and professional projects, yet an angle grinder isn’t always the most practical or accessible option. Whether you’re concerned about safety, don’t have the right tools, or just want a cleaner and more precise method, it can still be quite challenging to find alternative ways to cut this durable material. This article presents the use of the most effective and reliable techniques to cut stainless steel without a grinder, thus, allowing you to achieve precision and efficiency while maintaining a safe approach. You will be given everything from handy tips to time-tested methods to discover the best solutions for your cutting needs. Stay tuned to find out the tools and strategies that will help in the simplification of your stainless steel cutting projects.

Different grades of Stainless Steel

Austenitic Stainless Steel

Austenitic stainless steel is the most popular form comprising around 70% of the total world production. It has very high concentrations of chromium (16-26%) and nickel (6-22%), which both contribute to a very high degree of corrosion resistance and ductility. The grades 304 and 316 are the prominent examples. The austenitic steel is non-magnetic and it is extensively applied for kitchen utensils, medical tools, and chemical storage tanks.

Ferritic Stainless Steel

Ferritic stainless steel has inferior corrosion resistance to austenitic stainless steel because of lower chromium content (11-17%) and no nickel. Advantages of ferritic stainless steel include higher thermal conductivity and being magnetic. Common grades such as 430 and 409 find application in the production of automotive exhaust systems wherein the requirement of corrosion resistance is high and architectural decorations. It is not as ductile as austenitic which is why ferritic steel is suitable for simple forming operations only.

Martensitic Stainless Steel

Martenisitic stainless steel consists of a moderate proportion of chromium (12-18%) and a minuscule amount of nickel. It is mainly characterized by hardness and strength which are obtained through the application of heat treatment. The grades 410 and 420 find application in the manufacturing of cutlery, surgical instruments, and turbine blades. However, the grade is not as corrosion resistant as the austenitic and ferritic types.

Main Uses of Stainless Steel

1. Construction and Architecture

Stainless steel has gained general acceptance and is now the default material in contemporary practices due to its many advantages. One example is that the Chrysler Building’s spire and Burj Khalifa’s facade are made of stainless steel. The construction sector accounts for approximately 26% of the world’s total stainless steel demand, where it is majorly used for cladding, roofing, handrails, and structural supports.

2. Automotive Industry

Stainless steel is mostly used in the automotive industry as it has both rust-proof and high-temperature resistant properties. The most common applications are in the production of exhaust systems, trimming, and supporting parts. The recent data indicates that 12% of stainless steel demand comes from the auto industry, with electric vehicles further electrifying this demand.

3. Food and Beverage Industry

Hygiene standards are very high in the food and beverage processing industry, and stainless steel is the most important material in this regard. Non-reactivity and ease of cleaning are the key properties that make stainless steel so suitable for equipment such as that for food preparation, storage and piping. For example, food-grade stainless steel (usually 304 and 316 grades) is less corrosive and thus, is able to comply with safety standards while at the same time prolonging the life span of equipment that gets exposed to acids, salts or moisture.

4. Medical Equipment

Stainless steel plays an essential role in the healthcare applications such as surgical tools, implants, and hospital equipment. Its biocompatibility and resistance to corrosion convince the user that both the patient’s safety and the tool’s functionality duration might last longer. The 316L alloy is the most sought after for orthopedic and dental implants, and it is reported that surgical-grade stainless steel constitutes a large percent of the total material used in medical centers worldwide.

Comparison of Cutting Methods for Stainless Steel

Laser Cutting

Laser cutting is one of the cutting-edge and most accurate methods of cutting stainless steel, which takes raw metal and uses laser beams to produce stylish and precise cuts. This technic is mostly suitable for small order production, tight tolerances, and high-quality finishes, becoming the choice of preference in sectors like aerospace, automotive, and medical device manufacturing.

The global laser cutting machine market is expected to be worth $6.6 billion by 2027, with a compound annual growth rate (CAGR) of 9.1% during the 2022-2027 period, according to recent figures. Some of the laser cutting perks are nearly zero waste, thermal distortion minimization, and the capability to slice through the whole spectrum of stainless steel thicknesses from as thin as 0.2 mm to super-thick plates of more than 25mm, based on the laser technology selected.

In addition, the development of fiber laser systems has not only increased but also improved the cutting speeds and energy efficiency. For instance, fiber lasers can triple the speed of cutting compared to conventional CO2 lasers when treating thin stainless steel sheets. Pairing this technology with CNC (computer numerical control) allows the manufacturer to have unmatched precision and repeatability; therefore, less time and money are spent on production.

