Get in touch with us

Leave a message

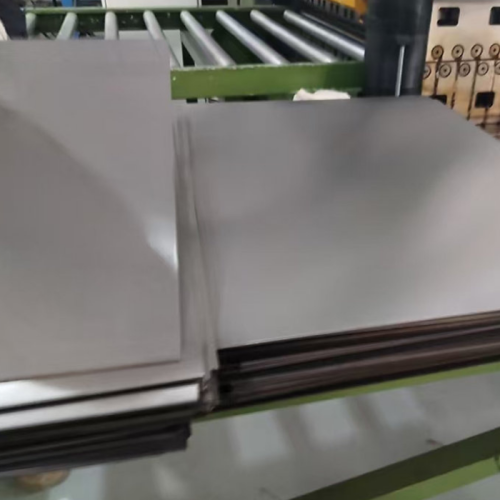

The Stellite31 Cobalt Alloy Plate is a high-performance cobalt chromium alloy designed for extreme environments. Renowned for its exceptional wear resistance, corrosion resistance, and high-temperature stability, this cobalt base alloy is a top choice for industries requiring durable materials. Its unique cobalt alloy composition ensures reliability in demanding applications, making it a preferred material for manufacturers worldwide.

For competitive pricing on Stellite31 Cobalt Alloy Plate, please contact our sales team through our website’s inquiry form. Pricing terms for this cobalt-based alloy are tailored based on order volume, specifications, and delivery requirements.

This cobalt alloy is widely used in industries such as:

| Element | Percentage (%) |

|---|---|

| Cobalt (Co) | Balance |

| Chromium (Cr) | 25.0 - 27.0 |

| Nickel (Ni) | 9.0 - 11.0 |

| Tungsten (W) | 7.0 - 8.0 |

| Carbon (C) | 0.45 - 0.55 |

| Iron (Fe) | ≤ 2.0 |

| Property | Value |

|---|---|

| Tensile Strength | ≥ 800 MPa |

| Yield Strength | ≥ 500 MPa |

| Elongation | ≥ 10% |

| Hardness (HRC) | 30 - 40 |

The Stellite31 Cobalt Alloy Plate offers excellent resistance to acids (e.g., sulfuric and hydrochloric) and alkalis, making it ideal for chemical processing environments. It complies with environmental regulations, but users should avoid prolonged exposure to highly concentrated acidic solutions above 80°C to prevent potential degradation.

| Environment | Corrosion Resistance |

|---|---|

| Atmospheric (Air, Humidity) | Excellent |

| Mild Chemical (Dilute Acids) | Very Good |

| Seawater | Good |

| High-Temperature Oxidizing Gases | Excellent |

Recommended welding methods for Stellite31 Cobalt Alloy Plate include TIG (Tungsten Inert Gas) and plasma arc welding. Preheating to 200-300°C is advised to minimize cracking. The alloy supports forming processes like cutting, bending, and machining, though specialized tools are required due to its hardness.

The Stellite31 Cobalt Alloy Plate has been a game-changer for our turbine components. Its durability in high-temperature environments is unmatched.

John M.

Aerospace Engineer

We’ve used this cobalt chrome plate for reactor linings, and its corrosion resistance is exceptional. Highly recommend!

Sarah L.

Chemical Plant Manager

Reliable and customizable. The cobalt alloy properties make it perfect for our drilling equipment.

Mike T.

Oil & Gas Supplier

A: Stellite31 Cobalt Alloy Plate has a unique balance of chromium, nickel, and tungsten, offering superior wear and corrosion resistance compared to other cobalt-based alloys.

A: Aerospace, power generation, chemical processing, and oil and gas industries rely on its durability.

A: Lead times vary based on specifications but typically range from 4-6 weeks.

A: While Stellite31 Cobalt Alloy Plate has a higher initial cost, its longevity reduces maintenance expenses, unlike round bars or round rods.

A: Use TIG welding with preheating to avoid cracking, and ensure proper ventilation.

Professional manufacturer of premium specialty alloys, offering stainless steel, Hastelloy, nickel-based alloys and processing services. Delivering superior metallurgical solutions for aerospace, petrochemical, marine engineering and other demanding industries.

©2025 alloy-materials.com COPYRIGHT ALL RIGHT RESERVED.