Get in touch with us

Leave a message

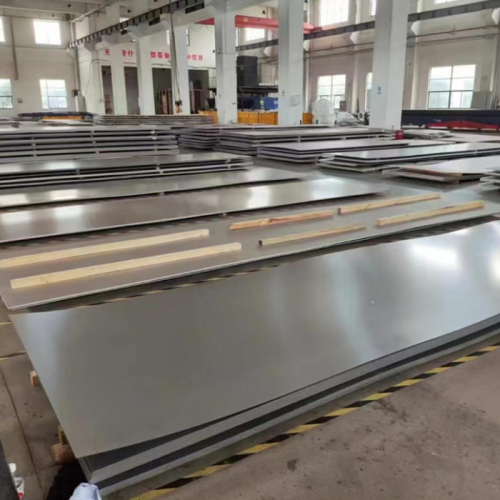

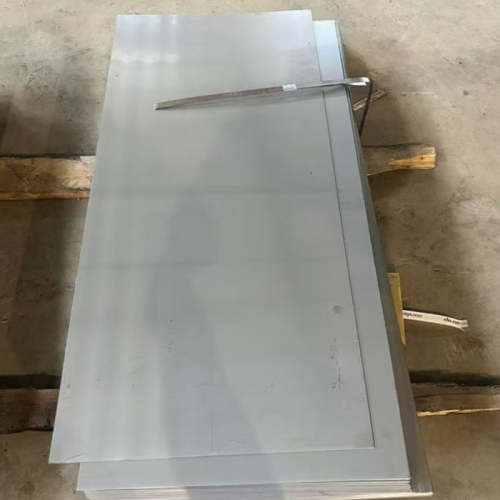

The Stellite100 Cobalt Alloy Sheet is a premium cobalt chromium alloy engineered for extreme durability. Known for its outstanding wear resistance, corrosion resistance, and high-temperature performance, this cobalt base alloy excels in harsh industrial settings. Its specialized cobalt alloy composition makes it a trusted choice for demanding applications.

To receive a tailored quote for Stellite100 Cobalt Alloy Sheet, reach out to our sales team via our website’s inquiry form. Pricing for this cobalt-based alloy depends on specifications, order size, and delivery terms.

This cobalt alloy serves critical roles in industries such as:

| Element | Percentage (%) |

|---|---|

| Cobalt (Co) | Balance |

| Chromium (Cr) | 28.0 - 32.0 |

| Tungsten (W) | 12.0 - 14.0 |

| Carbon (C) | 1.8 - 2.2 |

| Nickel (Ni) | ≤ 3.0 |

| Iron (Fe) | ≤ 3.0 |

| Property | Value |

|---|---|

| Tensile Strength | ≥ 900 MPa |

| Yield Strength | ≥ 600 MPa |

| Elongation | ≥ 5% |

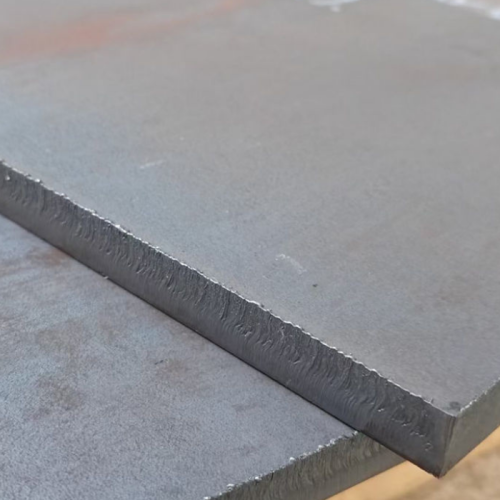

| Hardness (HRC) | 40 - 50 |

The Stellite100 Cobalt Alloy Sheet resists corrosion from acids like nitric and sulfuric, as well as alkalis. It meets environmental standards but should not be exposed to concentrated acidic solutions above 70°C for extended periods to avoid material degradation.

| Environment | Corrosion Resistance |

|---|---|

| Atmospheric (Air, Humidity) | Excellent |

| Mild Chemical (Dilute Acids) | Very Good |

| Seawater | Very Good |

| Oxidizing Gases (High Temp) | Good |

For Stellite100 Cobalt Alloy Sheet, use TIG or plasma arc welding with preheating to 250-350°C to prevent cracking. The alloy supports machining and forming, but its high hardness requires carbide or diamond-tipped tools.

The Stellite100 Cobalt Alloy Sheet performs flawlessly in our jet engines. Its wear resistance is top-notch.

Emma R.

Aerospace Technician

This cobalt chrome sheet is perfect for our reactor vessels. Corrosion resistance is outstanding.

David K.

Chemical Engineer

We trust this cobalt alloy for seawater-exposed parts. Durable and reliable.

Lisa P.

Marine Supplier

A: Stellite100 Cobalt Alloy Sheet has higher carbon and tungsten content, enhancing wear resistance compared to other cobalt-based alloys.

A: Stellite100 Cobalt Alloy Sheet offers similar cobalt alloy properties but is better suited for flat applications, unlike round bars or round rods.

A: It’s used in aerospace, oil & gas, medical, and industrial manufacturing for its cobalt alloy uses.

A: Stellite100 has a higher carbon content, enhancing its hardness and wear resistance compared to other cobalt based alloys.

A: Both share similar cobalt alloy composition, but the sheet form is ideal for flat applications.

Professional manufacturer of premium specialty alloys, offering stainless steel, Hastelloy, nickel-based alloys and processing services. Delivering superior metallurgical solutions for aerospace, petrochemical, marine engineering and other demanding industries.

©2025 alloy-materials.com COPYRIGHT ALL RIGHT RESERVED.