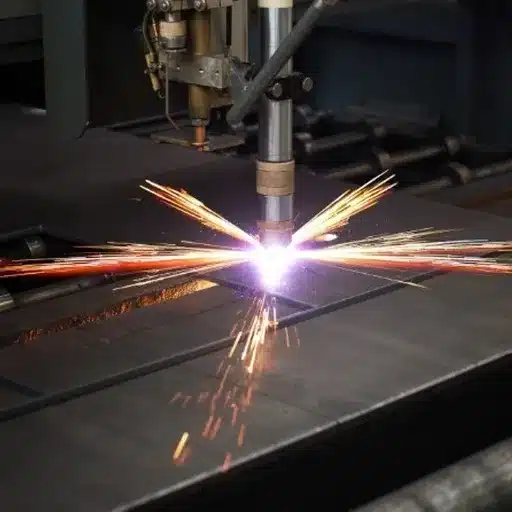

Plasma Cutting

Plasma cutting is among the fastest and most flexible ways to cut electric conductive materials, including stainless steel, aluminum, and carbon steel. By means of the process, which utilizes the accelerated hot plasma jet to penetrate the metal, one gets the idea of how plasma cutting can be recognized for its efficiency and accuracy when dealing with the whole range of thicknesses from thin sheets to heavy plates.

The current plasma cutting technology has come a long way and gained so much. The combination of the CNC technique with the plasma cutter can accelerate the cuts to 200 inches per minute, depending on the type and thickness of the material. Thus, for the thickness range of the materials, the process can compete with other methods on the basis of speed. Certain industries report that plasma cutting has a speed advantage of up to five times over traditional oxy-fuel cutting in specific cases.

Moreover, the price of plasma cutting still remains its biggest advantage, covered by the fact that it is particularly economical when cutting thicknesses up to one inch. However, if thicker metals are to be cut, a high-definition plasma capable system can not only improve the edge quality but also lessen the amount of secondary finishing required. In addition, the mark of progress in plasma torch designs has brought down the cost of consumables and prolonged the life span of cutting parts, thus enhancing economic gains further.

Waterjet Cutting

The process uses high-pressure water jets (usually visible as a thin, fast stream) that move quickly forward; sometimes, even abrasive particles are added to the jet where faster cuts are needed. The technology is praised for its ability to cut metal, stone, glass, composites, and even soft materials like foam or rubber at no heat, thus it is the preferred process in applications where heat-affected zones may damage the integrity of the material.

The extreme precision of waterjet cutting can be pinpointed as one of the major benefits since it can reach tolerances of ±0.003 inches. This degree of precision turns out to be perfect for the aerospace, automotive, and manufacturing industries, where even the smallest and most intricate designs are demanded. Non-thermal cutting gives an additional advantage of the lack of warping or alteration of the properties of the material, which is the main problem in thermal cutting.

Waterjet cutting is also happening in a way that is friendly to the environment. No harmful smoke or heat will be emitted and the reusable water and abrasive can be used again in the cutting process. Currently, the industry claims that newly developed waterjet system can run at up to 90,000 psi making them capable of cutting through ten inches or more thick materials. This feature of versatile and powerful along with the cutting process makes waterjet cutting the most cutting-edge technology of all.

Pros and Cons of Each Cutting Method

Efficiency and Speed

Efficiency and speed are the main factors that help to determine the specific applications for cutting methods. Mechanical sawing is a great example of a cutting technique that has advantages in precision and versatility, especially in low-volume operations. The machine can cut materials such as metals, plastics and composites with a high precision through the use of advanced technology and automation. A modern mechanical saw can cut at a speed of 1,400 surface feet per minute (SFM) or even higher depending on factors like material and blade type. As a result, the process becomes cost-effective for small and medium production.

However, laser cutting technology confidently outshines the traditional sawing methods in terms of speed, especially when the output is large volume. A single laser cutting machine can work at a peak speed of 20,000 millimeters per minute when cutting through thin sheets of steel, thereby catering to the needs of sectors like the automotive and aerospace industries. Nonetheless, laser cutting still remains less efficient than the traditional method when it comes to working the harder metals, as longer exposure leads to slower progress and hence less cutting in that given time.

Cost-Effectiveness

Cost-effectiveness is one of the main factors to be taken into account when comparing the various cutting methods and it is especially important for those industries that are trying to maximize their output while keeping down their expenses. Waterjet cutting, although being extremely accurate, is generally more costly than laser or plasma cutting and that is because of its higher operating costs. As per the industry data, the operating cost for waterjet cutting varies from $20 to $40 per hour, which is based on factors such as abrasive consumption, nozzle lifespan, and pump maintenance. The method is most fit for those projects that need very accurate cutting or complex materials to be cut and this justifies the cost.

On the contrary, laser cutting is a more economical method for thinner materials with operating cost averaging around $10 to $20 per hour. Its being efficient with metals such as stainless steel and aluminum and being cost-effective has made it even more popular among small to medium production runs. New fiber laser machines are getting faster and have their maintenance costs further lowered, thus making them even more economical for high-volume production as a result of the recent progress.

Essential Safety Tips for Cutting Stainless Steel

Above all, it is necessary to wear the right personal protective equipment when cutting stainless steel, such as hard hats, gloves, and safety spectacles at least. I also have the area of work properly ventilated, so the smoke can be avoided, and I check the equipment to be sure it is perfectly working before starting.

