Known for its multifunctionality, strength, and affordability, China’s 304L stainless steel coil has become a notable part of numerous industries. What makes it particularly distinctive? If you reside in the construction, manufacturing, or automotive industry, knowing the features and uses of this material will give you a competitive advantage. This guide seeks to explain all there is to know about China’s 304L stainless steel coil, including its defining features and benefits, and comparing it with other materials. After reading this article, you will have incisive information to help you evaluate whether this advanced material caters to your requirements.

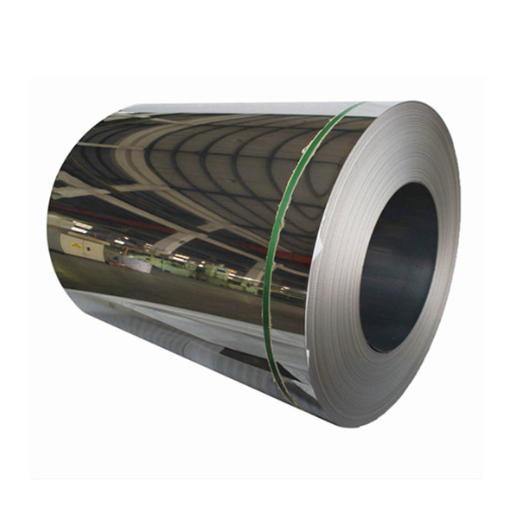

What is a Stainless Steel Coil?

A stainless steel coil is a long strip of stainless steel sheet wound into a coil for easy movement, storage, and further processing. Known for its unmatched strength, relatively low corrosion potential, and dynamic nature, this material is used in construction, manufacturing, automotive, and many other industries. Furthermore, stainless steel coils can be sawed, molded, and manufactured into any shape according to the customer’s precise wants, thus enhancing efficiency in production.

Key Characteristics of 304L Stainless Steel Coil

- Corrosion Resistance

304L stainless steel coil contains heightened properties against corrosive elements, especially in conditions with moisture, acidic chemicals, or chlorides. Furthermore, its low carbon content improves its operational performance, mitigating corrosive damage from welding and high temperatures.

- Low Carbon Content

The 304L “L” designation represents “low carbon,” meaning its carbon content does not exceed 0.03%. This trait also aids in minimizing carbide precipitation scope during welding, sustaining the required corrosion-resistant properties within the heat-affected zone.

- Excellent Weldability

Standard fusion welds may be performed on the 304L stainless steel grade without requiring subsequent welding relief annealing for fatigue reduction, making these joint configurations ideal for almost all applications. They are structurally safe and robust, enduring harsh functional demands.

- High Ductility and Formability

Good ductility and formability allow the material to be easily shaped and fabricated to fit complicated design geometries, giving it a competitive edge in the automotive, construction, and medical industries.

- Good Tensile Strength

With a tensile strength of roughly 70,000 psi (approximately 485 MPa), 304L stainless steel coil demonstrates considerable strength for industrial use.

- Temperature Resistance

It demonstrates reliable operational performance from -196 °C (-321°F) to 870°C (1600°F), useful for cryogenic and high-temperature applications.

- Non-Magnetic Characteristics

In its annealed state, 304L stainless steel is mostly non-magnetic, which is advantageous for sensitive operations requiring low or no magnetic interference.

- Industry-wise Applications

- Construction: Ideal for architectural structures, cladding, and roofing because of its beauty and resistance to corrosion.

- Automotive: Applied in exhaust systems, fuel tanks, and trim parts.

- Food and Beverage: Maintains required sanitation standards, making it fit in food processing machinery.

- Pharmaceuticals and Medical Devices: Maintains required sterility and is resistant to harsh cleaning chemicals.

The 304L stainless steel coil is a genuinely remarkable alloy. It combines durability and versatility with dependable chemical properties that modern industries and commerce continuously seek to develop and innovatively apply.

