The process of cutting stainless steel sheets might come across as a rather difficult one due to their toughness and resistance to abrasion. Nevertheless, if one possesses the appropriate tools, methods, and supervision, this operation can be made easy not only for professional projects but also for DIY endeavors. The present guide will not only simplify the whole process by providing unambiguous and workable steps but also assist you in achieving neat and accurate cuts with little effort. If you are an experienced metalworker or simply a beginner with your first project, this article will provide you with the know-how and the self-assurance to treat stainless steel sheets as if you were an expert. Continue reading to learn all that you need to know before cutting for the first time!

Introduction to Cutting Stainless Steel

Proper Techniques and Their Importance

The entire cutting process of stainless steel hinges on the application of right and very specific techniques, which, in turn, lead to precision, safety, and efficiency. If methods are improper, they might result in an unintentional waste of materials, rough edges, damage to the tools, or even injuries to workers. Cutting stainless steel, which is known for its toughness and resistance to rust, is a more difficult process than cutting aluminum and similar other metals. Thus, it is really important to use tools and strategies that are tailor-made for that specific operation.

A 2023 metalworking tools study within the industry found that more than 60% of material errors in stainless steel projects are traced back to either inadequate cutting methods or the use of wrong tools. For example, without cooling or lubrication, very high heat generated as a result of cutting could cause the steel to warp or change in color. The use of plasma cutting, laser cutting, or carbide-tipped blades has been acquitted by the test of time as cleaner and more accurate cutting, minimizing the wear and tear on the machines, and thus the operational delays are reduced.

Characteristics and Types of Stainless Steel Sheets

Stainless steel sheets are one of the most flexible and long-lasting materials in use today, fit for almost every industry sector, like construction, automotive, aerospace, and consumer goods. Taking into account their resistance to corrosion, strength, and beauty, the stainless steel sheets are produced from a mixture of iron, chromium, and other alloying elements. Among all, the one that is most notable is the chromium content, which is usually not less than 10.5%, as it develops a protective layer of chrome oxide on the surface of the stainless, which prevents it from getting rusted and corroded.

Stainless steel sheets come in a wide range of grades and finishes reflecting different applications. For example, the 304 stainless steel grade is the most common one for kitchen and architectural use because of its outstanding corrosion resistance and weldability. The opposite side is 316 stainless steel with molybdenum which is very resistant to chlorides and is intended for marine and chemical applications. Thicknesses are usually from 0.4 mm to several millimeters, covering both structural and decorative needs.

Tool Selection for Cutting Stainless Steel

Best Tools for Cutting Stainless Steel Sheets

Plasma Cutters

Plasma cutters are the best option when it comes to cutting stainless steel sheets of different thicknesses. The secret weapon for them is the ability to ionise the gas, which allows them to melt the steel and create a plasma stream, thus achieving clean and smooth edges. New plasma cutting machines are capable of handling 1.5-inch thick stainless steel and are thus the fastest and most accurate machine in the manufacturing process.

Angle Grinders

Though best used with thinner stainless steel sheets, angle grinders are still very versatile and easy-to-use. High-quality cutting wheels can still produce clean edges, though a little polishing afterwards may be needed to improve the finish. Due to their portability and low price, angle grinders are perfect for outdoor jobs.

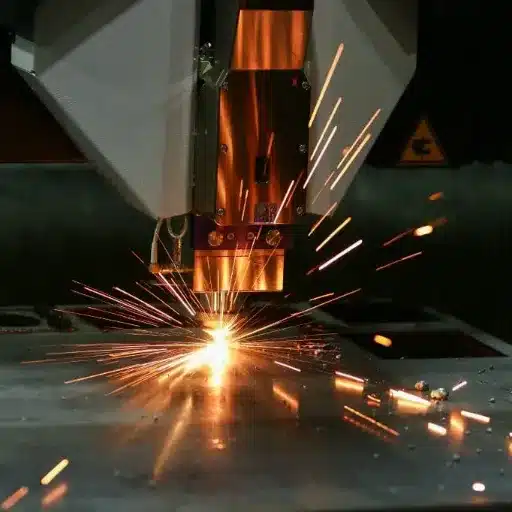

Laser Cutters

Laser cutting has evolved into the favorite technique for working with stainless steel sheets thanks to its sharpness and quickness. CO2 and fiber laser systems are able to slice through stainless steel of 0.25 inches thickness with great precision. This procedure is getting more popular in sectors that need detailed work, like aerospace and automotive production. Reports indicate that laser cutting can attain tolerances of ±0.005 inches.