Personal Protective Equipment (PPE)

Eye Protection

Safety goggles or shields are a must to protect against highly bright plasma or laser light burning the eyes, and also against the sparks and flying particles coming from the cutter. According to OSHA, about 36,000 such injuries occur every year in the U. S., which makes the need for proper eyewear even more evident.

Gloves

Welding gloves made of leather with double stitching give both heat resistance and durability, and besides, they are the main source of protection for hands from hot metal and its sharp edges. Heat-resistant gloves are what hands need to be protected from both temperature and cut metal edges.

Respiratory Protection

The cutting process of stainless steel produces smoke and gases such as hexavalent chromium which is a very potent carcinogen among other lung-related diseases. Hence, a respirator that is NIOSH certified will significantly lower one’s exposure to inhalation and thus, prevent the occurrence of respiratory problems due to long-term exposure.

Safe Handling Techniques

Ergonomic Lifting

Promote the right lifting methods, like bending the knees, keeping the back straight, close the load to the body. Always use mechanical help in the case of heavy items, such as a fork-lift, dolly, or hoist.

Weight Limits

Set a weight limit of 50 pounds for manual lifting of materials per person and in general. For regularly lifting, coordinate according to the NIOSH (National Institute for Occupational Safety and Health) lifting equation to avoid the risk of strains.

Use of Gripping Aids

Always put on gloves or use grip-enhancing tools when dealing with small, awkward, or possibly slippery items. Proper gripping means more control and therefore lesser chances of drops occurring accidentally.

Teamwork for Heavy Loads

For big or oddly-shaped items, make use of team-lifting approaches. Beforehand, talk and decide how to share the load among the workers in order to achieve their coordinated movements.

Reference Sources

-

TopsBest Precision Blog

- Title: How To Cut Stainless Steel: 12 Best Ways

- Summary: This blog outlines various methods for cutting stainless steel, including tools like abrasive cut-off saws, oxy-acetylene, circular saws, and more. It provides practical insights into the tools and techniques suitable for different applications.

-

VMT CNC Blog

- Title: 10 Ways To Cut Stainless Steel Sheet

- Summary: This article discusses ten effective methods for cutting stainless steel sheets, such as using hacksaws, band saws, miter saws, and plasma cutters. It also highlights the pros and cons of each method.

-

KDM Fabrication Guide

- Title: Stainless Steel Cutting 101: A Practical Guide

- Summary: This guide provides a comprehensive overview of cutting stainless steel, focusing on tools like miter saws with fine-tooth carbide blades. It emphasizes safety and precision in the cutting process.

Frequently Asked Questions (FAQs)

What is the best method for cutting stainless steel?

The method for cutting stainless steel depends on the thickness and kind of material used. Thinner stainless steel sheets need a circular saw with a metal cutting blade or a rotary tool to get a clean cut, while thicker stainless steel plates necessitate the use of a band saw or abrasive cutting methods that are more effective. One must always select the correct blade for cutting to get the right fit and also the quality of the cut.

How to select a cutting tool for stainless steel properly?

Selecting a cutting tool for stainless steel entails assessing the thickness of the material and the quality of the cut that one wishes to achieve. A band saw or a circular saw along with a proper cutting disc can be used for thick stainless steel. On the other hand, thin materials can be cut with a rotary tool or an angle grinder equipped with a metal cutting blade work well. Metal cutting tools designed for this purpose should always be used to get the best results.

Is an angle grinder suitable for cutting stainless steel?

An angle grinder can be used for cutting stainless steel if the appropriate cutting disc is selected. A metal-cutting abrasive disc will provide a clean cut. It is important for the operator to have a steady hand and to allow the blade to do the work so as to avoid overheating the workpiece.

Which methods are preferable while working with thin stainless steel?

Utilizing a circular saw or a noisy tool with a fine-toothed blade are the methods for cutting thin stainless steel. It is necessary to carefully follow the cut line and to use cutting fluid or oil in order to decrease friction and prevent shrinking. This will make the cutting process consistent and the edge of the cut will be of good quality.

What methods should I use to cut stainless steel plates and retain their edges?

When cutting stainless steel plates, it is very important to use the appropriate cutting blade, whether it is a saw blade, cutting wheel, or an abrasive disc, in order to obtain a clean cut. Moreover, the sharpness of the blade should be metal-cutting and the fluid to be applied during the cutting process should also be for that purpose.

Conclusion

This comprehensive guide has explored various methods and techniques for cutting stainless steel without an angle grinder. From understanding different grades of stainless steel to mastering advanced cutting technologies like laser, plasma, and waterjet cutting, you now have the knowledge to choose the right approach for your specific project. Remember to prioritize safety by using appropriate personal protective equipment and following proper handling techniques. Whether you’re working on a DIY project or professional application, these methods will help you achieve precise, clean cuts while maintaining efficiency and safety standards.