Get in touch with us

Leave a message

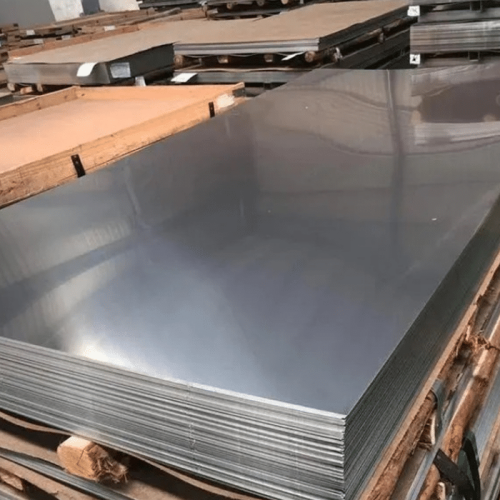

The Stellite20 Cobalt Alloy Plate is a high-performance cobalt chromium alloy renowned for its exceptional wear and corrosion resistance. Engineered for extreme conditions, this cobalt base alloy is ideal for industries like mining, oil and gas, and power generation. Its robust cobalt alloy composition ensures durability and reliability in demanding applications.

For pricing details on Stellite20 Cobalt Alloy Plate, reach out to our sales team. We provide competitive pricing terms, including discounts for bulk orders of Cobalt Based Alloys. Request a quote to discuss your needs.

The Stellite20 Cobalt Alloy Plate is a versatile material used in industries requiring robust cobalt alloy properties. Key applications include:

| Element | Percentage (%) |

|---|---|

| Cobalt (Co) | Balance |

| Chromium (Cr) | 31.0 - 35.0 |

| Tungsten (W) | 16.0 - 18.0 |

| Carbon (C) | 2.2 - 2.8 |

| Nickel (Ni) | ≤ 2.0 |

| Iron (Fe) | ≤ 2.0 |

| Property | Value |

|---|---|

| Tensile Strength | ≥ 900 MPa |

| Yield Strength | ≥ 700 MPa |

| Elongation | ≥ 8% |

| Hardness (HRC) | 50 - 56 |

The Stellite20 Cobalt Alloy Plate exhibits excellent resistance to acids, alkalis, and oxidative environments, making it suitable for corrosive industrial settings. It performs well against nitric and phosphoric acids but may require protective coatings in concentrated alkaline solutions. Due to its cobalt content, cobalt alloy uses may be subject to environmental regulations in certain regions. Verify compliance with local standards.

While the Stellite20 Cobalt Alloy Plate is highly durable, note the following limitations:

| Environment | Corrosion Resistance |

|---|---|

| Atmospheric (Industrial) | Excellent |

| Mild Chemical (Dilute Acids) | Excellent |

| Seawater | Very Good |

| Concentrated Alkalis | Moderate (Coating Advised) |

The Stellite20 Cobalt Alloy Plate can be welded using TIG or MIG methods, with preheating to 250°C recommended to avoid cracking. Forming techniques like cutting and bending are achievable with appropriate equipment. For detailed guidance on cobalt alloy composition, consult our technical team.

The Stellite20 Cobalt Alloy Plate has significantly extended the life of our crusher components. Its wear resistance is outstanding, and the support team was excellent.

Mark R.

Mining Engineer

We use Stellite plates for pump liners, and they perform flawlessly in corrosive environments. A reliable cobalt chrome solution.

Sarah L.

Oil and Gas Manager

The quality of these Cobalt Based Alloys is unmatched, and the customization options streamlined our process. Worth the cobalt alloy price.

Chen Y.

Procurement Lead

A: The Stellite20 Cobalt Alloy Plate has a higher carbon and tungsten content, offering superior wear resistance compared to softer cobalt based alloys.

A: Mining, oil and gas, and power generation benefit from its robust cobalt alloy properties.

A: Welding is manageable with TIG or MIG, provided preheating is applied correctly.

A: Reach out to our sales team for customized pricing and specifications for Stellite.

A: The Stellite20 Cobalt Alloy Plate offers better wear and corrosion resistance but at a higher cobalt alloy price.

Professional manufacturer of premium specialty alloys, offering stainless steel, Hastelloy, nickel-based alloys and processing services. Delivering superior metallurgical solutions for aerospace, petrochemical, marine engineering and other demanding industries.