Circular Saws with Carbide Blades

Circular saws with carbide-tipped blades are recommended for reliable cutting of sheets with a thickness of up to 0.5 inches. They can cut at high speeds without the need for cooling, which leads to clean cuts and minimizes the possibility of the material getting warped during the cutting process. Some modern circular saws even feature a speed control option to match cutting conditions with the material type.

Using an Angle Grinder Effectively

Choose the Right Disc

The type of disc used is critical to achieving the desired outcome. For stainless steel, a thin cutting wheel (typically 1.0-1.6mm thickness) is recommended as it provides precision and reduces heat generation, which can discolor the metal. For grinding purposes, a flap disc with zirconium grains is ideal.

Set the Correct Speed

Modern angle grinders offer adjustable speed settings. For cutting stainless steel, maintaining a speed of around 8,000–12,000 RPM is generally suitable. Consistently high speeds promote smoother cuts and prevent jamming.

Use Protective Gear

An angle grinder generates sparks and debris, necessitating the use of proper personal protective equipment (PPE). Wear safety goggles, gloves, a long-sleeved shirt, and a face shield to protect yourself from potential hazards.

Avoid Overheating

Stainless steel is prone to heat discoloration during cutting. To minimize this, make short, shallow passes instead of continuous deep cuts. Additionally, allowing the steel and the grinder to cool intermittently can reduce heat buildup.

Safety Precautions When Cutting Stainless Steel

Essential Safety Gear

Safety Glasses or Goggles

Eye protection from the flying metal bits is a must. Safety spectacles with side shields or goggles meeting ANSI Z87.1 requirements are very good at stopping eye injuries.

Hearing Protection

Over time, the very loud noise generated by most cutting tools, such as grinders and jigsaws, would lead to gradual loss of hearing. Protect your ears by using earmuffs or earplugs with an NRR of at least 25 decibels.

Cut-Resistant Gloves

Gloves made of materials like Kevlar or other cut-resistant fibers will protect wearers from sharp edges and hot surfaces through the cutting process.

Respiratory Protection

Cutting of stainless steel can release fine metal dust and fumes. A respirator that filters out particles, like N95 or higher, will ensure that no harmful particles are inhaled. In poorly ventilated areas, full-face respirators may be required.

Protective Clothing

Skills with long-sleeved shirts, pants, and aprons made from fire-resistant materials can protect your skin from sparks, heat, and metal pieces.

Safe Handling of Tools

Tool Maintenance

Keeping tools in good condition is very important to get the most out of them and to minimize accidents. For instance, with the cutting tools there will be more user fatigue and also the chances of accidents will increase if the blades are dull. Research shows that regularly cleaned and sharpened tools can boost working efficiency by as much as 20%. Check the tools for fraying and damage before each use in order to prevent unexpected breakdowns.

Ergonomic Practices

Choosing tools that have been ergonomically designed can have a big impact on reducing the physical strain. Tools that are padded, made of lightweight materials, and balanced will give less repetitive stress and injuries. A study has found the risk of musculoskeletal disorders can be reduced by about 30% when using ergonomically designed tools.

Personal Protective Equipment (PPE)

The most recent guidelines mention the very necessity of different PPEs like gloves, goggles, and dust masks that are appropriate for the specific task as a minimum requirement in the workplace. For example, when working with power tools, wearing goggles can reduce eye injuries caused by flying debris effectively by up to 90%.