Differences Between 304 and 304L Stainless Steel

| Parameter | 304 Stainless Steel | 304L Stainless Steel |

|---|---|---|

| Carbon Content | Max 0.08% | Max 0.03% |

| Corrosion Resistance | Good | Better in welded conditions |

| Weldability | Requires post-weld annealing | No post-weld annealing needed |

| Tensile Strength | Higher (≥525 MPa) | Lower (≥485 MPa) |

| Applications | General use, food industry, architecture | Chemical, marine, and medical equipment |

| Cost | Lower | Slightly higher |

| Magnetism | Non-magnetic | Non-magnetic |

| Heat Resistance | Up to 800°C | Up to 800°C |

Common Applications of Stainless Steel Coil

Stainless steel coils’ exceptional strength, durability, and resistance to corrosion make them a popular choice among various industries. Here are five common uses of Stainless Steel Coils.

- Automotive Industry

Stainless steel coils are also used to manufacture mufflers, exhaust systems, and various structural panels. They are popular in the automotive industry because they can endure extreme temperatures and corrosive conditions, offering safety and long life.

- Construction and Architecture

Stainless steel coils are frequently used for roofing, building facades, and other structural components. They provide a sleek and modern appearance and withstand weathering. They are also very light and strong, which makes them ideal for architectural designs.

- Food Processing Equipment

Food-grade stainless steel coils manufacture kitchen appliances, storage tanks, and conveyors because they ensure safety and hygiene and mitigate the chance of contamination through easy cleaning and maintenance.

- Medical and Pharmaceutical Equipment

Surgical instruments, sterilization trays, and other medical devices are made of stainless steel coils because they are non-reactive and remain sterile. They can also endure harsh cleaning and sterilization procedures, making them even more helpful.

- Energy and Power Generation

Stainless steel coils are critical in producing boilers, heat exchangers, and power plant turbines. Their capacity to operate under challenging high pressure and high temperature conditions makes them suitable for strict application requirements.

How is 304L Stainless Steel Coil Manufactured?

- Melting and Casting

An electric arc furnace melts the raw materials: iron, chromium, nickel, and molybdenum. The liquid metal is then cast into slabs for additional treatment.

- Hot Rolling

The slabs are heated and rolled to reduce thickness and attain the final required shape. This procedure additionally improves the material’s strength and workability.

- Annealing

The rolled material undergoes annealing to improve ductility and relieve internal stresses. During annealing, the steel is heated and then cooled under specific conditions.

- Pickling

During pickling, the surfaces of the annealed coils are treated with an acid solution that removes scale and oxidized layers, which are classified as surface impurities.

- Cold Rolling (Optional)

For some applications, the coil needs to be more precisely shaped and have a smoother finish, so it undergoes cold rolling, improving surfaces, tolerance, and precision.

- Final Inspection and Quality Control

The completed coils are inspected for conformance to the set standards and customer requirements, including the surface finish, dimensions, and other mechanical properties.

The Cold Rolled Process Explained

The cold rolled process increases steel’s strength, hardness, and surface finish while achieving tight tolerances by compressing the steel at room temperature.

Role of Annealing in Production

I count on the annealing process to achieve the necessary mechanical properties in the material while also making it more straightforward to work with in later manufacturing stages. This process enhances the material’s machinability by relieving internal stresses and improving ductility.

Understanding the Steel Plate and Stainless Steel Sheet Production

Fabricating steel plates and stainless steel sheets involves several processes that require great care to maintain the desired quality, strength, and utility for diverse applications. Here are five essential processes involved in production:

- Selection of Raw Materials

The quality of the iron ore and its alloying ingredients, including chromium, nickel, and molybdenum, is carefully checked to ensure the desired chemical composition.

- Melting and Refining

The raw materials are melted in Basic Oxygen Furnaces or Electric Arc Furnaces, where their impurities are refined, and elements are added to enhance the material’s specific properties.

- Casting

The refined steel is poured into molds or cast into primary forms such as slabs, blooms, or billets from which other final shapes can be made using further processing.

