Get in touch with us

Leave a message

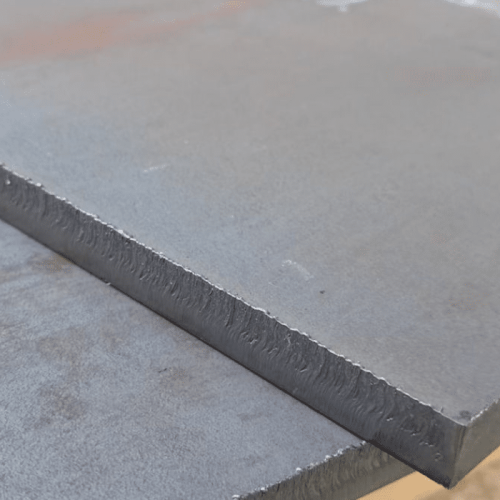

Stellite1 Cobalt Alloy Sheet, a premium cobalt-based alloy, is renowned for its exceptional wear resistance and high-temperature performance. Engineered for demanding environments, this cobalt chromium alloy is ideal for industries requiring durable, corrosion-resistant materials. Its unique cobalt alloy composition ensures reliability in extreme conditions, making it a top choice for industrial applications.

For a detailed quote on Stellite1 Cobalt Alloy Sheet, please contact our sales team. Pricing terms are tailored based on order volume and specifications. Reach out to discuss your requirements today.

Stellite1 Cobalt Alloy Sheet is widely used across industries due to its robust cobalt alloy uses. Key applications include:

| Element | Percentage (%) |

|---|---|

| Cobalt (Co) | Balance |

| Chromium (Cr) | 28.0 - 32.0 |

| Tungsten (W) | 11.0 - 13.0 |

| Carbon (C) | 2.0 - 2.7 |

| Iron (Fe) | ≤ 3.0 |

| Nickel (Ni) | ≤ 3.0 |

| Property | Value |

|---|---|

| Tensile Strength | 850 - 1000 MPa |

| Yield Strength | 600 - 750 MPa |

| Elongation | ≤ 1% |

| Hardness (HRC) | 50 - 58 |

Stellite1 Cobalt Alloy Sheet exhibits excellent resistance to acids, alkalis, and oxidative environments. It performs well in sulfuric and hydrochloric acid settings but may require caution in highly concentrated nitric acid. Environmentally, ensure compliance with regulations for cobalt-containing materials during disposal.

While highly durable, Stellite1 Cobalt Alloy Sheet has limitations:

| Environment | Corrosion Rate (mm/year) |

|---|---|

| Atmospheric (Urban) | <0.01 |

| Seawater | <0.05 |

| 10% Sulfuric Acid | 0.1 - 0.3 |

| 10% Hydrochloric Acid | 0.2 - 0.5 |

Stellite1 Cobalt Alloy Sheet supports various welding methods, including:

Fabrication involves water jet or laser cutting for precision. Forming is limited due to low ductility, so preheating is recommended to avoid cracking.

We’ve used Stellite1 Cobalt Alloy Sheet for turbine components, and the wear resistance is outstanding. The supplier’s customization options saved us time.

John M.

Aerospace Engineer

The cobalt alloy sheets performed perfectly in our cutting tools. Delivery was prompt, and the material quality exceeded expectations.

Lisa K.

Manufacturing Manager

Stellite1 sheets handled corrosive fluids in our pumps without issues. Highly recommend this cobalt chromium alloy for tough environments.

Ahmed R.

Oil & Gas Technician

A: Stellite1 has a higher carbon content, enhancing its hardness and wear resistance compared to other Stellite grades, making it ideal for abrasive environments.

A: Aerospace, oil & gas, and manufacturing industries benefit due to its high-temperature and corrosion-resistant properties.

A: Yes, its cobalt chrome composition is biocompatible, suitable for orthopedic implants.

A: Contact our sales team for lead times, which vary based on order specifications.

A: While Stellite1 sheets are ideal for flat applications, Round Bars and Rods suit cylindrical components like shafts, offering similar cobalt alloy properties.

Professional manufacturer of premium specialty alloys, offering stainless steel, Hastelloy, nickel-based alloys and processing services. Delivering superior metallurgical solutions for aerospace, petrochemical, marine engineering and other demanding industries.