Proper Training

The risk is very much reduced when the users get professional and user-specific training. Research has shown that companies with professional training programs have 25% less incident rates than those without.

Step-by-Step Cutting Process for Stainless Steel Sheets

Preparing the Workspace

The initial step in the process of cutting stainless steel sheets is to set up the workspace in a manner that is neat, organized, and controlled. A thorough clean-up and an open space can greatly lower the chance of accidents occurring and at the same time, the flow of work will be faster. Following the advice of the industry, you should allocate a big area which is properly lit in order to make the visibility sharper while handling the very sharp tools and the stainless-steel materials. It is good practice to have a sturdy workbench or cutting table that has a non-slip surface so that the sheets do not move around during cutting.

It has been shown by research that injuries at the workplace connected with cutting operations can be reduced by as much as 22% if proper organization and preparation are followed. However, make sure that all necessary tools like cutting shears, grinders, or laser cutters, etc. are present and in the best possible state. Furthermore, it is also important to have personal protective equipment (PPE) which includes safety goggles, gloves, and steel-toed boots, etc. right next to you. The use of suitable PPE according to OSHA standards decreases the chances of injuries significantly.

Measuring and Marking the Stainless Steel Sheet

The measurement and marking need to be very precise if the cutting of the stainless steel sheets is to be done accurately and waste of material minimized. You can start by using a measuring tape of high quality or a digital caliper for getting the most precise measurements. The thickness for the stainless steel sheets is often available in the standard ranges of 0.024 inches (24 gauge) to 0.25 inches (¼ inch). Therefore, it is important that you measure the thickness very carefully so that you can get the right cutting tools and methods.

When marking your cut lines, scratch awl or carbide-tipped marker is recommended because they engrave visible lines on stainless steel surfaces. Regular markers or pens should not be used because their marks can be wiped off or smeared during cutting. Steel straightedge or ruler can help you to stay accurate, along with second checking all measurement before marking. Being precise is very important, therefore, measuring twice and cutting once would be a practical way of avoiding errors.

Executing the Cut with an Angle Grinder

When being precise and careful, an angle grinder cutting of stainless steel is a very powerful technique. First of all, make safety the priority and wear the appropriate protective gear such as safety goggles, gloves, ear protection, and a respirator, thus, protecting yourself from sparks, metal pieces, and noise. It is very important to have a strong workbench or clamping system to hold the stainless steel securely and to avoid cutting through vibrations.

For the purpose of getting clean and accurate cuts, the right cutting disc for stainless steel is to be chosen. It is generally advised to use the thin cut-off wheels specifically designed for metal as they not only generate the least heat but also cause the least curling of the plastic. Thickness between 1mm to 1.6mm is most ideal for stainless steel disc since it offers both precision and effortless cutting.

Troubleshooting Common Issues

Dealing with Uneven Cuts

Check Blade Alignment

It is possible for misaligned blades to create a situation where the cutting tool is not vuied properly and hence the edges will be uneven as a result. Checking and adjusting the blade of your cutting tool regularly will make sure that the blade is aligned properly. If you use a laser guide or mark a cutting track it will aid you in achieving more accurate results.

Optimize Cutting Speed and Feed Rate

Choosing the wrong cutting speed or the wrong way of feeding the material through the cutter will negatively affect the cut in quality. To illustrate, if the cutting speed is high, the risk of heating to the point of distortion of the material may increase along the edges. The general advice is that the speed should be tailored to the material type; for instance, when working with stainless steel one should use slower speeds as compared with soft metals like aluminum. The recent guidelines suggest that the feed rate of 300-400 mm/min is good for most thin sheets, while the thicker ones may need slower rates in order to maintain the quality of the edge.

Evaluate Blade Type and Condition

Confirm that a right type of blade is being used for the material in question. For example, a carbide-tipped blade is recommended for hard metals while a bi-metal blade is a good choice for soft materials. Moreover, dull or worn blades tend to cause the cuts to be uneven. Replace or sharpen blades whenever it’s needed in order to keep up the performance.