- Hot Rolling

The cast steel is heated and re-rolled at elevated temperatures to produce plates or sheets of the preferred thickness. This stage guarantees that the material is free from internal defects.

- Surface Treatment and Finishing

Steel plates or sheets are subjected to surface finishing operations, where they are annealed, pickled, or polished to improve the surface and increase resistance to corrosion for different industrial uses.

Who are the Leading China Stainless Steel Coil Suppliers?

China is the market leader in stainless steel coils, with its coil suppliers providing reliable services. They are Tisco, Baosteel, Tsingshan, Jisco, and Lisco.

- Tisco is Taiyuan’s major corporation and China’s largest stainless steel producer. It has developed advanced production technology.

- Baosteel is also a strong competitor in the industry and a major global player. They offer stainless steel coils that can be used with other devices.

- Baosteel is the major competitor to Tsingshang, which specializes in cutting-edge innovation.

- Jisco is known for producing products that are friendly to the industrial sector. He provides quality, tailored coils for the market.

- Lisco is a renowned distributor of stainless steel goods, whether at home or abroad. Their reputation is rooted in consistent satisfactory results.

The companies are anchored by strong reputations rooted in innovative manufacturing and servicing both local and international markets.

Top China 304L Stainless Steel Coil Manufacturers

| Manufacturer Name | Key Features | Location |

|---|---|---|

| LISCO | High-quality coils, ISO-certified | Guangdong |

| Tsingshan Holding Group | Global leader, 10M tons annual capacity | Zhejiang |

| JISCO | Diverse products, Top 500 enterprise | Gansu |

| Hongwang Group | Specialized in cold-rolled stainless steel | Guangdong |

| Bao Steel (Baosteel) | Global leader, ISO-certified | Shanghai |

| YONGJIN | Innovative, 320+ patents | Zhejiang |

| Galaxy Metal Product Wuxi | High corrosion resistance, custom solutions | Jiangsu |

| Wuxi Qingfa Tong Metal | Wide product range, competitive pricing | Jiangsu |

| ChengDe Steel | High-tech enterprise, seamless pipe expertise | Hebei |

| Guangdong Hongwang Metal | Colored and functional stainless steel | Guangdong |

Factors to Consider When Choosing Steel Coil Manufacturers and Suppliers

| Factor | Description |

|---|---|

| Product Quality | Ensure coils meet required standards. |

| Certifications | Check for ISO or other industry standards. |

| Production Capacity | Reflects the ability to handle large orders. |

| Customization Options | Availability of tailored specifications. |

| Delivery Time | Speed and reliability of shipping. |

| Pricing | Competitive and transparent cost structure. |

| Reputation | Check reviews and references. |

| Customer Support | Responsiveness to queries and concerns. |

| Technology and Equipment | Use of advanced production methods. |

| Sustainability | Commitment to environmentally friendly practices. |

| Location | Proximity reduces shipping costs. |

| After-Sales Service | Support post-purchase for issues. |

| Payment Terms | Flexibility in payment options offered. |

What are the Benefits of Using 304L Stainless Steel Coil?

- Corrosion Resistance: 304L stainless steel is best for environments with moisture and chemicals because it is exceptionally corrosion resistant.

- Durability: 304L stainless steel can withstand immense amounts of pressure and stress while doing heavy physical work, giving it long-lasting durability.

- Versatility: 304L stainless steel is used in construction, automotive, and manufacturing, making it suitable for many sectors because of its ease of fabrication.

- Low Carbon Content: The steel’s improved overall performance and weldability are achieved by minimizing carbon precipitation during welding, making it more suitable for welds.

- Hygienic Properties: Pure stainless steel prevents bacteria from attacking it and helps keep it clean, making it suitable for surgical implements and food preparation.

Corrosion Resistance and Durability

Stainless steel is one of the most accepted materials in several industries, due to its durability and exceptional corrosion resistance. This resistance occurs due to the passive, protective chromium oxide layer that forms on the surface of the steel, guarding it against rust and environmental damage. The chromium content, usually 10.5% or more by mass, allows this layer to form, maintaining the capability of self-healing upon exposure to oxygen, even with some scratches or damage.

