Get in touch with us

Leave a message

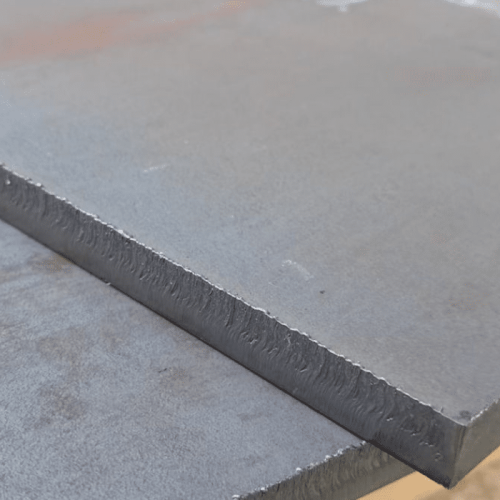

The Stellite3 Cobalt Alloy Sheet is a high-performance cobalt-based alloy renowned for its exceptional wear resistance, high-temperature stability, and corrosion resistance. Manufactured by our leading China enterprise, this cobalt-chromium alloy is ideal for demanding industrial environments, offering durability and reliability in applications such as aerospace, power generation, and chemical processing.

For competitive pricing on Stellite3 Cobalt Alloy Sheet, contact our sales team for a customized quote. Pricing terms are flexible based on order volume and specifications. Reach out today to discuss your cobalt alloy needs.

The Stellite3 Cobalt Alloy Sheet is widely used across industries due to its robust cobalt alloy properties. Key applications include:

| Element | Percentage (%) |

|---|---|

| Cobalt (Co) | Balance |

| Chromium (Cr) | 29.0-31.0 |

| Tungsten (W) | 11.0-13.0 |

| Carbon (C) | 2.0-2.7 |

| Nickel (Ni) | ≤3.0 |

| Iron (Fe) | ≤3.0 |

| Property | Value |

|---|---|

| Tensile Strength | 860 MPa (min) |

| Yield Strength | 620 MPa (min) |

| Elongation | 5% (min) |

| Hardness | 48-55 HRC |

The Stellite3 Cobalt Excess Alloy Sheet exhibits excellent resistance to acids, alkalis, and oxidizing environments. It performs well in sulfuric and hydrochloric acid solutions but may require caution in highly concentrated nitric acid. Environmental restrictions include avoiding prolonged exposure to extreme saline conditions, which could accelerate pitting corrosion.

While Stellite3 Cobalt Alloy Sheet excels in many environments, note the following limitations:

| Environment | Corrosion Rate (mm/year) |

|---|---|

| Atmospheric (Urban) | <0.01 |

| Mild Chemical (5% H₂SO₄) | 0.02-0.05 |

| Seawater | 0.05-0.1 |

Stellite3 Cobalt Alloy Sheet supports various welding methods, including:

Fabrication techniques include cutting (laser or waterjet), forming, and machining. Preheating to 200-300°C is recommended to prevent cracking during forming.

The Stellite3 Cobalt Alloy Sheet from this China manufacturer has been a game-changer for our turbine components. Its wear resistance is unmatched!

John M.

Aerospace Engineer

We switched to Stellite sheets for our reactor linings, and the corrosion resistance has significantly reduced downtime.

Sarah L.

Chemical Plant Manager

The durability of this cobalt-chromium alloy in harsh drilling conditions is impressive. Highly recommend this distributor.

Mike T.

Oil & Gas Technician

A: Stellite3 has a higher carbon content, enhancing wear resistance but reducing ductility compared to alloys like Stellite6.

A: Aerospace, power generation, chemical processing, and oil and gas industries rely on its durability.

A: Yes, up to 1000°C, but prolonged exposure may affect hardness.

A: Stellite3 offers superior wear and corrosion resistance but at a higher cost.

A: Lead times vary based on order size; contact our team for details.

Professional manufacturer of premium specialty alloys, offering stainless steel, Hastelloy, nickel-based alloys and processing services. Delivering superior metallurgical solutions for aerospace, petrochemical, marine engineering and other demanding industries.