Get in touch with us

Leave a message

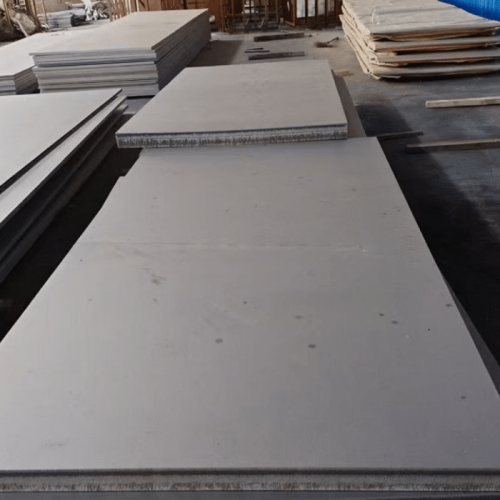

The Stellite6 Cobalt Alloy Plate is a versatile cobalt-based alloy known for its excellent corrosion resistance, wear resistance, and high-temperature performance. Produced by our trusted China manufacturer, this cobalt-chromium alloy is ideal for industries requiring durable materials, such as aerospace, oil and gas, and chemical processing.

Contact our sales team for a tailored quote on Stellite6 Cobalt Alloy Plate. Pricing is competitive and based on order specifications. Reach out to explore your cobalt alloy needs.

The Stellite6 Cobalt Alloy Plate is a preferred choice for industries leveraging its robust cobalt alloy properties. Common applications include:

| Element | Percentage (%) |

|---|---|

| Cobalt (Co) | Balance |

| Chromium (Cr) | 27.0-32.0 |

| Tungsten (W) | 4.0-6.0 |

| Carbon (C) | 0.9-1.4 |

| Nickel (Ni) | ≤3.0 |

| Iron (Fe) | ≤3.0 |

| Property | Value |

|---|---|

| Tensile Strength | 950 MPa (min) |

| Yield Strength | 550 MPa (min) |

| Elongation | 10% (min) |

| Hardness | 36-45 HRC |

The Stellite6 Cobalt Alloy Plate offers superior resistance to acids, alkalis, and oxidizing agents. It performs well in sulfuric and phosphoric acid environments but may face challenges in concentrated nitric acid. Environmental restrictions include avoiding prolonged exposure to highly saline or chloride-rich conditions to prevent localized corrosion.

While the Stellite6 Cobalt Alloy Plate is highly versatile, note these limitations:

| Environment | Corrosion Rate (mm/year) |

|---|---|

| Atmospheric (Industrial) | <0.01 |

| Mild Chemical (10% H₂SO₄) | 0.01-0.03 |

| Seawater | 0.03-0.08 |

The Stellite6 Cobalt Alloy Plate supports multiple welding methods, including:

Fabrication includes laser cutting, forming, and machining. Preheating to 150-250°C is advised to minimize cracking risks during processing.

The Stellite6 Cobalt Alloy Plate from this China factory has exceptional durability for our engine parts. Highly reliable!

Emma R.

Aerospace Technician

We use Stellite plates in our reactors, and the corrosion resistance has drastically improved our operational efficiency.

David K.

Chemical Engineer

This cobalt-chromium alloy performs flawlessly in seawater applications. Great support from the manufacturer.

Liam S.

Marine Equipment Supplier

A: Stellite6 has lower carbon content, offering better ductility but slightly less wear resistance than Stellite3.

A: Aerospace, oil and gas, chemical processing, power generation, and marine industries benefit from its properties.

A: Yes, up to 900°C, though extended exposure may affect performance.

A: Stellite6 offers superior wear resistance but may be less cost-effective.

A: Lead times depend on order size; contact our team for specifics.

Professional manufacturer of premium specialty alloys, offering stainless steel, Hastelloy, nickel-based alloys and processing services. Delivering superior metallurgical solutions for aerospace, petrochemical, marine engineering and other demanding industries.