Research indicates that 316 stainless steel is most resistant to harsh marine and chemical environments because of its higher molybdenum content. Industry data also states that 316 stainless steel contains approximately 2-3% molybdenum, enabling it to resist pitting and crevice corrosion substantially better than 304 stainless steel. For instance, 316 stainless steel’s chloride tolerance is up to 1,000 ppm, and for 304 stainless steel, a lower surrounding chloride level is preferred.

Also, progress in stainless steel alloys has bolstered their durability even further. Duplex stainless steels are of particular note because of their austenitic and ferritic grade compositions. They exhibit impressively high tensile and yield strength and remarkable rust resistance. These alloys survive for many decades even under harsh operational conditions, thus reducing maintenance requirements and increasing sustainability in the long run.

Stainless steel inox is used in numerous industries to demonstrate its excellent lifespan. For example, steel constructions in metropolitan and industrial regions typically survive for 50 years at a minimum with very little deterioration. Alongside this lifespan, stainless steel can be recycled, with 90% being recyclable globally, making it environmentally friendly with high regard in the market.

Comparing 304L with Other Stainless Steel Materials

| Parameter | 304L Stainless Steel | 304 Stainless Steel | 316 Stainless Steel |

|---|---|---|---|

| Carbon Content | ≤ 0.03% | ≤ 0.08% | ≤ 0.08% |

| Corrosion Resistance | Better after welding | Good | Excellent in chloride environments |

| Weldability | No post-weld annealing needed | May require post-weld annealing | No post-weld annealing needed |

| Strength | Lower tensile strength | Higher tensile strength | Similar to 304 |

| Applications | Welded structures, chemical equipment | General-purpose, food industry | Marine, chemical, and medical equipment |

| Cost | Slightly higher | Lower | Higher due to molybdenum content |

Cost-Effectiveness and Longevity

Regarding stainless steel and eco-friendly factors, 304L stainless steel is the best option. Its low upkeep makes it appealing, as does its durability and reduced corrosion. The total expense might be pricier than some substitutes when looking at initial costs, but over time, it’ll be shown as the most cost-effective option.

How to Properly Maintain Stainless Steel Coil?

For the maintenance of a stainless steel coil, ensure the following steps are performed:

- Systematic Maintenance: Use warm water and mild soap to scour away gunk and grime. You can use a sponge and a soft cloth so that no scratches are inflicted while cleaning.

- Do Not Use Cleaning Agents: Abrasive or very strong cleaning agents containing chlorine must be avoided because they negatively influence the protective layer surrounding the steel.

- Completely Dry: Remove excess moisture after washing to stop water marks without creating stale air.

- Regular Checks: Regular checkups are done for corrosion signs, war, or damage, and measures are taken to rectify issues immediately to prevent additional disintegration.

- Protective Coating (optional): Additional measures, such as specialized stainless steel protectants, can be added in extreme settings and environments.

Following these steps, you can change a stainless steel coil’s appearance while increasing its life.

Regular Maintenance Tips for Stainless Steel Products

Known for their corrosion resistance, stainless steel products still require regular maintenance to sustain their durability and functionality. Care routines must include regular maintenance cleaning, current science-based practice recommendations, and data. Presented below are best practices.

- Right Cleaning Agents

Recent recommendations emphasize using soap or pH-neutral cleaners to retain the cleanliness of stainless surfaces. However, products containing chlorine bleaches or hydrochloric acids must be avoided as they promote forms of pitting corrosion. Studies suggest proper cleaning extends steel lifespan over 40% compared to improper or no cleaning40%.

- Cleaning Against the Grain

Brushed finishes are particularly susceptible to visible scratching, but modern cleaning techniques emphasize the importance of moving with the grain when wiping stainless steel to improve uniformity and avoid scratches. Furthermore, polished finishes lack scratches, promoting better visual appeal. Research suggests that scratches are particularly noticeable on brushed surfaces and can be left behind with face cleaning.