Secure the Material Properly

During the cutting process, any movement might lead to the production of jagged or uneven edges. Fix the material with clamps or a vice to make sure that it is positioned absolutely correct. Furthermore, double-check that the workpiece is level and that there are no vibrations when you start the cut.

Addressing Overheating Problems

Inspect Coolant Systems Regularly

Heat dissipation through the use of coolant is a strategy that many cutting systems adopt. Maintain proper coolant levels and that the delivery systems are operational. Also, clean the nozzles that are blocked and change the coolant if it is noticed to be contaminated or degraded. A tool wear reduction of up to 40% due to overheating has been reported by a study published in 2023 by the Journal of Machine Systems when using high-efficiency cooling systems.

Optimize Cutting Speed and Feed Rates

Cutting at excessively high speeds or inappropriate feed rates generates unnecessary friction, leading to overheating. Review the manufacturer’s specifications to find the optimal settings for your machine and material. Research from industrial specialists suggests that reducing cutting speeds by 10% in certain scenarios can drastically lower temperature spikes without sacrificing productivity.

Choose the Right Cutting Tools

Choosing the right cutting tools for the job is critical. For example, carbide or diamond-coated blades are very effective for high-temperature applications since they resist heat. It may be wise to take a plunge and invest in advanced tooling materials which can not only withstand but also perform excellently in more demanding tasks.

Improve Airflow Around the Workspace

Ensure that workspace ventilation is adequate for heat dissipation. For enclosed machines, verify that built-in cooling fans are operational and clean out any dust blocking the airflow. Research by engineering experts demonstrates that machines with proper airflow see a 20% reduction in peak operating temperatures.

Reference Sources

-

Industrial Metal Service

This source offers insights into precision cutting methods for stainless steel sheets, including the use of circular saws and other tools. It emphasizes the importance of using the right equipment for achieving clean and accurate cuts.

Read more here -

Senyo Rapid

This guide is tailored for professionals and manufacturing plants, detailing tools like plasma cutters for cutting through thick stainless steel sheets. It provides practical advice for industrial applications.

Read more here -

Apollo Technical

This source explains various methods for cutting stainless steel sheets, such as using circular saws with carbide-tipped blades. It is a comprehensive guide for both professionals and DIY enthusiasts.

Read more here

Frequently Asked Questions (FAQs)

Can I use an angle grinder to cut stainless steel?

An angle grinder is a valid choice if one intends to cut stainless steel and the thicker the sheet is, the better. Using an angle grinder, one has to be very careful to in the first place pick a cutting disc that is meant for metal and secondly be very gentle with the hand so as not to create unconformity.

What is the process of cutting stainless steel sheet metal in a straight line?

Jigsaw or bandsaw can be used for cutting straight lines on stainless steel sheet metal as these two tools can provide precision. For manual cutting, using a straight edge can be a good to do cutting with a grinder or metal shears. Marking the cutting line definitely with bright color helps to get a straight and clean cut.

What tools would be the best ones for the cutting of stainless steel plates?

The tools that are best suited for cutting stainless steel plates are angle grinders, jigsaws with metal blades, and bandsaws. CNC machines also can be used for fabrication purposes when utmost precision is required. Different tools are dependent on the thickness and type of stainless steel being cut.

Are there ways to cut stainless steel so that the edges are not sharp?

It is indeed possible not to have sharp edges after cutting the stainless steel if proper cutting techniques and the right tools are used. In case of cutting, finishing methods like grinding or sanding edges can help to eliminate the sharpness and make the edge safer. It’s always advisable to use protective gear while cutting to prevent cutting injuries from the sharp edges.

What are the most suitable blades for cutting stainless steel rods?

The most suitable blades for cutting stainless steel rods are the ones that metal cutting blades produced particularly for high-strength materials. A bi-metal saw blade or a carbide-tipped blade can do good in terms of cutting stainless steel rods as they are durable and precise, thus ensuring clean cuts and no excessive wear on the blade.