Get in touch with us

Leave a message

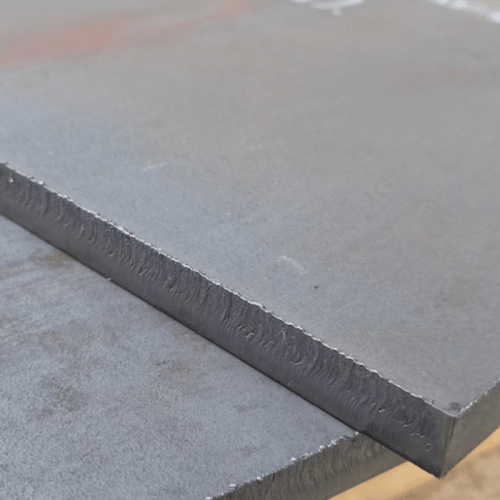

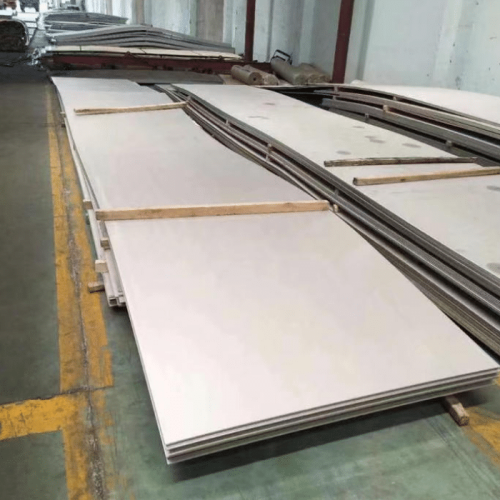

The Stellite12 Cobalt Alloy Sheet is a premium cobalt-based alloy designed for exceptional wear and corrosion resistance. Known for its durability, this cobalt chromium alloy is ideal for demanding industrial applications, offering superior performance in high-temperature and abrasive environments. Its unique cobalt alloy composition ensures reliability across various industries.

For detailed pricing and quotes on Stellite12 Cobalt Alloy Sheet, please contact our sales team. Pricing terms are flexible based on order volume and customization requirements.

The Stellite12 Cobalt Alloy Sheet is widely used in industries such as:

| Element | Percentage (%) |

|---|---|

| Cobalt (Co) | Balance |

| Chromium (Cr) | 28.0 - 32.0 |

| Tungsten (W) | 7.0 - 9.0 |

| Carbon (C) | 1.1 - 1.7 |

| Nickel (Ni) | ≤ 3.0 |

| Iron (Fe) | ≤ 3.0 |

| Property | Value |

|---|---|

| Tensile Strength | 950 MPa (min) |

| Yield Strength | 600 MPa (min) |

| Elongation | 10% (min) |

| Hardness | 40 - 48 HRC |

The Stellite12 Cobalt Alloy Sheet exhibits excellent resistance to acids (e.g., sulfuric and hydrochloric) and alkalis, making it suitable for chemical processing environments. However, it is not recommended for prolonged exposure to highly oxidizing acids like nitric acid. Ensure compliance with environmental regulations regarding cobalt usage in sensitive applications.

| Environment | Corrosion Resistance |

|---|---|

| Atmospheric | Excellent |

| Mild Chemical (e.g., dilute acids) | Very Good |

| Seawater | Good |

| Oxidizing Acids | Moderate |

Recommended welding methods for Stellite12 Cobalt Alloy Sheet include:

Fabrication techniques include cutting, forming, and machining. Preheating and post-weld heat treatment are advised to minimize cracking. Use high-speed steel or carbide tools for machining.

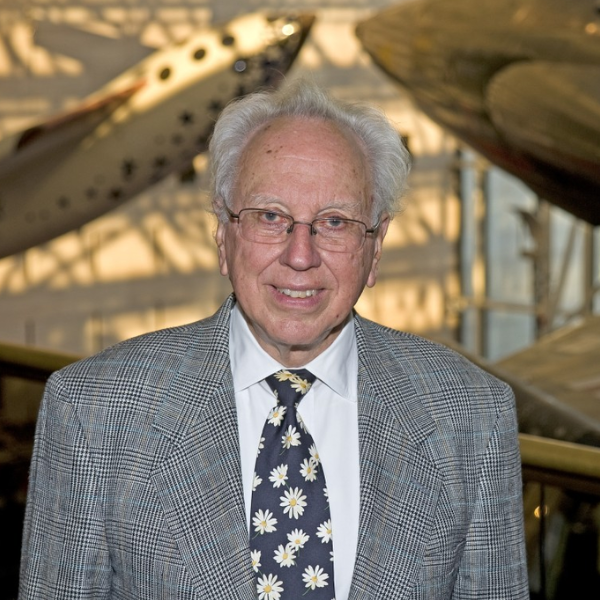

The Stellite12 Cobalt Alloy Sheet has been a game-changer for our turbine components. Its wear resistance is unmatched, and the China factory provided excellent support.

John D.

Aerospace Engineer

We switched to this cobalt chromium alloy for our reactor linings, and the corrosion resistance is impressive. Highly recommend this manufacturer.

Emily R.

Chemical Plant Manager

The durability of this cobalt base alloy in harsh environments is outstanding. Great value for the cobalt alloy price.

Michael S.

Oil & Gas Technician

A: Stellite12 offers a balanced combination of wear and corrosion resistance, with a higher carbon content than Stellite 6, making it ideal for abrasive environments.

A: It’s widely used in aerospace, oil and gas, power generation, chemical processing, and medical industries.

A: It performs well up to 800°C but may lose hardness beyond this threshold.

A: Stellite12 outperforms stainless steel in wear and corrosion resistance but is more expensive.

A: Options include 2B, No.1, polished, and brushed finishes, customizable to project needs.

Professional manufacturer of premium specialty alloys, offering stainless steel, Hastelloy, nickel-based alloys and processing services. Delivering superior metallurgical solutions for aerospace, petrochemical, marine engineering and other demanding industries.