- Deep Cleaning Scheduling

Outdoor deep maintenance washes utilize specialized stainless steel cleaning solutions, abrasively strip oils and grease-based contaminants every month. This is useful for long-term mitigating corrosion and discoloration. Maintenance experts suggest that systematic deep cleans improve scheduled wear and tear by 30% over not cleaning well-defined scheduled intervals.

- Mental Exposure to Severe Acc environments

Stainless steel used in areas with high humidity, salt water, or intense heat requires constant monitoring. Adding protective coatings, especially polymer-type ones, enhances the corrosion resistance of the protective sleeve. Recent advancements in protectants have greatly improved the resistance, with some coatings lasting up to 24 months before reapplication is needed.

- Inspect and Maintain Wearable Technology regularly

All joints and welds on stainless steel products are usually the most problematic. Try to monitor these periodically for any early signs of stress, seam failure, or rust. These actions, while small, can help limit future repair costs. Insight into mechanical maintenance suggests that critical repairs needed are reduced by 50 percent through proactive inspection.

Stainless steel can withstand rough treatment, but meticulous care according to modern standards will enhance its sheen, safeguard its structural integrity, and prolong its life.

Dealing with Corrosion and Wear

Although wear and corrosion issues may arise with stainless steel, they can be controlled with the proper practices and maintenance. Here are five tips for managing these problems:

- Cleaning Schedule

Believe it or not, regular dusting with a gentle surfactant goes a long way. Arm grease and other types of surface dirt need to be removed. Remember never to use abrasive cleaning pads, as they scratch the surface.

- Coating Protection

Sealants formulated or manufactured for stainless steel can be affected by Moisture and salt, which can easily slide off protective films.

- Electropolishing

Stainless steel becomes smoother and freer of impurities, improving its corrosion resistance. However, this process makes the material more susceptible to damage and intensifies harsh conditions.

- Cross Contamination Prevention

Use only stainless steel maintenance tools. Maintaining those tools ensures that particles from carbon steel do not fall onto the tools, where cross-contamination leads to rust.

- Hygienic Control

Dehumidifiers and controlled storage spaces are helpful in reducing the rate of condensation. Avoiding overly hot and humid areas helps cope with saltwater and more aggressive acidic chemicals.

Follow the detailed strategies outlined in this guide to reduce the impact of corrosion and wear and sustain the efficiency and life cycle of stainless steel products.

Best Practices for Cleaning and Storage

Effective cleaning and storage of stainless steel is crucial in maintaining its durability, aesthetic appeal, and corrosion resistance. Below are best practices for the maintenance of stainless steel products, along with the latest research insights:

- Cleaning Stainless Steel

- Select Non-Abrasive Detergents: Use only non-abrasive, non-pH alkaline, and surface-safe detergents. Harsh chemicals can corrode stainless steel’s protective layer.

- Set a Routine: Set a routine to wipe down stainless steel surfaces at least once weekly to minimize cumbersome dust buildup. For high-touch surfaces, some cleaning at least once a week is advised.

- Avoid Chloric Cleaning Products: Pitting corrosion could be caused by Chloride elements found in high temperatures and chlorides. These components break down stainless steel.

- Shining: When polishing for shine, use microfiber cloths and soft sponges rather than traditional polishing tools to ensure scratch-free shine.

- Thorough Rinsing: Cleaned surfaces must be rinsed with clean water to ensure no residue is retained. Cleaning and drying immediately using a cloth that leaves no lint ensures no water stains will be present.

- Storage Recommendations

- Lower Humidity: Keep stainless steel items within controlled humidity to minimize staining or mold growth risk.

- Use corrosion-resistant and non-metal shelving to reduce the likelihood of moisture. Additionally, do not allow the products to contact moist surfaces directly.

- Avoid Acidic or Salty Environments: Additional protective coating or wrapping in corrosion-inhibiting paper is suggested for enduring storage near coastal or industrial zones.

