Get in touch with us

Leave a message

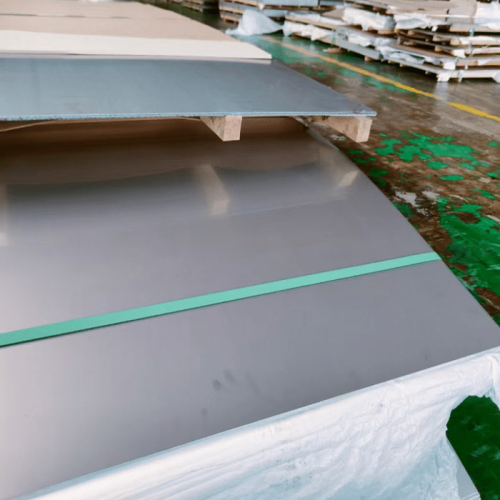

The MP159 Cobalt Alloy Plate, a high-performance cobalt-based alloy, offers exceptional strength, corrosion resistance, and durability. Renowned for its use in demanding environments, this cobalt chromium alloy excels in aerospace, medical, and industrial applications. Its unique cobalt alloy composition ensures reliability under extreme conditions, making it a preferred choice for professionals seeking robust materials.

Contact our sales team to request a quote for MP159 Cobalt Alloy Plate. Pricing terms are tailored based on order volume, specifications, and delivery requirements.

MP159 Cobalt Alloy Plate is widely used across industries due to its robust cobalt alloy properties. Key applications include:

| Element | Percentage (%) |

|---|---|

| Cobalt (Co) | Balance |

| Nickel (Ni) | 24.0 - 26.0 |

| Chromium (Cr) | 18.0 - 20.0 |

| Iron (Fe) | 8.0 - 10.0 |

| Molybdenum (Mo) | 6.0 - 8.0 |

| Titanium (Ti) | 0.6 - 1.0 |

| Property | Value |

|---|---|

| Tensile Strength | 1100 - 1300 MPa |

| Yield Strength | 900 - 1100 MPa |

| Elongation | 10 - 15% |

| Hardness (HRC) | 35 - 45 |

MP159 Cobalt Alloy Plate exhibits excellent resistance to acids, alkalis, and oxidative environments. It performs well in sulfuric and hydrochloric acid solutions but may require protective coatings in highly concentrated alkaline settings. This cobalt base alloy complies with environmental regulations, with no restricted substances in its composition.

While MP159 Cobalt Alloy Plate is highly versatile, certain limitations should be noted:

| Environment | Corrosion Rate (mm/year) |

|---|---|

| Atmospheric (Urban) | <0.01 |

| Seawater | 0.02 - 0.05 |

| 10% Sulfuric Acid | 0.1 - 0.3 |

| 5% Hydrochloric Acid | 0.2 - 0.5 |

MP159 Cobalt Alloy Plate supports various welding methods, including TIG (Tungsten Inert Gas) and MIG (Metal Inert Gas). Preheating to 200°C is recommended to minimize cracking. Fabrication techniques such as cutting, forming, and machining require high-precision tools due to the alloy’s toughness. Cobalt alloy round rod variants are also suitable for similar processes.

The MP159 Cobalt Alloy Plate has been a reliable choice for our turbine components, with excellent durability.

Anna K.

Aerospace Technician

This cobalt base alloy holds up exceptionally well in our acidic processing environments.

David M.

Chemical Engineer

The factory’s flexibility with custom orders and competitive cobalt alloy price made this a great purchase.

Emma T.

Procurement Officer

A: MP159 offers higher tensile strength and better corrosion resistance in acidic environments compared to Stellite, making it ideal for aerospace and medical applications.

A: It is used in aerospace for turbine blades, in medical for implants, and in industrial settings for chemical processing equipment.

A: It performs well up to 600°C but may lose some mechanical properties at higher temperatures.

A: Pricing depends on specifications and order volume. Contact our sales team for a detailed quote.

A: Yes, it adheres to global environmental standards with no restricted substances.

Professional manufacturer of premium specialty alloys, offering stainless steel, Hastelloy, nickel-based alloys and processing services. Delivering superior metallurgical solutions for aerospace, petrochemical, marine engineering and other demanding industries.