- Prevent Contact with Dissimilar Metals: During storage, stainless steel should not contact reactive metals such as aluminum or carbon steel to mitigate galvanic corrosion.

- Insights of The Key Data on The Longevity of Stainless Steel

- When combined with protective coverings, an enclosed storage area with controlled atmospheres can reduce corrosion rates by up to 90%.

- Follow these measures to maximize the longevity of stainless steel products and their aesthetic and functional qualities.

- As noted by ISSF research, proactive measures enhance the durability of stainless steel by 50%, lessening replacement expenditure considerably.

A study shows that stainless steel containing moisture with chloride ions, like water, is susceptible to corrosion 10 times faster than in fresh water.

References

- Design and Modelling of Vessel with Half-Pipe Coil

This study discusses the use of AISI 304L stainless steel in various applications.

Read more here - Comparison of Fatigue Performance Between Additively Manufactured and Wrought 304L Stainless Steel

This paper compares the fatigue performance of different manufacturing methods for 304L stainless steel.

Read more here - Non-Linear Harmonic Analysis of Material Magnetic Response for Monitoring Fatigue in Austenitic Steels

This research includes studies on 304L stainless steel and its fatigue properties.

Read more here

Frequently Asked Questions (FAQ)

Q: What is 304L Stainless Steel Coil, and how does it differ from 304 Stainless Steel?

A: 304L Stainless Steel Coil is a lower-carbon version of 304 stainless steel. It offers better weldability due to its reduced carbon content, minimizing the risk of carbide precipitation during welding. This makes it ideal for use in heavy-gauge components that require welding.

Q: Why is 304 Stainless Steel Coil preferred for specific applications?

A: 304 Stainless Steel Coil is favored for its excellent corrosion resistance, formability, and ease of fabrication. It is versatile and suitable for various applications, including kitchen equipment, chemical containers, and architectural paneling.

Q: How does cold-rolled stainless steel sheet differ from hot-rolled stainless steel?

A: Cold-rolled stainless Steel Sheet is processed at room temperature, resulting in a smoother surface finish and tighter tolerances compared to Hot-Rolled Stainless Steel, which is processed at high temperatures and is generally thicker and less precise.

Q: What are the typical applications for 316 and 316L Stainless Steel?

A: 316 and 316L Stainless Steel are commonly used in environments exposed to harsh chemicals, such as marine applications, chemical processing, and medical devices, due to their superior corrosion resistance and mechanical properties.

Q: What does the No.4 Finish mean in Stainless Steel products?

A: The No.4 Finish refers to a brushed finish with a fine-grit linear texture. It is commonly used in architectural and kitchen applications, providing an aesthetically pleasing matte appearance that is easier to maintain.

Q: What are the main characteristics of 430 Stainless Steel?

A: 430 Stainless Steel is a ferritic, straight chromium alloy with good corrosion resistance and formability. It is magnetic and typically used in automotive trim and appliance components applications.

Q: How do manufacturers and suppliers in China contribute to the Stainless Steel Coil market?

A: Chinese manufacturers and suppliers play a significant role in the global stainless steel coil market by providing a wide range of products at competitive prices, often offering customization and flexibility in terms of dimensions and finishes.

Q: What is the significance of the 2B Finish on Stainless Steel?

A: The 2B Finish is a standard surface finish for stainless steel. It is characterized by its smooth, reflective appearance, achieved through cold rolling followed by heat treatment. It is widely used due to its versatility and aesthetic appeal.

Q: How does 201 Stainless Steel compare to 304 Stainless Steel in terms of properties?

A: 201 Stainless Steel is a lower-cost alternative to 304, with slightly less corrosion resistance and formability. It is suitable for applications where cost is a factor and exposure to harsh environments is minimal.

Q: What are the benefits of using Stainless Steel tubes in construction?

A: Stainless Steel Tubes offer excellent strength, durability, and resistance to corrosion, making them ideal for structural applications, piping systems, and architectural elements. They also ensure longevity and reliability in various construction projects.